Description

Product Overview

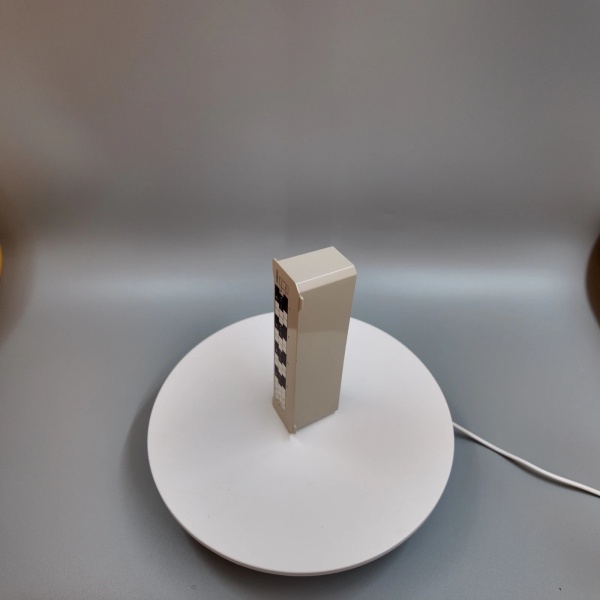

The Emerson Ovation 1X00188H01 is a HART-compatible analog input module designed exclusively for Emerson’s Ovation Distributed Control System (DCS). It serves as a critical interface for acquiring analog signals from HART-enabled field devices (e.g., pressure transmitters, temperature sensors) and converting them into digital data for the Ovation controller. As part of the Ovation ecosystem, the 1X00188H01 is widely used in industries where high-precision process control and smart device communication are essential, such as power generation, chemical processing, and water treatment.

The 1X00188H01’s primary role is to enable accurate measurement of process variables (e.g., pressure, temperature) while supporting HART communication for device diagnostics. Its 16-bit resolution and ±0.1% accuracy ensure reliable data for process optimization, while HART support allows for predictive maintenance—reading diagnostic data from smart devices without interrupting the process.

WESTINGHOUSE 1X00188H01

Key Technical Specifications

The 1X00188H01’s technical specifications are tailored for high-reliability analog signal acquisition in industrial environments, with a focus on precision, flexibility, and compatibility:

-

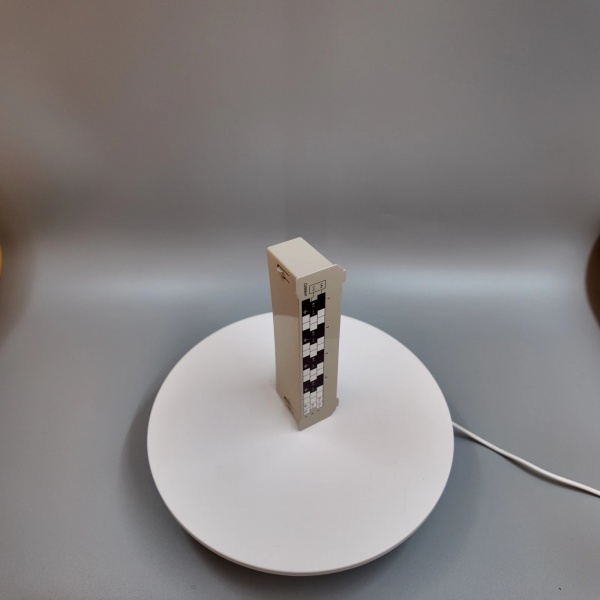

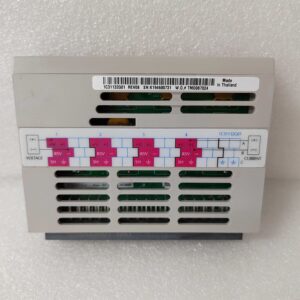

Input Channels: 4 independent analog input channels (configurable for 4-20mA current or 1-5V voltage signals).

-

Input Signal Types: 4-20mA DC (current loop), 1-5V DC (voltage) (compatible with most HART-enabled field devices).

-

Resolution: 16-bit A/D conversion (ensures accurate signal conversion for precise measurements).

-

Accuracy: ±0.1% of span (typical at 25°C ambient, critical for maintaining process stability).

-

HART Compatibility: Supports HART 5.x and 7.x protocols (enables bidirectional communication with smart field devices).

-

Isolation: Channel-to-channel isolation (1500 Vac), channel-to-ground isolation (500 Vac) (prevents cross-talk and surge damage from field devices).

-

Power Consumption: 5W maximum (low power design reduces heat dissipation in cabinets).

-

Operating Temperature: 0°C to 60°C (32°F to 140°F), suitable for most industrial environments.

-

Dimensions: ~222 mm × 140 mm × 64 mm (8.75 in × 5.5 in × 2.5 in, compact for cabinet installation).

-

Weight: ~0.3 kg (0.66 lbs, lightweight for easy handling).

Field Application & Problem Solved

In industrial automation—from power plants to chemical refineries—analog signal acquisition is critical for monitoring process variables like pressure, temperature, and flow. The biggest challenge with legacy analog input modules is finding a solution that balances high precision (for accurate control) with intelligence (for predictive maintenance). Solid-state modules often fall short: they lack the resolution for fine-tuned adjustments, and their inability to communicate with smart devices limits diagnostic capabilities.

The 1X00188H01 solves this by combining 16-bit resolution (for precise signal conversion) with HART protocol support (for smart device communication). Here are its key applications:

-

Power Generation: Monitoring boiler feedwater pressure (via HART-enabled pressure transmitters) and turbine inlet temperature (via HART-enabled temperature sensors). The 16-bit resolution allows for incremental adjustments (e.g., 0.01% of full scale), which is essential for maintaining optimal turbine efficiency.

-

Chemical Processing: Tracking distillation column temperature (via HART-enabled thermocouples) and reactor pressure (via HART-enabled pressure transmitters). HART support enables predictive maintenance—you can read diagnostic data from smart sensors (e.g., sensor drift, calibration status) without interrupting the process, reducing downtime and repair costs.

-

Water Treatment: Measuring pipeline flow (via HART-enabled flow meters) and pH levels (via HART-enabled pH sensors). The module’s high accuracy ensures consistent water quality, while HART communication allows for real-time monitoring of sensor health.

Its core value is precision and intelligence in mission-critical applications. The 16-bit resolution ensures that the input signal is accurate to within 0.01% of full scale, which is essential for processes like chemical blending where small changes can affect product quality. The HART support also allows you to detect issues like sensor drift before they cause a process upset, enabling proactive maintenance.

Installation & Maintenance Pitfalls (Expert Tips)

To ensure optimal performance and reliability, follow these best practices for installing and maintaining the 1X00188H01:

-

Incorrect Wiring of Current LoopsA common mistake is reversing the polarity of the 4-20mA current loop. Always connect the positive terminal (+) of the module to the positive terminal of the field device (e.g., pressure transmitter) and the negative terminal (–) to the negative terminal. Reversing polarity will cause the device to misinterpret the signal—we once had a client burn out a transmitter because of this error.

-

Ignoring HART ConfigurationThe 1X00188H01 supports HART, but you must enable it in the Ovation software. If HART is disabled, you won’t be able to read diagnostic data from smart devices. To enable HART, go to the module’s configuration page in Ovation Explorer and check the “Enable HART” box. We’ve seen technicians skip this step, leading to missed opportunities for predictive maintenance.

-

Poor Shielding of Field CablesAnalog signals are susceptible to electromagnetic interference (EMI) from nearby power cables or motors. Always use shielded twisted-pair cables for field wiring, and ground the shield at one end (preferably the module end). Un-shielded cables can pick up noise, causing the input signal to fluctuate—we fixed a recurring pressure reading error in a refinery by replacing un-shielded cables with shielded ones.

-

Skipping Calibration ChecksEven though the 1X00188H01 has high accuracy, it’s important to calibrate it annually using a precision multimeter. Check the input signal (4-20mA) against the module’s display in Ovation Explorer. If the signal deviates by more than ±0.1%, recalibrate the module using Emerson’s calibration tool. We once found a module with a 0.2% error that was causing a 5% variation in product quality—calibration fixed the issue.

WESTINGHOUSE 1X00188H01

Technical Deep Dive & Overview

The 1X00188H01 is a HART-compatible analog input module designed exclusively for Emerson’s Ovation DCS. It acts as a bridge between the DCS’s digital control signals and the analog signals from field devices. Here’s how it works:

-

Signal Reception: The module receives analog signals from field devices (e.g., 4-20mA from a pressure transmitter) via 4 input channels.

-

Signal Conditioning: The module’s internal circuitry filters out noise (via a low-pass filter) and amplifies the signal (if necessary) to ensure accurate conversion.

-

Isolation: Galvanic isolation (via optocouplers) separates the field wiring from the DCS backplane, preventing surge damage and cross-talk.

-

Analog-to-Digital Conversion (ADC): The module’s 16-bit ADC converts the conditioned analog signal to a digital value (e.g., 0–65535 counts) proportional to the process variable.

-

HART Communication: If the field device is HART-enabled, the module transmits diagnostic data (e.g., transmitter status, calibration date) back to the DCS via the same current loop.

-

Data Transmission: The digital value is sent to the Ovation controller via the backplane, where it’s used for process control (e.g., adjusting a valve position).

What sets the 1X00188H01 apart is its combination of precision and intelligence. The 16-bit ADC ensures that the input signal is accurate to within 0.01% of full scale, which is essential for processes like chemical blending where small changes can affect product quality. The HART support also allows you to monitor the health of field devices—for example, you can detect a drifting sensor before it causes a process upset.

Another key feature is hot-swapping. The module can be replaced without shutting down the system, which is critical for 24/7 operations like power plants. The galvanic isolation also prevents field-induced noise (e.g., from nearby motors) from corrupting the DCS signals—something we learned the hard way in a paper mill where unisolated inputs caused intermittent valve malfunctions.

Final Notes

The Emerson Ovation 1X00188H01 is a reliable and essential component of the Ovation DCS, enabling high-precision analog input for industrial automation. Its compatibility with HART-enabled devices, high resolution, and robust design make it ideal for mission-critical applications where reliability is non-negotiable. Whether you’re upgrading a legacy system or building a new one, the 1X00188H01 will provide the accurate, reliable analog input you need—just remember to follow the installation tips to avoid common pitfalls.