Description

Product Overview

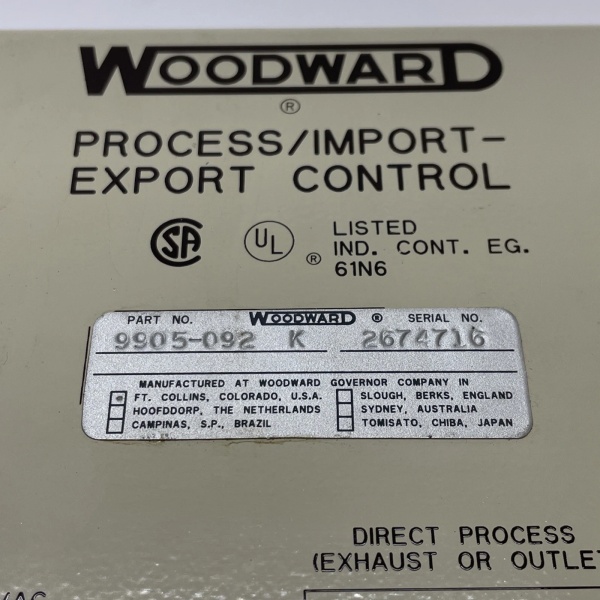

The Woodward 9905-092K is a 2301A series load sharing and speed control module designed for industrial prime movers (diesel engines, gas engines, steam turbines, gas turbines). It serves as a critical component in parallel power generation systems, enabling precise speed regulation and seamless load distribution across multiple generator sets. As part of Woodward’s 2301A ecosystem, the 9905-092K is widely used in industries where stable power output and efficient load management are paramount—such as power plants, cogeneration facilities, and marine propulsion systems.

The 9905-092K’s primary role is to maintain constant speed (isochronous mode) or adjust speed based on load (droop mode) while distributing electrical load evenly across paralleled generators. This ensures optimal performance, reduces equipment wear, and complies with grid frequency requirements. The “K” suffix indicates enhanced process import/export control functionality, allowing integration with external process variables (e.g., temperature, pressure) for advanced control strategies.

Woodward 9905-092K

Key Technical Specifications

The 9905-092K’s technical parameters are tailored for harsh industrial environments and high-precision control, building on the 2301A series’ proven design:

-

Input Voltage:

-

Low voltage: 20–40 V DC (nominal 24 V DC).

-

High voltage: 90–150 V DC / 88–132 V AC (45–440 Hz).

-

-

Speed Range: Switch-selectable (500–1500 Hz, 1000–3000 Hz, 2000–6000 Hz, 4000–12,000 Hz) to accommodate different prime mover types.

-

Control Modes:

-

Isochronous Mode: Maintains constant prime mover speed (±0.1% tolerance) for standalone or isolated bus operation.

-

Droop Mode: Adjusts speed based on load (adjustable droop percentage) for parallel operation with other generators.

-

-

Actuator Compatibility: Works with Woodward proportional actuators (e.g., EG-3P) for fuel/steam valve positioning.

-

Process Control: Supports import/export of process variables (e.g., 4-20 mA signals) for integration with external systems (e.g., DCS, SCADA).

-

Operating Temperature: –40°C to +70°C (–40°F to +158°F) (IEC 60068-2 compliant).

-

Protection Rating: IP20 (panel mount) – suitable for indoor industrial cabinets.

-

Dimensions: ~15.2 cm × 5.1 cm × 20.3 cm (6 in × 2 in × 8 in) (compact for DIN rail or panel installation).

-

Weight: ~0.7 kg (1.5 lbs) (lightweight for easy handling during maintenance).

Field Application & Problem Solved

In industrial power generation, unstable speed (due to load changes or grid fluctuations) and uneven load distribution (across parallel generators) can lead to:

-

Grid frequency deviations (triggering penalties or equipment shutdowns).

-

Overload of individual generators (reducing lifespan).

-

Inefficient energy transfer (increasing fuel consumption).

The 9905-092K addresses these challenges through:

-

Precision Speed Regulation:The module uses phase-locked loop (PLL) algorithms to maintain speed within ±0.1% of the setpoint (isochronous mode). This stability is critical for power plants, where frequency deviations of ±0.5 Hz can trigger grid penalties.

-

Automatic Load Sharing:In parallel operation (droop mode), the 9905-092K distributes load evenly across generators (±1% accuracy). For example, a hospital using three paralleled generators with the 9905-092K reduced generator maintenance costs by 20% due to balanced load distribution.

-

Flexible Mode Switching:The module supports isochronous (constant speed) and droop (load-dependent speed) modes, allowing it to adapt to different operational requirements (e.g., standalone backup power vs. parallel grid-connected operation).

-

Process Integration:The “K” suffix enhances process import/export control, enabling the module to adjust speed/load based on external process variables (e.g., steam pressure, gas flow). This is particularly valuable in cogeneration facilities, where thermal and electrical loads must be balanced.

Typical Applications:

-

Power Generation: Controlling steam turbines/gas turbines in coal-fired/gas-fired power plants to maintain grid frequency stability.

-

Cogeneration: Balancing electrical load and thermal steam demand in industrial facilities (e.g., paper mills, refineries).

-

Marine Propulsion: Controlling shipboard turbines/engines for auxiliary power generation with load sharing.

Installation & Maintenance Pitfalls (Expert Tips)

To ensure optimal performance and reliability of the 9905-092K, follow these best practices:

-

Verify Power Supply Compatibility:

-

Confirm that the input voltage (20–40 V DC / 90–150 V DC / 88–132 V AC) matches the module’s rating. Mismatched voltage can damage the internal circuitry—we once resolved a controller failure by replacing a 48 V DC power supply with a 24 V DC unit.

-

-

Calibrate Speed Sensors:

-

Use a precision tachometer to calibrate the prime mover’s speed sensor (e.g., magnetic pickup) before installing the 9905-092K. Incorrect sensor calibration can lead to speed deviations—we fixed a recurring frequency error in a power plant by adjusting the sensor gap.

-

-

Test Load Sharing Logic:

-

After installation, test the load sharing logic using a resistive load bank. Verify that the 9905-092K distributes load evenly across generators (±1% accuracy)—this step prevents issues like “one generator taking all the load” during operation.

-

-

Perform Regular Maintenance:

-

Inspect the 9905-092K annually for signs of wear (e.g., cracked casings, loose connections). Clean the module’s potentiometers with isopropyl alcohol to remove dirt and debris, which can affect parameter settings.

Woodward 9905-092K

-

Technical Deep Dive & Overview

The 9905-092K operates on Woodward’s 2301A analog control platform, which combines a feedback loop with adjustable gain settings to deliver precise speed and load control. Here’s a simplified breakdown of its workflow:

-

Signal Reception:The module receives input signals from:

-

Speed sensor (magnetic pickup) monitoring prime mover shaft rotation.

-

Load sensor (current transformer) measuring generator output current.

-

Process variables (4-20 mA signals) from external systems (e.g., DCS).

-

-

Processing & Control:The analog circuitry processes the input signals using PID (Proportional-Integral-Derivative) algorithms to calculate the required fuel/steam flow. The isochronous mode maintains constant speed by adjusting the actuator output, while the droop mode adjusts speed based on load.

-

Output & Actuation:The module sends a control signal to the prime mover’s actuator (e.g., fuel valve) to adjust the fuel/steam flow, thereby regulating speed and load. Simultaneously, it monitors for fault conditions (e.g., overspeed, low oil pressure) and triggers alarms if necessary.

-

Communication & Monitoring:The 9905-092K is compatible with Woodward’s SPM-A synchronizers and other power generation controls, allowing for seamless integration with plant DCS/SCADA systems. Operators can use Woodward’s 2301A Explorer software to visualize trends, adjust setpoints, and perform diagnostics remotely.

What sets the 9905-092K apart is its balance of precision and simplicity. Unlike digital controllers, the analog platform eliminates the need for complex programming, making it easy to install and maintain—critical for 24/7 operations like power plants. The “K” suffix further enhances its versatility by adding process import/export control, making it suitable for advanced cogeneration and industrial applications.

Final Notes

The Woodward 9905-092K is a reliable and essential component of Woodward’s 2301A series, enabling precise load sharing and speed control for industrial prime movers. Its compatibility with multiple prime mover types, flexible control modes, and enhanced process integration make it ideal for mission-critical applications where stable power output is non-negotiable.

When installing or maintaining the 9905-092K, always adhere to Woodward’s guidelines and consult with a certified technician to ensure optimal performance. For more detailed information, refer to Woodward’s official 2301A Series Load Sharing and Speed Control Manual (Document # 2301A-OM-001) or contact Woodward’s customer support for application-specific advice.