Description

Key Technical Specifications

-

Model Number: 1C31222G01

-

Manufacturer: Emerson (formerly Westinghouse)

-

Number of Channels: 16 independent relay outputs

-

Output Rating: 250V AC, 30A per channel (resistive load)

-

Contact Material: Silver cadmium oxide (enhanced arc resistance)

-

Isolation: Galvanic isolation (channel-to-logic and channel-to-channel)

-

Operating Temperature: –40°C to +70°C (IEC 60068-2 compliant)

-

Storage Temperature: –55°C to +85°C

-

Humidity Range: 0–95% RH (non-condensing)

-

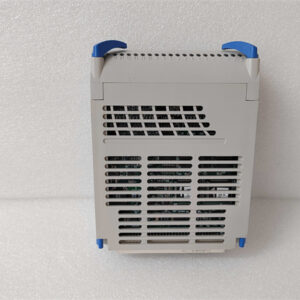

Protection Class: IP20 (dust-resistant, touch-safe)

-

Mounting: DIN rail or panel mount (compatible with Ovation EMOD bases)

-

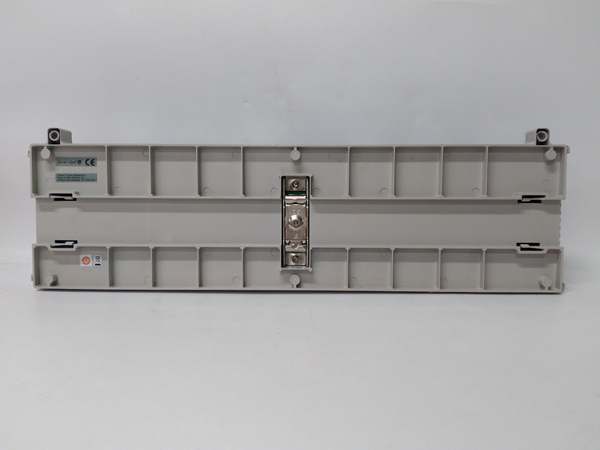

Dimensions: 42.4 × 12.6 × 10.8 cm (1.67 × 4.96 × 4.25 inches)

-

Weight: ~0.8 kg (1.76 lbs)

Field Application & Problem Solved

In industrial settings—from power plants to chemical refineries—control systems rely on hard-wired relay outputs to trigger high-power devices like motor starters, pneumatic valves, and alarm systems. The biggest challenge with legacy systems is finding a relay module that balances high current capacity (for heavy loads) with electrical isolation (to protect sensitive DCS logic from field transients). Solid-state outputs often fail here: they can’t handle 30A loads reliably, and their lack of true galvanic isolation leaves the controller vulnerable to voltage spikes.

The 1C31222G01 solves this by combining mechanical relay contacts (for high-current switching) with galvanic isolation (to separate field voltages from the DCS). You’ll find it in:

-

Power generation: Controlling boiler feedwater pumps, turbine lube oil systems, and generator circuit breakers.

-

Chemical/petrochemical: Actuating process valves (e.g., gate valves, globe valves) and starting large compressors.

-

Manufacturing: Driving conveyor belts, robotic arms, and assembly line equipment.

Its core value is reliability in mission-critical applications. Unlike solid-state alternatives, mechanical relays in the 1C31222G01 can handle frequent switching (up to 100,000 cycles) without degradation. The isolation also prevents field-induced noise (e.g., from nearby motors) from corrupting DCS signals—something we learned the hard way in a refinery where unisolated outputs caused intermittent valve malfunctions.

Installation & Maintenance Pitfalls (Expert Tips)

1. Skipping Isolation Checks

A common rookie mistake is assuming the module’s isolation is “good enough.” Always verify channel-to-channel isolation with a megger (insulation tester) before installation. We once had a client skip this step, and a faulty relay in one channel caused a ground loop that took down the entire DCS rack. The 1C31222G01’s isolation is rated for 1500V AC—test it to ensure it meets spec.

2. Ignoring Contact Ratings

The 30A rating is for resistive loads (e.g., heaters). If you’re switching inductive loads (e.g., motors, solenoids), derate the current by 50% (15A max). Inductive loads generate back EMF that damages relay contacts over time—we’ve seen this happen in a paper mill where a 30A relay was used to start a 20A motor, leading to welded contacts after six months.

3. Poor Wiring Practices

Use twisted-pair cables for field wiring to reduce electromagnetic interference (EMI). Avoid running relay output wires alongside power cables—this is a classic cause of “ghost” trips (relays activating without a command). Also, label each terminal clearly: nothing wastes more time than tracing a wire in a crowded cabinet only to find it’s connected to the wrong channel.

4. Forgetting Hot-Swap Capability

The 1C31222G01 is designed for hot-swapping (replacing modules without shutting down the system). But if you don’t follow the sequence—remove the module from the base, wait 5 seconds, then insert the new one—you risk damaging the backplane. We had a junior engineer yank a module out mid-operation, which fried the backplane connector. Now we train techs to always follow the “wait 5 seconds” rule.

Technical Deep Dive & Overview

The 1C31222G01 is a modular relay output base designed exclusively for Emerson’s Ovation Distributed Control System (DCS). It acts as a bridge between the DCS’s low-voltage digital signals (24V DC) and the high-voltage/high-current requirements of field devices. Here’s how it works:

-

Signal Reception: The Ovation controller sends a digital command (e.g., “start pump”) to the 1C31222G01 via the backplane.

-

Relay Activation: The module’s internal circuitry energizes the corresponding relay coil (24V DC), closing the contact (SPDT—single pole double throw).

-

Load Switching: The closed contact connects the field device (e.g., motor starter) to the power source (480V AC), triggering the desired action.

-

Feedback: The module sends a status signal back to the DCS (via the backplane) indicating whether the relay is activated—critical for diagnostic purposes.

What sets the 1C31222G01 apart is its rugged design. The silver cadmium oxide contacts resist welding (even with inductive loads), and the module’s housing is made of flame-retardant polycarbonate (UL 94 V-0) to withstand harsh environments. It also supports hot-swapping, which means you can replace a faulty module without shutting down the process—essential for 24/7 operations like power plants.

Another key feature is compatibility. The 1C31222G01 works with all Ovation EMOD (Electronic Module) bases, so you can mix and match relay outputs with other I/O modules (e.g., analog inputs, digital inputs) in the same cabinet. This flexibility reduces inventory costs and simplifies maintenance—something we appreciate in the field, where time is money.

1C31222G01

Final Notes

The 1C31222G01 is a workhorse module for industrial automation. Its combination of high current capacity, galvanic isolation, and hot-swap capability makes it ideal for mission-critical applications where reliability is non-negotiable. Whether you’re upgrading a legacy system or building a new one, this module will handle the tough jobs—just remember to follow the installation tips to avoid common pitfalls.