Description

Key Technical Specifications

-

Model Number: 1B30035H01

-

Manufacturer: Emerson (formerly Westinghouse)

-

Slots: 2 standard I/O slots (compatible with Ovation EMOD/PMOD modules)

-

Mounting: DIN rail or panel mount (conforms to Ovation cabinet specifications)

-

Isolation: Galvanic isolation (channel-to-backplane) for noise immunity

-

Operating Temperature: –40°C to +70°C (IEC 60068-2 compliant)

-

Storage Temperature: –55°C to +85°C

-

Humidity Range: 0–95% RH (non-condensing)

-

Power Supply: Supplied via Ovation backplane (24V DC ±10%)

-

Dimensions: 106.7 mm × 129.5 mm × 25.4 mm (4.2 in × 5.1 in × 1.0 in)

-

Weight: ~0.3 kg (0.66 lbs)

-

Certifications: UL508, CE, ATEX II 3G Ex nA IIC T4 (hazardous location compliant)

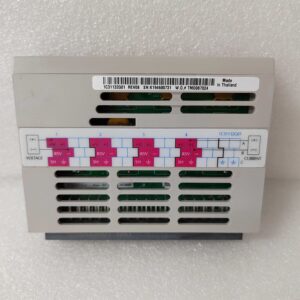

WESTINGHOUSE 1B30035H01

Field Application & Problem Solved

In industrial automation—from power plants to chemical refineries—control systems rely on I/O modules to connect field devices (e.g., temperature sensors, motor starters) to the DCS. The biggest challenge with legacy systems is finding a rugged, reliable base that securely mounts I/O modules while maintaining signal integrity in harsh environments. Cheap or poorly designed bases often fail due to vibration, temperature swings, or electrical noise—leading to intermittent faults or system downtime.

The 1B30035H01 solves this by providing a stable, isolated platform for Ovation I/O modules. You’ll find it in:

-

Power generation: Mounting analog input modules (e.g., 1C31224G01) for boiler temperature/pressure monitoring.

-

Chemical/petrochemical: Supporting digital output modules (e.g., 1C31223G01) for valve actuation.

-

Water treatment: Terminating analog output modules (e.g., 1C31129G03) for pump speed control.

Its core value is reliability in mission-critical applications. The galvanic isolation prevents field-induced noise (e.g., from nearby motors) from corrupting DCS signals—something we learned the hard way in a refinery where unisolated bases caused intermittent valve malfunctions. The 2-slot design also allows for flexible I/O expansion, reducing the need for additional cabinets.

Installation & Maintenance Pitfalls (Expert Tips)

1. Improper Mounting Torque

A common rookie mistake is over-tightening the DIN rail screws. The 1B30035H01’s housing is made of flame-retardant polycarbonate—over-tightening can crack the plastic, exposing internal components to dust and moisture. Always use a torque wrench to tighten screws to the manufacturer’s spec (typically 0.5–0.8 N·m). We once had a client crack a base during installation, leading to a week-long delay in a power plant’s maintenance shutdown.

2. Skipping Isolation Testing

Before installing I/O modules, verify channel-to-backplane isolation with a megger (insulation tester). The 1B30035H01’s isolation is rated for 1500V AC—if you get a lower reading, the base may be damaged. We once had a batch of bases with faulty isolation that caused ground loops in a chemical plant’s DCS.

3. Mixing Module Types

The 1B30035H01 is designed for Ovation EMOD/PMOD modules—don’t try to install third-party modules. Third-party modules may have different pinouts or power requirements, which can damage the base or the module. We’ve seen this happen in a paper mill where a non-Ovation module melted the base’s terminal block.

4. Neglecting Terminal Block Maintenance

Over time, terminal blocks can become corroded or loose—leading to intermittent connections. Inspect terminal blocks every 6 months for corrosion, and tighten screws if necessary. Use a small brush to clean corrosion with isopropyl alcohol. We once fixed a recurring valve fault in a power plant by replacing a corroded terminal block.

WESTINGHOUSE 1B30035H01

Technical Deep Dive & Overview

The 1B30035H01 is a passive I/O base module designed exclusively for Emerson’s Ovation Distributed Control System (DCS). It acts as a bridge between the DCS’s backplane (which carries power and data) and the field I/O modules (which interface with sensors and actuators). Here’s how it works:

-

Physical Mounting: The base is mounted to a DIN rail or panel using screws. Two I/O modules (e.g., analog input + digital output) are inserted into the slots.

-

Electrical Connection: The base’s terminal blocks connect to field wiring (e.g., 4-20mA signals from a temperature sensor). Internal traces carry power (24V DC) and data (digital signals) from the backplane to the modules.

-

Signal Isolation: Galvanic isolation (via optocouplers or transformers) separates the field wiring from the DCS backplane. This prevents voltage spikes or noise from the field from damaging the DCS.

-

Hot-Swap Capability: The base supports hot-swapping (replacing modules without shutting down the system). This is critical for 24/7 operations like power plants, where downtime is costly.

What sets the 1B30035H01 apart is its compatibility and ruggedness. It works with all Ovation EMOD/PMOD modules, so you can mix and match analog/digital I/O as needed. The polycarbonate housing is resistant to chemicals and moisture, making it ideal for harsh environments like refineries or paper mills.

Another key feature is simplicity. The base has no moving parts, so there’s less to break. Installation takes minutes—just mount the base, insert the modules, and connect the wiring. This simplicity reduces installation time and maintenance costs—something we appreciate in the field, where time is money.

Final Notes

The 1B30035H01 is a workhorse component for Ovation DCS systems. Its combination of ruggedness, compatibility, and simplicity makes it ideal for mission-critical applications where reliability is non-negotiable. Whether you’re upgrading a legacy system or building a new one, this base will provide a stable foundation for your I/O modules—just remember to follow the installation tips to avoid common pitfalls.