Description

Product Overview

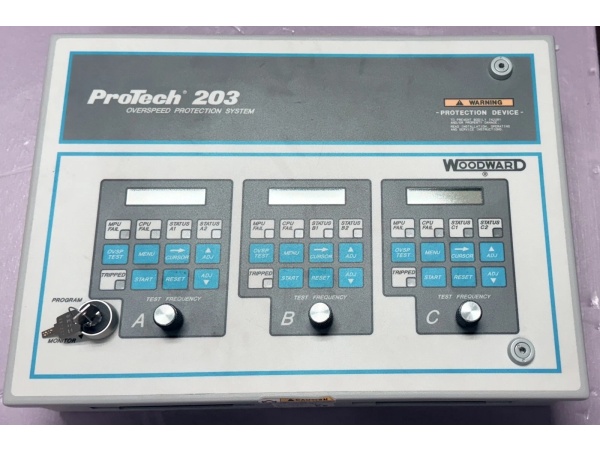

The Woodward 9907-345 is a triple-redundant overspeed protection system from Woodward’s ProTech 203 series, designed to prevent catastrophic failure of industrial prime movers (e.g., steam turbines, gas turbines) due to overspeed conditions. It replaces traditional mechanical overspeed devices with a digital solution that offers higher reliability, programmability, and diagnostic capabilities.

As part of Woodward’s ProTech family, the 9907-345 is widely used in industries where turbine/engine safety is paramount—such as power generation, petrochemical processing, and marine propulsion. Its redundant sensing and fail-safe design ensure that overspeed events are detected and mitigated promptly, minimizing the risk of equipment damage or downtime.

Key Technical Specifications

The 9907-345’s technical parameters are tailored for high-reliability overspeed protection in harsh industrial environments:

-

Speed Sensing: 3 independent magnetic pickup (MPU) channels (100 Hz–32 kHz frequency range, 1–60 Vrms input).

-

Trip Logic: De-energize-to-trip (fail-safe) with 2-out-of-3 voting logic (requires 2 of 3 sensors to detect overspeed for a trip).

-

Response Time: <40 ms from overspeed detection to trip initiation (ensures rapid shutdown).

-

Input Voltage: 18–32 VDC (dual redundant inputs for enhanced reliability).

-

Operating Temperature: –40°C to +70°C (–40°F to +158°F; suitable for extreme industrial environments).

-

Enclosure Rating: NEMA 4X / IP66 (dust-tight, water-jet resistant; protects against harsh weather and contaminants).

-

Weight: 4.13 kg (9.1 lbs; compact for cabinet installation).

-

Certifications: SIL 3 (IEC 61508), CE, UL/cUL, Class I Div. 2 (Groups A, B, C, D) (compliant with international safety standards).

Woodward 8200-203

Field Application & Problem Solved

In industrial turbine/engine operations, overspeed (when the machine rotates faster than its design limit) can lead to catastrophic failure—such as turbine blade rupture, bearing damage, or even explosions. The 9907-345 addresses this critical safety issue through:

-

Redundant Speed Sensing:The 3 independent MPU channels ensure that overspeed is detected even if one sensor fails. The 2-out-of-3 voting logic prevents false trips (e.g., due to a single sensor glitch), ensuring that trips are only triggered when a genuine overspeed condition exists.

-

Fail-Safe Design:The de-energize-to-trip architecture means that the system will activate a trip (shut down the machine) if power is lost or the control system fails. This is critical for preventing “runaway” conditions where the machine continues to accelerate uncontrollably.

-

Hot-Swappable Modules:Individual speed-sensing modules can be replaced during operation without shutting down the protection system, minimizing maintenance downtime and maintaining continuous safety coverage.

Typical Applications:

-

Power Generation: Protecting steam turbines in coal-fired or gas-fired power plants from overspeed during load rejection (e.g., when the grid disconnects).

-

Oil & Gas: Safeguarding gas turbines used in compressor drives or generator sets from overspeed due to process upsets.

-

Marine Propulsion: Protecting shipboard turbines and engines from overspeed caused by propeller damage or loss of load.

-

Industrial Manufacturing: Preventing overspeed in turbines used for industrial processes (e.g., air separation, refrigeration).

Installation & Maintenance Pitfalls (Expert Tips)

To ensure optimal performance and reliability of the 9907-345, follow these best practices:

-

Sensor Placement:Install the 3 MPUs evenly around the machine’s shaft to ensure accurate speed sensing. Avoid placing sensors near sources of electromagnetic interference (EMI) (e.g., motors, transformers) to prevent false signals.

-

Voting Logic Configuration:Verify that the 2-out-of-3 voting logic is enabled in the system software. This ensures that trips are only triggered when 2 of the 3 sensors detect overspeed, reducing the risk of false trips.

-

Regular Testing:Perform annual functional tests of the 9907-345 using a signal generator to simulate overspeed conditions. This verifies that the system responds correctly and that the trip relays are functioning properly.

-

Hot-Swap Maintenance:Take advantage of the module’s hot-swappable design to replace faulty modules without shutting down the machine. This minimizes downtime and ensures continuous protection.

Woodward 8200-203

Technical Deep Dive & Overview

The 9907-345 operates on Woodward’s ProTech 203 digital platform, which combines redundant sensing, advanced logic, and fail-safe design to deliver reliable overspeed protection. Here’s a simplified breakdown of its workflow:

-

Speed Sensing:The 3 MPUs continuously monitor the machine’s shaft rotational speed, generating a frequency signal proportional to the speed.

-

Signal Processing:Each MPU’s signal is processed by a dedicated microcontroller, which calculates the speed and compares it to the pre-set overspeed threshold (e.g., 110% of rated speed).

-

Voting Logic:The microcontrollers communicate with each other to implement 2-out-of-3 voting. If 2 of the 3 microcontrollers detect an overspeed condition, a trip command is sent to the machine’s trip valve.

-

Trip Execution:The trip valve closes, shutting off the steam/gas supply to the machine and bringing it to a safe stop. The 9907-345 also records the peak speed and the time of the event for later analysis.

-

Reset & Recovery:After a trip, the system must be manually reset using the front-panel keypad. The reset process clears the trip condition and allows the machine to be restarted once the underlying cause of the overspeed has been addressed.

What sets the 9907-345 apart is its combination of redundancy, fail-safe design, and diagnostic capabilities. Unlike traditional mechanical overspeed devices, which are prone to wear and tear, the 9907-345 uses digital sensors and logic to provide reliable protection for years. Additionally, its peak speed recording feature helps engineers identify and mitigate potential issues before they escalate into catastrophic failures.

Final Notes

The Woodward 9907-345 is a critical component of any industrial turbine/engine control system, providing reliable overspeed protection to prevent catastrophic failure. Its triple-redundant design, fail-safe architecture, and hot-swappable modules make it an essential tool for ensuring machine safety in power generation, oil & gas, marine, and industrial applications.

When installing or maintaining the 9907-345, always adhere to Woodward’s guidelines and consult with a certified technician to ensure optimal performance. For more detailed information, refer to Woodward’s official ProTech 203 Overspeed Protection System Manual (Document # PT-203-OM-001) or contact Woodward’s customer support for application-specific advice.