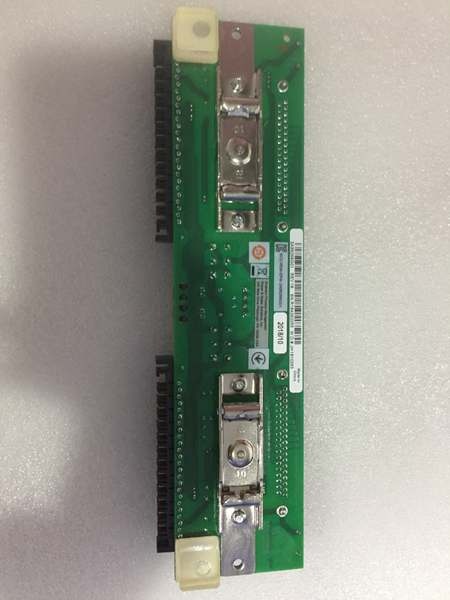

Description

Key Technical Specifications

-

Model Number: 3A99266G01

-

Manufacturer: Emerson (formerly Westinghouse)

-

Number of Channels: 16 independent analog input channels

-

Input Voltage Range: ±10 VDC (nominal)

-

Input Current Range: 4–20 mA (compatible with most industrial sensors)

-

Power Supply: 24 VDC (±10% tolerance) via Ovation backplane

-

Power Consumption: 20 W (max) – low power design for centralized cabinets

-

Isolation: Channel-to-channel (500 V AC) and channel-to-backplane (1000 V AC) isolation for noise immunity

-

Operating Temperature: –40°C to +70°C (IEC 60068-2 compliant) – suitable for harsh industrial environments

-

Storage Temperature: –40°C to +85°C

-

Humidity Range: 0–95% RH (non-condensing)

-

Vibration Resistance: 5g RMS (10–500 Hz) – withstands vibration from nearby machinery

-

Shock Resistance: 30g (11 ms half-sine) – survives impacts during shipping or installation

-

Dimensions: ~452 mm × 279 mm × 110 mm (17.8 in × 11 in × 4.3 in) – compact for cabinet installation

-

Weight: ~1 kg (2.2 lbs) – lightweight for easy handling

-

Certifications: CE, UL, CSA (compliant with international safety standards)

3A99266G01

Field Application & Problem Solved

In industrial automation—from power plants to chemical refineries—field devices (e.g., temperature sensors, pressure transmitters, control valves) rely on stable signal transmission to the DCS for process control. The biggest challenge with legacy I/O systems is finding a rugged, reliable transition panel that can withstand harsh environments (e.g., high temperatures, vibration, electromagnetic interference) while maintaining signal integrity. Cheap or poorly designed panels often fail due to poor isolation, leading to noise-induced signal corruption or equipment damage.

The 3A99266G01 solves this by providing 16 isolated analog input channels in a compact, rugged form factor. You’ll find it in:

-

Power generation: Connecting boiler temperature sensors, turbine pressure transmitters, and generator vibration monitors to the Ovation DCS.

-

Chemical/petrochemical: Interfacing with reactor temperature sensors, distillation column pressure transmitters, and valve positioners.

-

Manufacturing: Linking conveyor belt speed sensors, robotic arm position transmitters, and assembly line actuators.

Its core value is reliability in mission-critical applications. The channel isolation (500 V AC) prevents cross-talk and surge damage, ensuring stable operation in high-EMI environments like power plants. The hot-swap capability allows maintenance without system shutdown—critical for 24/7 operations where downtime is costly.

Installation & Maintenance Pitfalls (Expert Tips)

1. Ignoring Isolation Requirements

A common rookie mistake is assuming all I/O panels have adequate isolation. The 3A99266G01’s isolation is rated for 500 V AC—always verify this with a megger (insulation tester) before installation. We once had a client skip this step, and a surge from a nearby motor damaged the panel’s input channels, causing a 4-hour downtime in a power plant.

2. Incorrect Wiring of Analog Inputs

Analog inputs (e.g., from sensors) require proper wiring to avoid signal degradation. Always use shielded twisted-pair cables for field wiring, and ground the shield at one end (preferably the panel end). Un-shielded cables can pick up EMI, leading to inaccurate readings—we fixed a recurring temperature discrepancy in a refinery by replacing un-shielded cables with shielded ones.

3. Overlooking Hot-Swap Procedure

The 3A99266G01 supports hot-swapping, but you must follow the correct procedure:

-

Remove the panel from the chassis.

-

Wait 5 seconds (to allow the backplane to discharge).

-

Insert the new panel.If you skip the 5-second wait, you risk damaging the backplane’s connector pins. We had a junior engineer yank a panel out mid-operation—this fried the backplane connector, requiring a $500 repair and 8 hours of downtime.

4. Poor Grounding

Grounding is critical for noise immunity. Always ground the panel’s chassis to the cabinet’s earth ground using a dedicated ground wire. Poor grounding can lead to intermittent signal loss—we fixed a recurring valve malfunction in a paper mill by adding a ground wire to the panel’s chassis.

3A99266G01

Technical Deep Dive & Overview

The 3A99266G01 is a local input/output transition panel designed exclusively for Emerson’s Ovation Distributed Control System (DCS). It acts as a bridge between the DCS’s backplane (which carries power and data) and the field devices (which provide analog signals). Here’s how it works:

-

Signal Reception: The panel receives analog signals (e.g., 4–20 mA from a temperature sensor) via 16 input channels.

-

Signal Conditioning: The panel’s internal circuitry filters out noise (via a low-pass filter) and amplifies the signal (if necessary) to ensure accurate transmission.

-

Isolation: Galvanic isolation (via optocouplers) separates the field wiring from the DCS backplane, preventing surge damage and cross-talk.

-

Digital Conversion: The panel converts the conditioned analog signal to a digital value (via an A/D converter) and sends it to the Ovation controller via the backplane.

-

Status Indication: Front-panel LEDs provide real-time feedback for each channel (e.g., “ON” for active signals, “FAULT” for errors), aiding in troubleshooting.

What sets the 3A99266G01 apart is its rugged design and compatibility. The panel’s stainless steel housing resists corrosion and impact, making it ideal for harsh environments like refineries or paper mills. It also works seamlessly with all Ovation I/O modules (e.g., digital inputs, analog outputs), so you can mix and match I/O types in the same cabinet—reducing inventory costs and simplifying maintenance.

Another key feature is redundant power support. The panel can be powered by two separate 24 VDC sources, ensuring continuous operation even if one power supply fails. This is critical for 24/7 operations like power plants, where downtime is not an option.

Final Notes

The 3A99266G01 is a workhorse panel for industrial automation. Its combination of 16 isolated channels, rugged design, and Ovation compatibility makes it ideal for mission-critical applications where reliability is non-negotiable. Whether you’re upgrading a legacy system or building a new one, this panel will provide the stable signal transmission you need—just remember to follow the installation tips to avoid common pitfalls.