Description

Product Overview

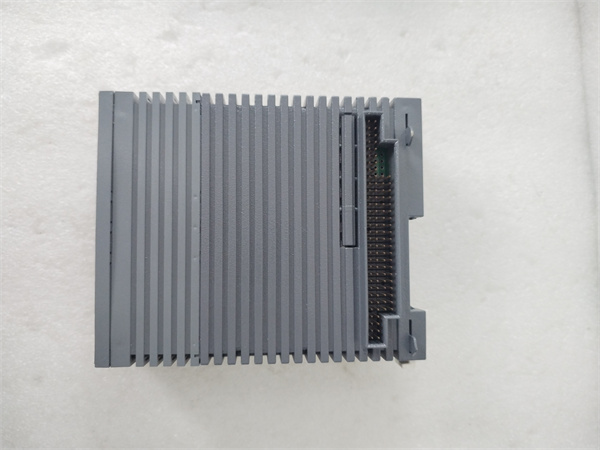

The WOODHEAD DRL – DPM – BKF is a sophisticated communication module crafted by WOODHEAD, a well – respected name in the industrial connectivity and automation solutions landscape. This module is designed to be a pivotal component in industrial systems, enabling seamless data transfer and connection across various devices.

Part of WOODHEAD’s comprehensive product portfolio, the DRL – DPM – BKF serves as a vital link in industrial automation setups. It is engineered to efficiently connect different elements within a system, facilitating the smooth flow of data. With its 1 – output – channel configuration, it offers focused and reliable data transmission capabilities. Whether it’s integrating with programmable logic controllers (PLCs), human – machine interfaces (HMIs), or I/O modules, the WOODHEAD DRL – DPM – BKF ensures that the communication infrastructure of an industrial system remains robust and efficient. This makes it an ideal choice for industries where precision and reliability in data transfer are of utmost importance.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DRL – DPM – BKF |

| Manufacturer | WOODHEAD |

| Product Type | Communication Module |

| Output Channels | 1 |

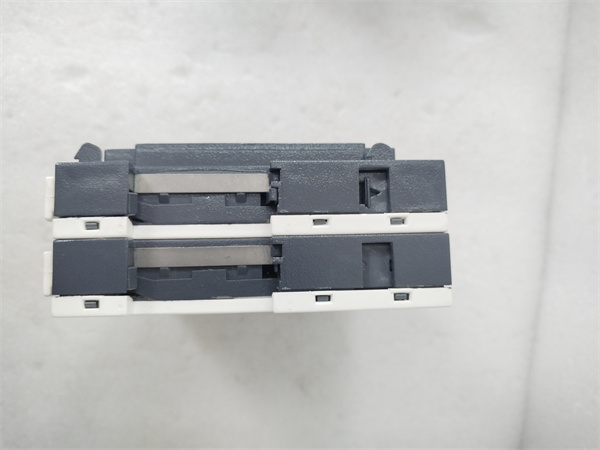

| Connector Type | Plug – type |

| Communication Protocols | Supports RS – 485, RS – 232, Ethernet |

| Compatibility | Compatible with PLCs, HMIs, I/O modules |

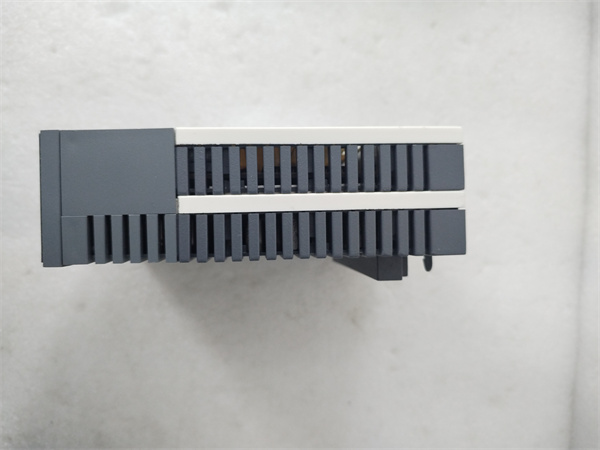

| Mounting Options | IP20 – rated for cabinet – mount applications; Optional IP67/69K for field – mount |

| Physical Dimensions | Compact design suitable for industrial enclosures |

| Power Requirements | Operates within standard industrial power supply ranges |

DRL-DPM-BKF

Main Features and Advantages

Versatile Communication Protocols: The WOODHEAD DRL – DPM – BKF stands out with its support for multiple communication protocols, including RS – 485, RS – 232, and Ethernet. This versatility allows it to interface with a wide array of devices. In an industrial plant with a mix of legacy and modern equipment, the module can communicate with older RS – 485 – based sensors and actuators, while also being able to connect to state – of – the – art Ethernet – enabled control systems. This ensures seamless integration within complex industrial setups.

High – quality Connector Design: As a plug – type connector, the DRL – DPM – BKF offers secure and easy – to – install connections. The plug – type design reduces the risk of loose connections, which can be a common issue in industrial environments with vibration and movement. In manufacturing plants where equipment is constantly in operation, the reliable connection provided by this module minimizes the chances of communication disruptions, ensuring continuous and stable data transfer.

Flexible Mounting Options: With an IP20 – rated design for cabinet – mount applications, it is well – suited for installation within control panels. For more demanding environments, the optional IP67/69K protection – rated version allows for field – mount installation. In outdoor industrial applications such as oil and gas pipelines or mining operations, the IP67/69K – rated DRL – DPM – BKF can withstand harsh conditions, including dust, water, and extreme temperatures, maintaining its communication integrity.

Application Field

Industrial Automation: In manufacturing plants, the WOODHEAD DRL – DPM – BKF plays a crucial role in connecting various components of the production line. It can link PLCs that control robotic arms, conveyor belts, and other machinery to HMIs for real – time monitoring and control. For example, in an automotive assembly plant, the module enables seamless communication between the PLCs controlling the movement of robotic arms during vehicle assembly and the HMI in the control room, allowing operators to monitor and adjust the production process.

Robotics: In robotic applications, the DRL – DPM – BKF is used to transfer data between the robot controller and sensors or actuators on the robot itself. In a pick – and – place robotic system in a warehouse, the module helps in transmitting data from sensors that detect the position of objects to be picked up to the robot controller, ensuring accurate and efficient operation of the robot.

Stage Lighting and Entertainment: In the entertainment industry, for stage lighting setups, the DRL – DPM – BKF can be used to connect lighting control consoles to the actual lighting fixtures. It enables the smooth transfer of control signals, allowing for precise and synchronized lighting effects during concerts, theater performances, and other live events.

DRL-DPM-BKF

Related Products

- WOODHEAD APP – ETH – PCU PCU2000ETH: This is an Ethernet – enabled data acquisition device. While the DRL – DPM – BKFfocuses on communication and connection in terms of protocols and physical connections, the PCU2000ETH is more about high – speed data collection. However, in some industrial scenarios, they can complement each other. For instance, the DRL – DPM – BKF can be used to transfer the data collected by the PCU2000ETH to other parts of the industrial network.

- WOODHEAD SST – PB3 – PCU: An interface module. It has different functionality compared to the DRL – DPM – BKF. The SST – PB3 – PCU may be more focused on PROFIBUS – related interfaces, while the DRL – DPM – BKFoffers a broader range of communication protocol support. In an industrial setup where PROFIBUS is the dominant network, the SST – PB3 – PCU can be used in conjunction with the DRL – DPM – BKF to handle different communication requirements.

- WOODHEAD EASYGEN – 3200: A thermocouple analog – input module. It is completely different in function from the DRL – DPM – BKF. The EASYGEN – 3200 is used for converting analog signals from thermocouples into digital data that can be processed by control systems. But in a complex industrial process control system, both the DRL – DPM – BKFfor communication and the EASYGEN – 3200 for temperature data acquisition can be part of the overall system, working together to ensure smooth operation.

- WOODHEAD SST – PFB – SLC – ADP: A module designed for specific applications related to SLC (Siemens Logic Controller) communication. It has a more targeted use case compared to the DRL – DPM – BKFwhich has a more general – purpose communication approach. In a Siemens – based industrial system, the SST – PFB – SLC – ADP can be used for SLC – specific communication tasks, while the DRL – DPM – BKF can handle communication with other non – SLC devices or for more general – network – level communication.

- WOODHEAD SST – DN4 – PCU: A communication module with different communication capabilities. It may have different data transfer rates or support different types of industrial networks compared to the DRL – DPM – BKF. In some industrial setups where multiple communication channels with varying requirements are needed, both the DRL – DPM – BKFand the SST – DN4 – PCU can be deployed to meet the diverse communication needs.

Installation and Maintenance

Pre – installation preparation: Before installing the WOODHEAD DRL – DPM – BKF, carefully review the installation manual provided by WOODHEAD. Ensure that the installation environment meets the specified temperature, humidity, and electrical requirements. If choosing the IP20 – rated version for cabinet – mount, select an appropriate location within the control panel, allowing for easy access for future maintenance. For the IP67/69K – rated field – mount option, ensure that the installation area is suitable for outdoor or harsh – environment installation. Prepare all necessary tools, such as screwdrivers and wire strippers. Disconnect the power supply to the relevant part of the industrial system to avoid electrical hazards during installation. Connect the module according to the provided wiring diagram, making sure that all connections are secure.

Maintenance recommendations: Regularly inspect the WOODHEAD DRL – DPM – BKF for any signs of damage, such as loose connections, cracks in the housing, or abnormal heat generation. Check the communication status of the module using appropriate diagnostic tools. In case of communication failures, first verify the integrity of the cables and connections. If using the module in a harsh environment, clean it periodically to remove dust, dirt, or moisture that could affect its performance. Update the module’s firmware to the latest version provided by WOODHEAD to ensure optimal performance and compatibility with other devices in the industrial network. If any hardware – related issues are detected, contact WOODHEAD’s technical support team for guidance on replacement or repair.

Product Guarantee

WOODHEAD offers a comprehensive product guarantee for the WOODHEAD DRL – DPM – BKF. The module undergoes strict quality control procedures during manufacturing to meet high – standard industrial requirements. WOODHEAD provides a warranty period, during which, if any manufacturing defects are found, they will repair or replace the module free of charge. Their dedicated technical support team is available to assist customers with any installation, operation, or maintenance questions. Whether it’s helping with complex network integration or troubleshooting communication issues, WOODHEAD is committed to ensuring that customers can rely on the DRL – DPM – BKF for their industrial communication needs. This guarantee gives customers confidence in using the product in their critical industrial applications, knowing that they are backed by a reliable and experienced manufacturer.