Description

1. Product Description

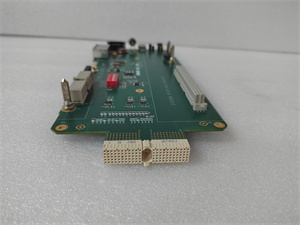

TRICONEX 3704 is a high-reliability analog input module from TRICONEX, a renowned brand specializing in safety-critical industrial automation solutions. Designed for use in the Tricon triple modular redundancy (TMR) system, the 3704 module is engineered to acquire and process analog signals from field devices with precision and integrity. This module is ideal for applications requiring accurate measurement and monitoring of process variables such as temperature, pressure, and flow in industries like oil and gas, chemical processing, and power generation. The TRICONEX 3704 ensures robust performance in harsh environments, thanks to its triple modular redundancy design, which provides fault tolerance and continuous operation even in the presence of single-point failures.

2. Product Parameters

| Parameter | Details |

|---|---|

| Module Type | Analog Input Module (TMR-based) |

| Signal Types | 4-20 mA, 0-10 V, RTD (Pt100, Pt500, Pt1000), thermocouples (J, K, T, E) |

| Channels | 16 isolated channels (500 V DC isolation per channel) |

| Resolution | 16-bit analog-to-digital conversion |

| Accuracy | ±0.1% of full-scale reading |

| Redundancy | Triple modular redundancy (TMR) with self-diagnostic capabilities |

| Communication | Proprietary Tricon backplane communication |

| Operating Temperature | -40°C to +65°C (-40°F to +149°F) |

| Certifications | SIL 3 (IEC 61508), ATEX, IECEx (hazardous area approval) |

TRICONEX 3704

3. Advantages and Features

The TRICONEX 3704 stands out for its multiplexed signal compatibility and advanced diagnostics. Its ability to handle multiple signal types (current, voltage, RTD, thermocouples) eliminates the need for separate modules, simplifying inventory and installation. The module’s TMR architecture ensures that each channel is triplicated, with built-in self-test (BIST) functionality that continuously monitors for faults. For example, in a petrochemical plant, the 3704 successfully detected a faulty RTD sensor channel while maintaining full system operation, allowing maintenance to be scheduled without disrupting production. The 16-bit resolution and ±0.1% accuracy ensure precise process monitoring, critical for maintaining quality and safety in regulated environments.

4. Application Fields and Cases

The 3704 module is widely applied in industries requiring high-integrity analog signal acquisition, including:

- Oil and Gas: Wellhead monitoring, pipeline pressure control, and environmental parameter tracking.

- Chemical Processing: Reactor temperature control, distillation column analytics, and safety interlock systems.

- Power Generation: Steam turbine performance monitoring, boiler efficiency optimization, and renewable energy asset management.

In a notable case, a large-scale pharmaceutical manufacturing facility deployed the TRICONEX 3704 to monitor critical process parameters in sterile production lines. The module’s fault-tolerant design ensured uninterrupted data acquisition during a simulated channel failure, preventing false alarms and maintaining compliance with FDA regulations. The high accuracy of the module also reduced variability in batch processes, improving yield by 5%.

5. Competitor Comparison

Compared to non-redundant analog input modules, the TRICONEX 3704 offers unmatched reliability through its TMR architecture, reducing the risk of unplanned downtime caused by single-component failures. Its wide range of supported signal types and built-in isolation (500 V DC per channel) provide greater flexibility than single-function modules, while the SIL 3 certification ensures compliance with the most stringent safety standards. The module’s rugged design for extreme temperatures and hazardous areas also outperforms many competitors in harsh industrial environments.

TRICONEX 3704

6. Selection Suggestions

When selecting the TRICONEX 3704, consider:

- Signal Requirements: Ensure the module supports the specific analog signals (e.g., RTD, thermocouple) and voltage/current ranges of your field devices.

- Redundancy Needs: Evaluate whether TMR architecture is necessary for your safety integrity level (SIL) and operational continuity requirements.

- Channel Density: Match the module’s 16-channel capacity to the scale of your system to avoid over-provisioning or underutilization.

- Environmental Conditions: Confirm that the module’s temperature range and hazardous area certifications align with your installation environment (e.g., explosion-proof zones).

7. Precautions

- Cabling: Use shielded twisted-pair cables for analog signals to minimize electromagnetic interference (EMI) and ensure signal integrity.

- Grounding: Follow TRICONEX’s guidelines for proper grounding of the module and field devices to prevent ground loops.

- Calibration: Regularly calibrate the module using traceable standards to maintain accuracy, especially in high-precision applications like pharmaceutical or food processing.

- Firmware Updates: Apply firmware updates only during scheduled maintenance windows, using validated procedures to avoid disrupting active processes.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.