Description

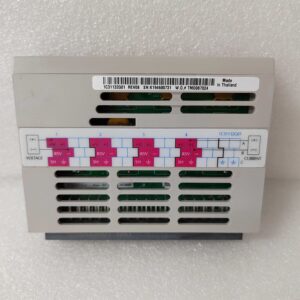

Product Overview

The Emerson Ovation 1C31150G01 is a high-precision pulse accumulator module designed exclusively for Emerson’s Ovation Distributed Control System (DCS). It serves as a critical component for pulse signal acquisition and processing in industrial automation applications, enabling accurate measurement of flow, speed, position, and other process variables. As part of the Ovation ecosystem, the 1C31150G01 is widely used in industries where reliable pulse counting is essential, such as power generation, chemical processing, water treatment, and manufacturing.

The 1C31150G01’s primary role is to count pulses from field devices (e.g., flow meters, encoders) and convert them into digital data for the Ovation controller. Its robust design (operating temperature range: –40°C to +70°C) and compatibility with Ovation DCS make it suitable for harsh industrial environments.

Key Technical Specifications

The 1C31150G01’s technical specifications are tailored for high-reliability pulse accumulation in industrial settings, with a focus on flexibility, precision, and compatibility:

-

Pulse Input Channels: 2 independent channels (supports simultaneous counting of two pulse signals).

-

Input Voltage Range: 24/48V DC or 5/12V DC (wide range for compatibility with varying field device outputs).

-

Counting Resolution: 32-bit (ensures accurate counting for high-volume applications, e.g., flow totalization).

-

Input Signal Type: Dry contact (NO/NC configurable) or open-collector transistor driver (low-true, referenced to common negative).

-

Time-Stamping: Millisecond-level precision (for SOE recording, critical for fault diagnosis).

-

Response Time: <10ms (typical, ensures real-time signal acquisition for critical control applications).

-

Power Supply: Powered via Ovation backplane (24V DC ±10% tolerance, typical for Ovation systems).

-

Power Consumption: <5W (low power design reduces heat dissipation in cabinets).

-

Operating Temperature: –40°C to +70°C (IEC 60068-2 compliant, suitable for extreme environments).

-

Storage Temperature: –40°C to +85°C (withstanding extreme storage conditions).

-

Humidity Range: 5–95% RH (non-condensing, resistant to moisture in humid environments).

-

Dimensions: ~150 mm × 80 mm × 30 mm (compact for cabinet installation).

-

Weight: ~0.3 kg (0.66 lbs, lightweight for easy handling during maintenance).

-

Certifications: CE, UL (compliant with international safety standards).

1C31150G01

Field Application & Problem Solved

In industrial automation, pulse accumulation is critical for:

-

Flow Measurement: Calculating fluid flow rates (e.g., water, gas) using flow meters that output pulse signals (e.g., turbine flow meters).

-

Speed Measurement: Monitoring the speed of rotating equipment (e.g., turbines, motors) using tachometers (pulse output proportional to speed).

-

Position Measurement: Determining the position of moving parts (e.g., conveyor belts, robotic arms) using encoders (pulse output proportional to displacement).

-

Production Counting: Tracking the number of products manufactured (e.g., bottles, cans) using production counters (pulse output per product).

The biggest challenge with legacy pulse accumulation systems is inaccurate counting (due to noise or poor signal conditioning) and limited compatibility (with only one pulse type). The 1C31150G01 solves this by:

-

Supporting Multiple Input Voltages: It accepts 24/48V DC or 5/12V DC pulse signals, eliminating the need for multiple modules.

-

Providing High Resolution: The 32-bit counter ensures accurate counting, even for high-volume applications (e.g., flow totalization in water treatment plants).

-

Enabling SOE Recording: Millisecond-level time-stamping allows for precise sequence of events logging, which is critical for fault diagnosis (e.g., identifying the root cause of a turbine trip).

Typical Applications:

-

Power Generation: Monitoring steam flow in boilers using turbine flow meters (pulse output proportional to flow rate).

-

Water Treatment: Tracking the flow of water through filtration systems using electromagnetic flow meters (pulse output).

-

Manufacturing: Counting the number of products produced on an assembly line using photoelectric counters (pulse output per product).

-

Chemical Processing: Monitoring the speed of agitators using tachometers (pulse output proportional to speed).

Installation & Maintenance Pitfalls (Expert Tips)

To ensure optimal performance and reliability, follow these best practices for installing and maintaining the 1C31150G01:

-

Verify Input Voltage Compatibility:

-

Always check the field device’s output voltage (24/48V DC or 5/12V DC) and configure the 1C31150G01 accordingly. Using an incompatible voltage can damage the module’s input circuitry.

-

Example: A client once burned out a module by connecting it to a 48V DC pulse signal without verifying compatibility—always use a multimeter to confirm the voltage before wiring.

-

-

Ensure Proper Wiring:

-

Use shielded twisted-pair cables for pulse connections to reduce electromagnetic interference (EMI). Avoid running cables alongside power lines—this is a classic cause of “ghost” pulse counts (false counts due to noise).

-

Tip: Ground the cable’s shield at one end (preferably the module end) to ensure effective shielding.

-

-

Configure Counting Modes:

-

Set the module’s counting mode (e.g., incremental, decremental) according to the field device’s specifications. For flow meters, use incremental counting (counts pulses as flow increases); for position sensors, use decremental counting (counts pulses as position decreases).

-

Common Mistake: Using the wrong counting mode can lead to inaccurate measurements—we fixed a recurring flow error in a water treatment plant by switching from decremental to incremental counting.

-

-

Perform Regular Diagnostics:

-

Use the Ovation software to monitor the module’s status (e.g., pulse count, input voltage, error codes) regularly. Address any faults (e.g., overfrequency, undervoltage) immediately to prevent downtime.

-

Case Study: A power plant avoided a boiler trip by detecting a faulty flow meter using the module’s diagnostic tools— the module flagged an “overfrequency” error, indicating that the flow meter was outputting too many pulses (a sign of blockage).

1C31150G01

-

Technical Deep Dive & Overview

The 1C31150G01 operates as part of the Ovation DCS architecture, which consists of:

-

Ovation Controller: Located in the central control room, it processes pulse data from the 1C31150G01 and sends commands to field devices.

-

1C31150G01 Module: Installed in a remote I/O node or control cabinet, it receives pulse signals from field devices.

-

Field Devices: Flow meters, encoders, tachometers, and production counters connected to the 1C31150G01.

How It Works:

-

Signal Reception: The 1C31150G01 receives pulse signals (e.g., from a flow meter) via its input terminals.

-

Signal Conditioning: The module filters out noise (via a low-pass filter) and amplifies the signal to ensure accurate counting.

-

Pulse Counting: The conditioned signal is sent to a 32-bit counter, which increments for each pulse received.

-

Time-Stamping: A built-in real-time clock (RTC) assigns a millisecond-level timestamp to each pulse (e.g., “pulse received at 10:00:00.123”).

-

Data Transmission: The module sends the pulse count data (and timestamps) to the Ovation controller via the Ovation network.

-

Process Control: The Ovation controller uses the pulse count data to adjust field devices (e.g., opening a valve to increase flow) or trigger alarms (e.g., a flow meter failure).

Key Advantages:

-

Compatibility: Works with all Ovation DCS controllers and field devices (e.g., flow meters from Siemens, Rosemount).

-

Ruggedness: The module’s housing is made of flame-retardant polycarbonate (UL 94 V-0) to withstand harsh environments (e.g., high temperatures in power plants).

-

Ease of Use: The module’s configuration options (input voltage, counting mode) simplify installation and maintenance—critical for 24/7 operations.

Final Notes

The Emerson Ovation 1C31150G01 is a reliable and essential component of the Ovation DCS, enabling precise pulse accumulation for industrial automation. Its compatibility with multiple input voltages, high resolution, and millisecond-level time-stamping make it ideal for mission-critical applications where pulse counting is non-negotiable. Whether you’re upgrading a legacy system or building a new one, the 1C31150G01 will provide the accurate pulse data you need—just remember to follow the installation tips to avoid common pitfalls.