Description

Product Overview

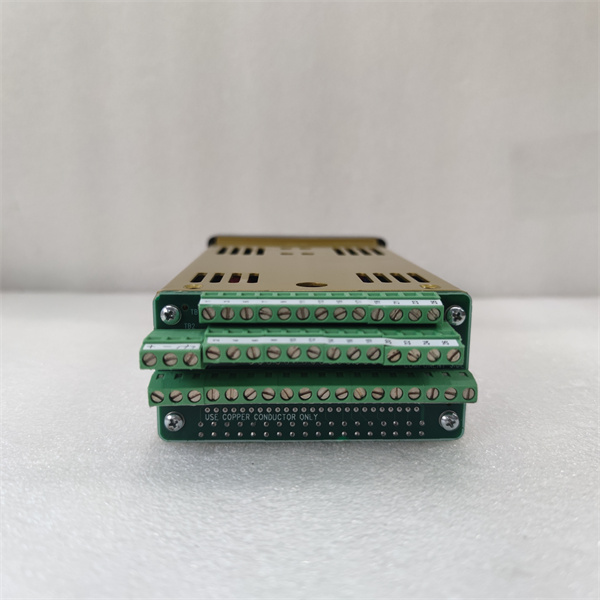

The WATLOW CLS216 is a sophisticated temperature control device designed to provide precise and reliable thermal management solutions across a wide array of industrial applications. As a key offering from Watlow, a trusted leader in thermal control technologies, the CLS216 is engineered to meet the diverse and exacting requirements of modern industries. This product serves as an essential component for processes where maintaining accurate temperature conditions is crucial for product quality, process efficiency, and overall operational safety.

The WATLOW CLS216 is equipped with advanced control algorithms and a user – friendly interface, enabling seamless integration into various industrial systems. Whether it’s regulating the temperature in high – temperature furnaces used in metal processing, maintaining the delicate temperature – sensitive environments in pharmaceutical manufacturing, or controlling the heat in electronic assembly processes, the CLS216 ensures consistent and precise temperature control. Its robust build quality and innovative features make it a reliable choice for industries seeking to optimize their thermal control processes and enhance productivity.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | CLS216 |

| Manufacturer | WATLOW |

| Product Type | Temperature Controller |

| Input Types | Thermocouple (J, K, T, E, R, S, B, N), RTD (Pt100, Ni1000), mV, V |

| Control Accuracy | ±0.15°C (typical) |

| Output Types | Relay, SSR drive, 4 – 20 mA, 0 – 10 V |

| Control Modes | On/Off, PID, Adaptive PID, Ramp – Soak |

| Communication Protocols | Modbus RTU, Ethernet/IP |

| Power Supply | 100 – 240 VAC, 50/60 Hz |

| Operating Temperature | -10°C – 55°C |

| Dimensions | 96mm x 96mm x 120mm (panel – mount) |

| Weight | 0.48 kg |

| Display | 4 – digit, 7 – segment LED for temperature, alphanumeric LED for status indication |

WATLOW ANAFAZE CLS208 208-C10000CA

Main Features and Advantages

Precise Temperature Regulation

The WATLOW CLS216 offers exceptional control accuracy of ±0.15°C, ensuring that industrial processes are maintained at the exact temperature required. In applications such as semiconductor manufacturing, where even minor temperature fluctuations can impact product quality, its advanced PID and Adaptive PID control modes continuously adjust the output to minimize variations. This results in stable and precise temperature control, enabling consistent production of high – quality products.

Versatile Connectivity Options

With support for a wide range of input types, the CLS216 can interface with various temperature sensors, providing flexibility for different industrial setups. Its multiple output types allow seamless connection to heating and cooling devices, giving users the freedom to customize the control system according to their specific needs. Additionally, the inclusion of Modbus RTU and Ethernet/IP communication protocols enables easy integration into industrial networks, facilitating remote monitoring and control. This allows operators to access real – time temperature data, adjust setpoints, and configure parameters from a centralized location, enhancing overall process management efficiency.

User – Friendly Operation

The CLS216 features a clear and intuitive display, with a 4 – digit, 7 – segment LED for temperature display and an alphanumeric LED for status indication. Its straightforward menu structure simplifies the configuration process, allowing users to quickly set up control parameters, select input and output types, and choose control modes. Even operators with limited technical knowledge can easily operate and maintain the WATLOW CLS216, reducing the learning curve and minimizing the risk of incorrect settings. This user – centric design ensures smooth operation and reduces the likelihood of errors, contributing to improved productivity.

WATLOW ANAFAZE CLS208 208-C10000CA

Application Field

In the pharmaceutical industry, the WATLOW CLS216 plays a vital role in controlling the temperature of reactors, drying ovens, and storage facilities. Precise temperature control is essential for drug synthesis, the drying of pharmaceutical powders, and the preservation of temperature – sensitive medications. The CLS216 ensures that these processes are carried out within the required temperature ranges, helping pharmaceutical companies meet strict quality and regulatory standards.

For metal processing industries, the CLS216 is used to regulate the temperature in heat treatment processes like annealing, quenching, and tempering. Accurate temperature control during these processes is crucial for achieving the desired mechanical properties of metals. Whether it’s a large – scale industrial furnace or a smaller – batch heat – treating unit, the WATLOW CLS216 provides the precision needed to produce high – quality metal components with consistent performance.

In the electronics manufacturing sector, the CLS216 is employed to control the temperature in soldering ovens, reflow processes, and component testing. Maintaining precise temperatures is essential to prevent damage to delicate electronic components and ensure proper soldering and assembly. The CLS216 helps electronics manufacturers achieve optimal temperature control, improving product yield and quality.

Related Products

- WATLOW CLS116: A more basic version of the CLS216, offering similar functionality but with reduced processing power and fewer input/output options. It is suitable for smaller – scale applications or those with less complex temperature control requirements.

- WATLOW CLS316: An upgraded model with enhanced features, such as higher control accuracy, more advanced communication capabilities, and additional input/output channels. It is designed for more demanding industrial applications that require top – tier performance and flexibility.

- WATLOW EZ – Zone® F4T: An entry – level temperature controller from Watlow, providing basic temperature control functions at a lower cost. It is ideal for simpler applications where high – end features and extreme accuracy are not critical.

- WATLOW PM3 Power Module: A power – control module that can be used in conjunction with the CLS216to enhance its power – handling capabilities. It helps in driving high – power heating or cooling devices and optimizing the energy efficiency of the temperature control system.

- WATLOW XTRM® Temperature Transmitter: A complementary product that can be paired with the CLS216to improve the accuracy and reliability of temperature sensing. The XTRM® transmitter provides high – quality temperature signals to the controller, ensuring more precise control in industrial processes.

Installation and Maintenance

Pre – installation preparation: Before installing the WATLOW CLS216, carefully review the installation manual. Ensure that the installation environment meets the specified temperature, humidity, and electrical requirements. Select an appropriate location on the control panel for panel – mount installation, ensuring proper ventilation around the controller. Prepare all necessary tools, including screwdrivers, wire strippers, and cable connectors. Connect the power supply cable to a stable 100 – 240 VAC source within the specified tolerance range. Then, connect the temperature sensor to the appropriate input terminals according to the sensor type and the provided wiring diagram. Configure the input type settings on the controller to match the connected sensor. If using communication features, connect the communication cables and configure the relevant protocol settings, such as baud rate and device address.

Maintenance recommendations: Regularly inspect the WATLOW CLS216 for any signs of abnormal operation, such as incorrect temperature readings, erratic output behavior, or error messages on the display. Check the tightness of all cable connections, including power, sensor, and communication cables, periodically to ensure reliable operation. Clean the exterior of the controller to remove dust and debris, especially if it is installed in a dusty environment. Calibrate the controller at regular intervals as per the manufacturer’s recommendations to maintain its accuracy. If any issues are detected, refer to the troubleshooting guide in the product manual or contact Watlow’s technical support team for assistance. Keep records of all maintenance activities, including inspection dates, calibration results, and any component replacements, for future reference.

Product Guarantee

Watlow stands firmly behind the quality of the WATLOW CLS216. The product undergoes stringent quality control procedures during manufacturing to meet and exceed industry standards. Watlow offers a comprehensive warranty, typically covering a specified period against manufacturing defects. In the event of a defect within the warranty period, Watlow will provide free repair or replacement services. Additionally, Watlow’s dedicated technical support team is available to assist customers with any questions regarding installation, operation, and maintenance. Whether it’s helping with complex system integration, resolving technical issues, or providing advice on optimizing the performance of the CLS216, Watlow is committed to ensuring that customers can rely on this product for their temperature – control needs in industrial applications.