Description

Product Overview

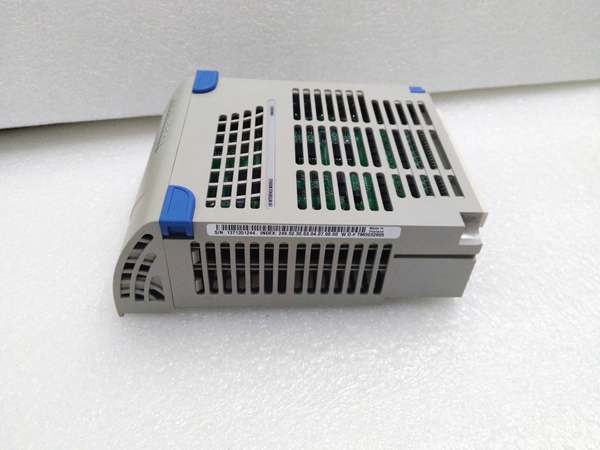

The Emerson Ovation 5X00226G02 is a high-reliability I/O interface module designed exclusively for Emerson’s Ovation Distributed Control System (DCS). It serves as the critical communication backbone between Ovation controllers (e.g., OCR1100) and distributed I/O networks, enabling seamless data exchange in industrial automation applications. As part of the Ovation ecosystem, the 5X00226G02 is widely used in industries where mission-critical process control is essential, such as power generation, chemical processing, and water treatment.

The 5X00226G02’s primary role is to translate controller logic into fieldbus protocols compatible with remote I/O racks, managing cyclic data updates, alarm propagation, and module health monitoring. Its robust design (operating temperature range: –40°C to +70°C) and support for dual-redundant configurations make it suitable for harsh industrial environments, ensuring uninterrupted operation even in critical process loops.

WESTINGHOUSE 5X00226G02

Key Technical Specifications

The 5X00226G02’s technical specifications are tailored for high-reliability communication in industrial settings, with a focus on fault tolerance, scalability, and compatibility:

-

Protocol Support: Proprietary Ovation I/O bus (optimized for deterministic scan times and low latency).

-

Data Throughput: Handles hundreds of I/O points per module with sub-10ms latency (ensures real-time control for time-critical processes like turbine speed regulation).

-

Redundancy: Supports hot-standby pairing for seamless failover (requires dual modules), eliminating single points of failure in critical applications.

-

Environmental Ratings: Operates in temperatures from –40°C to +70°C; conformal coating protects against moisture and dust (suitable for harsh environments like power plants).

-

Compatibility: Works with all Ovation DCS controllers (e.g., OCR1100) and remote I/O modules; backward-compatible with legacy Ovation systems.

Field Application & Problem Solved

In industrial automation, distributed I/O architecture is essential for connecting centralized controllers to field devices (e.g., sensors, actuators) located near industrial equipment. The biggest challenge with legacy I/O systems is communication latency (causing delayed control actions) and lack of fault tolerance (leading to downtime). The 5X00226G02 solves this by:

-

Enabling Real-Time Communication: The module’s sub-10ms latency ensures that control commands (e.g., “open valve 50%”) are executed promptly, which is critical for processes like turbine speed regulation or chemical reactor temperature control.

-

Providing Fault Tolerance: Dual-redundant configurations ensure continuous data flow even if one module fails, minimizing downtime in mission-critical applications like power generation.

-

Simplifying System Expansion: Adding new remote I/O racks is straightforward—simply install additional 5X00226G02 modules and connect them to the existing Ovation network, reducing installation time and cost.

Typical Applications:

-

Power Generation: Connecting Ovation controllers to remote I/O racks (e.g., turbine temperature sensors, boiler pressure transmitters) for real-time process control.

-

Chemical Processing: Linking Ovation DCS to field devices (e.g., flow meters, pressure transmitters) for accurate process monitoring and control.

-

Water Treatment: Integrating Ovation DCS with pump actuators and sensor networks for efficient water quality management.

Installation & Maintenance Pitfalls (Expert Tips)

To ensure optimal performance and reliability, follow these best practices for installing and maintaining the 5X00226G02:

-

Verify Compatibility:

-

Always confirm that the 5X00226G02 is compatible with your Ovation DCS controller (e.g., OCR1100). Mismatched components can lead to communication errors—we once had a client experience intermittent connectivity due to using an incompatible controller.

-

-

Test Redundant Configurations:

-

The 5X00226G02 supports dual-redundant configurations—always test the failover mechanism during commissioning. Simulate a module failure to ensure the backup module takes over without interrupting operation—this is critical for mission-critical applications like power plants.

-

-

Ensure Proper Wiring:

-

Use shielded twisted-pair cables for communication links to reduce electromagnetic interference (EMI). Avoid running cables alongside power lines—this is a classic cause of “ghost” signals (false readings).

-

Tip: Ground the cable’s shield at one end (preferably the module end) to ensure effective shielding.

-

-

Perform Regular Diagnostics:

-

Use the Ovation software to monitor the 5X00226G02’s status (e.g., link health, module faults) regularly. Address any faults (e.g., communication errors) immediately to prevent downtime—we once identified a faulty cable using the module’s diagnostic tools, avoiding a potential process upset.

WESTINGHOUSE 5X00226G02

-

Technical Deep Dive & Overview

The 5X00226G02 operates as part of the Ovation DCS architecture, which consists of three key components:

-

Ovation Controller: Located in the central control room, it processes data from the 5X00226G02 and sends commands to field devices.

-

5X00226G02 Interface Module: Installed in the controller chassis, it translates controller logic into fieldbus protocols compatible with remote I/O racks.

-

Remote I/O Racks: Located near field devices, they collect data from sensors and actuators and send commands via the 5X00226G02.

How It Works:

-

Signal Reception: The 5X00226G02 receives data from remote I/O racks via the proprietary Ovation I/O bus.

-

Data Processing: The module processes the data (e.g., filtering noise) and sends it to the Ovation controller via the redundant communication paths.

-

Command Execution: The controller sends commands (e.g., “open valve 50%”) to the 5X00226G02, which forwards them to the appropriate remote I/O rack.

-

Feedback: The remote I/O rack sends a status signal back to the 5X00226G02, which transmits it to the controller—critical for diagnostic purposes.

Key Advantages:

-

Reliability: Dual-redundant configurations and hot-standby pairing ensure continuous operation, even in harsh environments.

-

Scalability: Supports mixed analog, digital, and specialty I/O types on the same network segment, allowing for easy system expansion.

-

Ease of Use: Auto-discovery of I/O modules reduces configuration time in Ovation Developer Studio, simplifying engineering efforts.

Final Notes

The Emerson Ovation 5X00226G02 is a reliable and essential component of the Ovation DCS, enabling high-speed communication between controllers and distributed I/O networks. Its fault-tolerant design, real-time performance, and compatibility with Ovation ecosystems make it ideal for mission-critical applications where reliability is non-negotiable. Whether you’re upgrading a legacy system or building a new one, the 5X00226G02 will provide the stable communication backbone you need—just remember to follow the installation tips to avoid common pitfalls.