Description

Key Technical Specifications

-

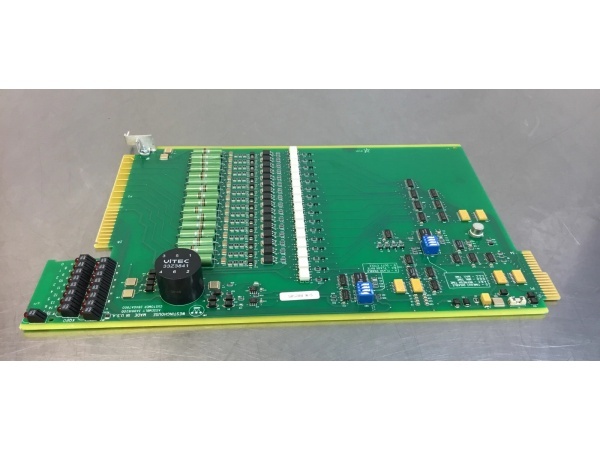

Model Number: 3A99162G01

-

Manufacturer: Emerson (formerly Westinghouse)

-

Number of Channels: 16 independent digital output channels

-

Output Rating: 60VDC maximum voltage, 300mA maximum current per channel (resistive load)

-

Output Type: Transistor-transistor logic (TTL) compatible (check Emerson documentation for exact logic levels)

-

Isolation: Galvanic isolation (channel-to-logic) for noise immunity (typical for Ovation I/O modules)

-

Operating Temperature: –40°C to +70°C (IEC 60068-2 compliant, suitable for harsh industrial environments)

-

Storage Temperature: –55°C to +85°C

-

Humidity Range: 0–95% RH (non-condensing)

-

Power Supply: Supplied via Ovation backplane (24V DC ±10% tolerance, typical for Ovation systems)

-

Power Consumption: <1W per module (low power consumption for reduced heat dissipation)

-

Mounting: DIN rail or panel mount (compatible with Ovation EMOD/PMOD bases)

-

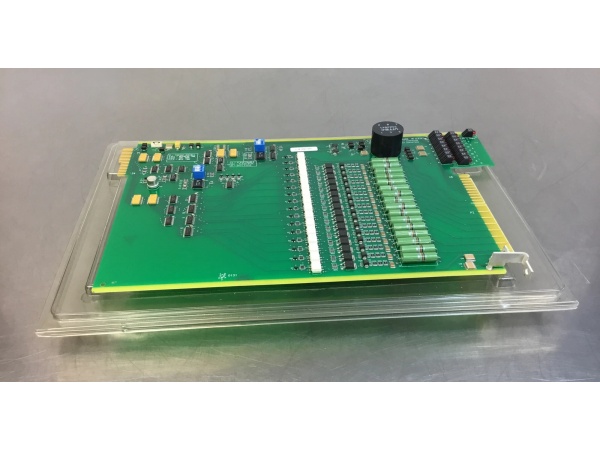

Dimensions: ~144 mm × 60 mm × 30 mm (5.67 in × 2.36 in × 1.18 in, typical for Ovation 16-channel modules)

-

Weight: ~300 g (0.66 lbs, lightweight for easy installation)

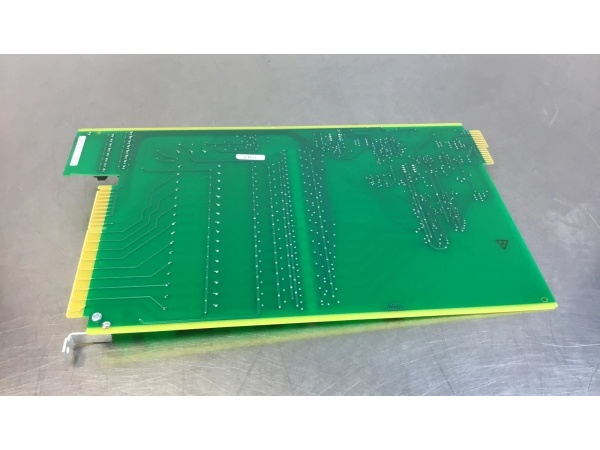

WESTINGHOUSE 3A99162G01

Field Application & Problem Solved

In industrial automation—from power plants to chemical refineries—control systems rely on digital output signals to trigger field devices like solenoid valves, motor contactors, and alarm relays. The biggest challenge with legacy systems is finding a digital output module that balances high channel density (to minimize cabinet space) with reliable current delivery (to drive multiple field devices). Solid-state modules often fall short: they lack the current capacity for multiple loads, and their susceptibility to noise can corrupt signals—leading to intermittent device malfunctions.

The 3A99162G01 solves this by providing 16 isolated digital output channels (each capable of 300mA) in a compact form factor. You’ll find it in:

-

Power generation: Controlling boiler feedwater solenoid valves, turbine lube oil system relays, and generator breaker controls.

-

Chemical/petrochemical: Actuating process solenoid valves (e.g., in distillation columns) and starting motor contactors for pumps/compressors.

-

Manufacturing: Driving conveyor belt solenoids, robotic arm relays, and assembly line actuators.

Its core value is space efficiency and reliability in mission-critical applications. The 16-channel design reduces the number of modules needed (and thus cabinet space), while the 300mA per channel rating allows driving multiple low-current devices (e.g., two 150mA solenoids) from a single channel. The galvanic isolation also prevents field-induced noise (e.g., from nearby motors) from corrupting DCS signals—something we learned the hard way in a refinery where unisolated outputs caused intermittent valve trips.

Installation & Maintenance Pitfalls (Expert Tips)

1. Overloading Channels with Inductive Loads

A common rookie mistake is connecting multiple inductive loads (e.g., solenoids, relays) to a single channel without checking the total current. Inductive loads draw higher current at startup (inrush current), which can exceed the 300mA limit and damage the module. Always calculate the total inrush current for all devices on a channel—if it exceeds 300mA, use a separate channel or add an external relay. We once had a client burn out a channel by connecting three 150mA solenoids (total inrush: 450mA)—the module’s output transistor failed, causing a 4-hour downtime in a power plant.

2. Ignoring Isolation Requirements

The 3A99162G01 has galvanic isolation between channels and the logic circuit, but you must still ground the module’s shield properly. If the shield is not grounded, electromagnetic interference (EMI) from nearby power cables can induce noise into the output signals—leading to “false” triggers (e.g., a solenoid activating without a command). Always ground the shield to the cabinet’s earth ground using a dedicated ground wire. We fixed a recurring valve malfunction in a paper mill by adding a ground wire to the module’s shield.

3. Poor Wiring Practices

Use twisted-pair cables for field wiring to reduce EMI. Avoid running output wires alongside power cables—this is a classic cause of cross-talk (noise from power cables interfering with output signals). Also, label each terminal clearly: nothing wastes more time than tracing a wire in a crowded cabinet only to find it’s connected to the wrong channel. We once spent 2 hours troubleshooting a faulty output—only to find the wire was connected to channel 5 instead of channel 10.

4. Forgetting Hot-Swap Capability

The 3A99162G01 supports hot-swapping (replacing modules without shutting down the system), but you must follow the correct procedure:

-

Remove the module from the base.

-

Wait 5 seconds (to allow the backplane to discharge).

-

Insert the new module.If you skip the 5-second wait, you risk damaging the backplane’s connector pins. We had a junior engineer yank a module out mid-operation—this fried the backplane connector, requiring a $500 repair and 8 hours of downtime.

WESTINGHOUSE 3A99162G01

Technical Deep Dive & Overview

The 3A99162G01 is a 16-channel digital output card designed exclusively for Emerson’s Ovation Distributed Control System (DCS). It acts as a bridge between the DCS’s low-voltage digital signals (24V DC) and the higher-voltage/current requirements of field devices. Here’s how it works:

-

Signal Reception: The Ovation controller sends a digital command (e.g., “open valve”) to the 3A99162G01 via the backplane.

-

Logic Processing: The module’s internal circuitry validates the command (checks for valid logic levels, overcurrent conditions).

-

Output Switching: If the command is valid, the module energizes the corresponding output transistor (TTL compatible), connecting the field device (e.g., solenoid) to the power source (24V DC).

-

Feedback: The module sends a status signal back to the DCS (via the backplane) indicating whether the output is active—critical for diagnostic purposes (e.g., detecting a faulty solenoid).

What sets the 3A99162G01 apart is its rugged design and compatibility. The module’s housing is made of flame-retardant polycarbonate (UL 94 V-0) to withstand harsh environments (e.g., high temperatures in power plants). It also works with all Ovation EMOD/PMOD bases, so you can mix and match digital outputs with other I/O modules (e.g., analog inputs, digital inputs) in the same cabinet—reducing inventory costs and simplifying maintenance.

Another key feature is low power consumption. The module draws less than 1W of power, which reduces heat dissipation in the cabinet—critical for 24/7 operations like power plants, where overheating can cause module failures. The 16-channel design also minimizes the number of modules needed, saving valuable cabinet space.

Final Notes

The 3A99162G01 is a workhorse module for industrial automation. Its combination of 16 isolated channels, 300mA current rating, and rugged design makes it ideal for mission-critical applications where reliability is non-negotiable. Whether you’re upgrading a legacy system or building a new one, this module will handle the tough jobs—just remember to follow the installation tips to avoid common pitfalls.