Description

Product Overview

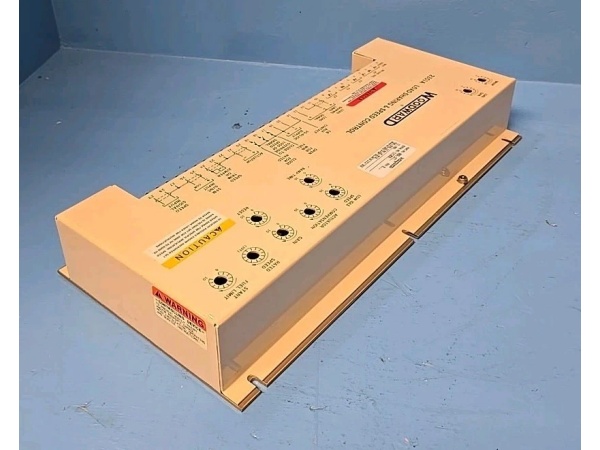

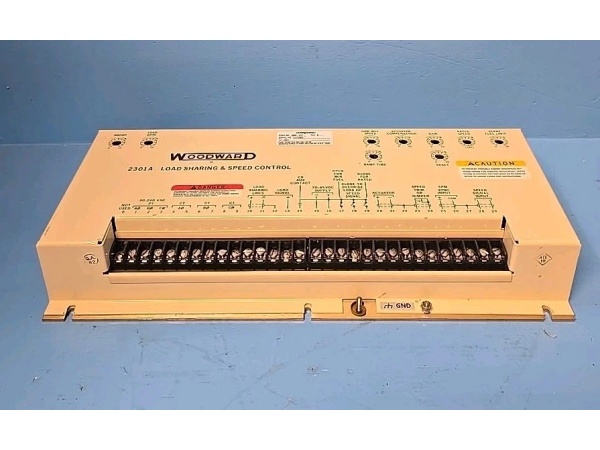

The Woodward 9905-373 is a communication-enhanced variant of the 2301A series electronic load sharing and speed control module, designed for industrial prime movers (e.g., diesel engines, gas turbines, generators) in smart industrial environments where remote monitoring, data logging, and integration with plant DCS/SCADA systems are critical. As part of Woodward’s 2301A ecosystem, it retains core functionalities—precision speed regulation and load sharing—while adding Modbus RTU communication and expanded diagnostic capabilities, making it ideal for modern power systems requiring real-time data exchange.

The 9905-373’s primary role is to maintain constant speed (isochronous mode, ±0.1% tolerance) or adjust speed based on load (droop mode, 0–15% adjustable droop) while distributing electrical load evenly across paralleled generators (±1% accuracy). Its communication feature enables operators to remotely adjust setpoints, monitor faults, and analyze performance trends—reducing on-site maintenance visits and improving system uptime.

Key Technical Specifications

Insights from Woodward 2301A series documentation and industrial automation supplier listings (e.g., AutomationDirect, Woodward’s legacy catalogs) reveal the following parameters for the 9905-373:

-

Input Voltage: 20–40 Vdc (nominal 24 Vdc) – optimized for standard industrial DC power systems.

-

Control Modes:

-

Isochronous Mode: Maintains constant prime mover speed (±0.1% tolerance) for standalone/isolated bus operation.

-

Droop Mode: Adjusts speed based on load (adjustable droop percentage, 0–15%) for parallel operation with other generators.

-

-

Communication Interface: Modbus RTU (RS-485) – supports up to 247 devices on a single bus; baud rates: 9600–19200 bps.

-

Actuator Compatibility: Works with Woodward proportional actuators (e.g., EG-3P, PG-PL, EPG-2) for fuel/steam valve positioning.

-

Operating Temperature: -30°C to +70°C (-22°F to +158°F) – suitable for semi-harsh industrial environments.

-

Certifications: CE, UL, CSA – compliant with international industrial safety standards.

-

Dimensions: Compact form factor (~280 mm × 210 mm × 90 mm) – fits standard 19-inch control cabinets.

-

Weight: ~4.1 kg (9.0 lbs) – lightweight for easy handling.

-

Diagnostic Features: 6x LED indicators (power, run, sync, comm, fault, mode) + non-volatile fault log (stores last 100 events with timestamps, error codes, and system parameters).

-

Output Signal: 0–200 mA (sink) – drives actuators for real-time fuel/steam flow adjustment.

WOODWARD 9905-377

Field Application & Problem Solved

In smart industrial power systems requiring remote monitoring or integration with plant-wide control networks, the 9905-373 addresses:

-

Lack of Remote Visibility: Base 2301A modules (e.g., 9905-003) offer only local LED status, making it impossible to monitor performance from a central control room. The 9905-373’s Modbus RTU enables real-time data transmission to DCS/SCADA systems.

-

Limited Diagnostic Depth: Basic models store <20 fault events, complicating root-cause analysis for intermittent issues. The 9905-373’s 100-event log captures long-term trends (e.g., sensor drift, actuator wear).

-

Grid Modernization Needs: Smart grids require generators to report status (frequency, load, faults) to utility operators. The 9905-373’s communication capability facilitates compliance with grid codes (e.g., IEEE 1547).

Typical Applications:

-

Smart Grid-Connected Power Plants: Remote monitoring of gas turbine generators for load balancing and fault reporting.

-

Marine Integrated Control Systems: Shipboard generator control with data integration into the vessel’s automation network.

-

Industrial Cogeneration with DCS: Balancing electrical/thermal loads in paper mills, with real-time data sent to the plant DCS.

Installation & Maintenance Pitfalls (Expert Tips)

To ensure reliable operation and communication with the 9905-373:

-

Modbus Bus Configuration:

-

Assign a unique slave address (1–247) to the module. Use shielded twisted-pair cable (RS-485) with termination resistors (120Ω) at both ends of the bus to minimize noise.

-

-

Validate Communication Protocol:

-

Confirm the DCS/SCADA system uses Modbus RTU (not TCP) and matches the module’s baud rate (e.g., 19200 bps, 8 data bits, 1 stop bit, no parity). Test with a Modbus scanner (e.g., ModScan) before full integration.

-

-

Calibrate Sensors in Live Environment:

-

For isochronous mode, use a precision frequency meter to calibrate the prime mover’s speed sensor (magnetic pickup) after installation. Adjust the setpoint via Modbus to match the grid frequency (50/60 Hz).

-

-

Leverage Diagnostic Logs:

-

Schedule monthly downloads of the 100-event fault log to identify recurring issues (e.g., “actuator response delay” indicating valve wear).

-

Technical Deep Dive & Overview

The 9905-373 operates on Woodward’s 2301A analog control platform with a digital communication overlay:

-

Signal Reception & Processing:

-

Accepts inputs from speed sensors (magnetic pickup), load sensors (CTs), and operator inputs (local potentiometers or Modbus remote setpoints). Analog circuitry with PID algorithms calculates fuel/steam flow adjustments.

-

-

Control Modes:

-

Isochronous: Locks speed to a setpoint (±0.1% accuracy) for grid-connected operation.

-

Droop: Adjusts speed based on load (0–15% droop) for parallel generator load sharing.

-

-

Modbus RTU Integration:

-

A dedicated microcontroller handles communication, translating internal status (speed, load, faults) into Modbus registers (e.g., Holding Register 40001 = speed setpoint, Input Register 30001 = actual speed).

-

-

Diagnostic Logging:

-

A non-volatile flash memory stores 100 events, including timestamps (RTC-enabled), error codes (e.g., “E01” = overspeed), and system snapshots (voltage, temperature).

WOODWARD 9905-377

-

Distinction from Similar Models:

-

Communication Capability: Modbus RTU vs. base 2301A models (no communication).

-

Expanded Fault Log: 100 events vs. 9905-092’s 50 events or 9905-228’s 20 events (SPM-A series).

-

Wider Droop Range: 0–15% vs. standard 0–10% for flexible parallel load sharing.

Final Notes

The Woodward 9905-373 is a communication-enhanced 2301A series module designed for industrial prime mover control in smart industrial environments requiring remote monitoring and integration with plant control networks. Its Modbus RTU capability, expanded diagnostic logging, and flexible droop control make it ideal for modern power systems, marine automation, and cogeneration facilities.

-

Choose 9905-373 if: You need remote monitoring via Modbus RTU, a 100-event fault log, or a wider droop range (0–15%).

-

Consider Alternatives: For basic synchronization, use 9905-028 (SPM-A); for harsh environments, use 9905-096 (high-performance 2301A).

Always refer to Woodward’s 2301A Communication-Enhanced Module Manual (Document # 2301A-COM-001) for installation guidelines. For Modbus configuration, use Woodward’s Modbus Setup Tool (Software # MST-002).