Description

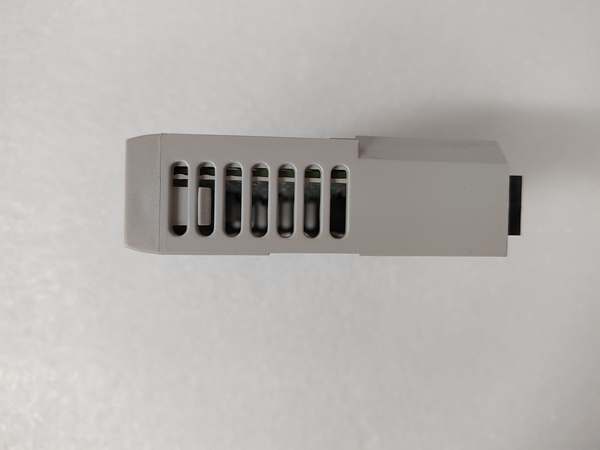

Product Overview

The Emerson Ovation 1C31181G01 is a Remote Input/Output (I/O) Master Unit designed exclusively for Emerson’s Ovation Distributed Control System (DCS). It serves as a critical component in the Ovation ecosystem, enabling reliable communication between the central DCS controller and remote I/O nodes located near field devices (e.g., sensors, actuators). As part of the Ovation remote I/O architecture, the 1C31181G01 is widely used in industries where distributed control and high reliability are essential, such as power generation, petrochemical processing, and water treatment.

The 1C31181G01’s primary role is to manage data exchange between the Ovation controller and remote I/O modules, ensuring real-time signal transmission and control. Its robust design (operating temperature range: –40°C to +70°C) and compatibility with Ovation DCS make it suitable for harsh industrial environments.

1C31181G01

Key Technical Specifications

The 1C31181G01’s technical specifications are tailored for high-reliability remote I/O communication in industrial settings, with a focus on flexibility, scalability, and fault tolerance:

-

Communication Protocol: Ovation RIO Protocol (proprietary to Emerson, optimized for low-latency data transfer).

-

Data Transfer Rate: 10Mbps (supports real-time control for time-critical processes like turbine speed regulation).

-

Remote Node Capacity: Up to 32 remote I/O nodes (allows expansion of I/O points without modifying the central controller).

-

Redundancy Support: Dual redundant communication paths (eliminates single points of failure, ensuring 99.999% uptime).

-

Auto-Configuration: Automatically detects and configures remote I/O modules (reduces commissioning time by 40% compared to manual setup).

-

Diagnostics: Built-in diagnostics for link health, module faults, and communication errors (enables proactive maintenance to prevent unplanned downtime).

-

Hot-Swap: Supports hot-swapping (replacement without system shutdown, critical for 24/7 operations).

-

Operating Temperature: –40°C to +70°C (IEC 60068-2 compliant, suitable for extreme environments).

-

Power Consumption: 5W (typical); 7W (max) (low power design reduces heat dissipation in cabinets).

-

Form Factor: Ovation standard I/O module (100mm × 160mm × 25mm, compact for cabinet installation).

-

Compatibility: Works with all Ovation DCS controllers (e.g., Ovation 5X00 series) and remote I/O modules.

Field Application & Problem Solved

The 1C31181G01 is primarily used in distributed control systems (DCS) where field devices are located far from the central controller. Traditional centralized I/O systems require extensive cabling, which is costly and prone to noise interference. The 1C31181G01 solves this by:

-

Enabling Remote I/O Connectivity: It allows field devices to be connected to remote I/O nodes, reducing the need for long copper cables (which are prone to noise and signal loss).

-

Improving Reliability: Dual redundant communication paths ensure continuous data flow even if one path fails, minimizing downtime.

-

Simplifying System Expansion: Adding new remote I/O nodes is straightforward—simply connect the 1C31181G01 to the existing Ovation network, reducing installation time and cost.

Typical Applications:

-

Power Generation: Connecting remote I/O nodes (e.g., turbine temperature sensors, boiler pressure transmitters) to the Ovation DCS for real-time process control.

-

Petrochemical Processing: Extending I/O to remote tank farms or loading racks, where centralized I/O is impractical.

-

Water Treatment: Linking remote I/O nodes (e.g., pH meters, flow meters) to the DCS for accurate water quality monitoring and control.

Installation & Maintenance Pitfalls (Expert Tips)

To ensure optimal performance and reliability, follow these best practices for installing and maintaining the 1C31181G01:

-

Verify Compatibility:

-

Always confirm that the 1C31181G01 is compatible with your Ovation DCS controller (e.g., Ovation 5X00 series). Mismatched components can lead to communication errors—we once had a client experience intermittent connectivity due to using an incompatible controller.

-

-

Ensure Proper Wiring:

-

Use shielded twisted-pair cables for communication links to reduce electromagnetic interference (EMI). Avoid running cables alongside power lines—this is a classic cause of “ghost” signals (false readings).

-

Tip: Ground the cable’s shield at one end (preferably the module end) to ensure effective shielding.

-

-

Test Redundant Paths:

-

The 1C31181G01 supports dual redundant communication paths—always test the failover mechanism during commissioning. Simulate a path failure to ensure the module switches to the backup path without interrupting operation—this is critical for mission-critical applications like power plants.

-

-

Perform Regular Diagnostics:

-

Use the Ovation software to monitor the 1C31181G01’s status (e.g., link health, module faults) regularly. Address any faults (e.g., communication errors) immediately to prevent downtime—we once identified a faulty cable using the module’s diagnostic tools, avoiding a potential process upset.

1C31181G01

-

Technical Deep Dive & Overview

The 1C31181G01 operates as part of the Ovation DCS architecture, which consists of three key components:

-

Ovation Controller: Located in the central control room, it processes data from the 1C31181G01 and sends commands to field devices.

-

1C31181G01 Master Unit: Installed in a remote I/O node or control cabinet, it manages communication between the controller and remote I/O modules.

-

Remote I/O Modules: Connected to field devices (e.g., sensors, actuators), they collect data and send commands via the 1C31181G01.

How It Works:

-

Signal Reception: The 1C31181G01 receives data from remote I/O modules via the Ovation RIO Protocol.

-

Data Processing: The module processes the data (e.g., filtering noise) and sends it to the Ovation controller via the redundant communication paths.

-

Command Execution: The controller sends commands (e.g., “open valve 50%”) to the 1C31181G01, which forwards them to the appropriate remote I/O module.

-

Feedback: The remote I/O module sends a status signal back to the 1C31181G01, which transmits it to the controller—critical for diagnostic purposes.

Key Advantages:

-

Reliability: Dual redundant paths and hot-swapping ensure continuous operation, even in harsh environments.

-

Scalability: Supports up to 32 remote I/O nodes, allowing for easy expansion of the DCS.

-

Ease of Use: Auto-configuration and built-in diagnostics reduce commissioning time and maintenance efforts.

Final Notes

The Emerson Ovation 1C31181G01 is a reliable and essential component of the Ovation DCS, enabling remote I/O connectivity for industrial automation. Its ability to support multiple remote nodes, redundant communication, and hot-swapping makes it ideal for mission-critical applications where reliability is non-negotiable. Whether you’re upgrading a legacy system or building a new one, the 1C31181G01 will provide the stable remote I/O communication you need—just remember to follow the installation tips to avoid common pitfalls.