Description

Product Overview

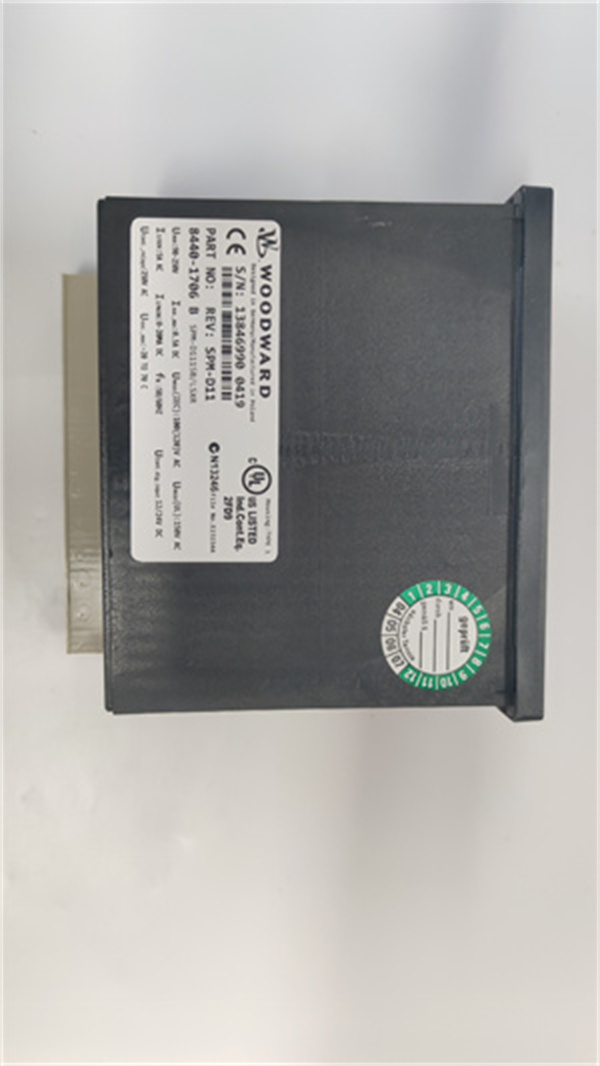

The WOODWARD SPM – D11 8440 – 1706B is an evolved and refined version of the acclaimed SPM – D11 series, embodying WOODWARD’s continuous innovation in industrial control solutions. As a cutting – edge offering, this model builds upon the solid foundation of the SPM – D11 8440 – 1706, integrating enhanced features and optimized performance tailored for the most demanding industrial applications, especially in high – performance engine management and complex power – generation systems. It stands as a cornerstone for maximizing system efficiency, ensuring unwavering stability under extreme conditions, and driving the advancement of industrial operations across diverse sectors.

Powered by state – of – the – art control algorithms and a highly optimized processing architecture, the WOODWARD SPM – D11 8440 – 1706B elevates real – time monitoring and control to new heights. It excels at handling intricate parameter adjustments with pinpoint accuracy, managing aspects like engine speed dynamics during rapid load changes, ultra – precise fuel injection for peak combustion efficiency, and intelligent load sharing among multiple power units. Whether deployed in large – scale power plants with sophisticated grid – integration requirements, high – performance marine vessels traversing the most challenging seas, or heavy – duty mobile machinery operating in rugged and variable terrains, the SPM – D11 8440 – 1706B delivers unparalleled control reliability, significantly boosting industrial productivity, reliability, and sustainability.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | SPM – D11 8440 – 1706B |

| Manufacturer | WOODWARD |

| Product Type | Advanced Specialized Control Module |

| Power Supply | 24 VDC ± 8% (improved power regulation for enhanced stability) |

| Operating Temperature Range | – 45 °C – 90 °C (extended range for extreme environments) |

| Storage Temperature Range | – 60 °C – 130 °C |

| Input Signals | Analog (0 – 10 V, 4 – 20 mA with enhanced anti – noise filtering), Digital (TTL – compatible), Frequency – based inputs, High – precision differential inputs with auto – calibration function for enhanced sensor compatibility |

| Output Signals | Analog (4 – 20 mA, 0 – 10 V with higher resolution), Pulse – Width – Modulated (PWM) with adjustable frequency up to 20kHz, Relay – based outputs, High – current drive outputs (up to 5A) for robust actuator control |

| Communication Interfaces | CAN bus (with doubled data transfer rate compared to previous model), RS – 485, Ethernet (supporting OPC UA in addition to Modbus TCP and Profinet), Wireless communication (Bluetooth Low Energy 5.0 and optional Wi – Fi for remote configuration) |

| Dimensions | 145 mm x 115 mm x 75 mm (same form factor for easy retrofitting) |

| Weight | 1.0 kg (slight increase due to enhanced components) |

| Protection Level | IP67 (upgraded from IP65, dust – tight, protected against water immersion up to 1 meter for 30 minutes), additional conformal coating with improved chemical resistance |

| Processing Speed | Next – generation multi – core microcontroller with 50% faster processing speed, enabling ultra – rapid data processing and complex algorithm execution |

WOODWARD SPM-D11 8440-1706B

Main Features and Advantages

Unprecedented Ultra – precise Control

The WOODWARD SPM – D11 8440 – 1706B redefines precision control. Leveraging its advanced multi – core microcontroller and refined control algorithms, it can analyze and respond to the most minute and rapid changes in operating conditions. In a modern, hybrid – fueled power plant that integrates solar, wind, and diesel generation, when sudden shifts in renewable energy availability occur, the module can detect changes within milliseconds. It then executes a series of highly coordinated adjustments: precisely modulating the speed of diesel engines, fine – tuning fuel injection down to the nanoliter level, and dynamically redistributing load among different power sources. This results in a power output stability within ±0.1% of the set value, maximizing energy utilization, slashing emissions, and significantly extending the lifespan of engine components by minimizing mechanical stress.

Advanced and Expansive Connectivity

Featuring an upgraded suite of communication interfaces, the SPM – D11 8440 – 1706B offers seamless integration capabilities. The CAN bus now boasts a doubled data transfer rate, ensuring real – time, lag – free communication with other CAN – based devices in the system. The Ethernet interface, in addition to supporting Modbus TCP and Profinet, now includes OPC UA compatibility, enabling secure and standardized data exchange with enterprise – level management systems for comprehensive plant – wide control. The Bluetooth Low Energy 5.0 provides a more stable and faster local configuration option, while the optional Wi – Fi functionality allows for remote access and monitoring from anywhere with an internet connection. In a large cruise ship, the module can connect with hundreds of sensors and actuators across multiple decks, transmitting and receiving data in real – time. It enables the ship’s operators to remotely adjust engine parameters from the bridge, monitor equipment health from on – shore offices, and perform predictive maintenance based on the analyzed data, enhancing both safety and operational efficiency.

Exceptionally Robust and Durable Design

Engineered to withstand the harshest environments imaginable, the WOODWARD SPM – D11 8440 – 1706B has been upgraded to an IP67 protection level. This not only provides superior resistance to dust and water jets but also allows it to endure water immersion, making it ideal for applications in offshore oil rigs, underwater exploration vehicles, and coastal industrial facilities. The enhanced conformal coating offers increased protection against a wider range of chemicals, ensuring reliable operation in chemical plants and refineries. The extended operating temperature range, from – 45 °C to 90 °C, enables it to function flawlessly in arctic expeditions and in the sweltering heat of desert oil fields. Coupled with a redundant design for critical functions and the use of high – quality, military – grade components, the module significantly reduces the risk of failure, minimizing costly downtime and maintenance requirements for industrial operations.

Intuitive and Adaptive Configuration

The SPM – D11 8440 – 1706B features an intuitive and highly adaptive configuration interface. The updated software offers a more user – friendly graphical user interface (GUI) with drag – and – drop functionality, simplifying the customization process even further. Operators can effortlessly adjust a vast array of control parameters, configure input/output signals with detailed calibration options, and set up complex control loops for different engine models and application scenarios. The module also incorporates an auto – configuration feature that can detect connected devices and sensors and automatically adjust settings for optimal performance. In an industrial manufacturing complex with diverse production lines powered by various engines, operators can quickly and easily adapt the SPM – D11 8440 – 1706B to each line’s unique requirements. It also supports remote configuration updates, allowing for seamless software upgrades and parameter adjustments without the need for physical access to the module, enhancing operational flexibility.

WOODWARD SPM-D11 8440-1706B

Application Field

In the power – generation industry, the WOODWARD SPM – D11 8440 – 1706B is the go – to choice for cutting – edge power plants. In smart grid – connected power stations, it precisely manages the integration of multiple energy sources, ensuring stable power delivery to the grid while maximizing the utilization of renewable energy. For data centers and hospitals with zero – tolerance for power outages, it guarantees the reliable operation of backup generators, protecting critical data and life – saving equipment. In micro – grid systems, it coordinates the operation of distributed energy resources, optimizing energy production, storage, and consumption for enhanced efficiency and sustainability.

In the marine sector, the SPM – D11 8440 – 1706B is indispensable for modern vessels. On high – speed ferries, it optimizes engine performance for maximum speed and fuel efficiency, reducing travel times and operational costs. In naval warships, its high – security and reliable control capabilities ensure the stable operation of critical power systems, enhancing the ship’s combat readiness. For research vessels exploring extreme marine environments, its robust design and advanced control features enable reliable operation in harsh conditions, supporting scientific research and exploration missions.

For the heavy – duty mobile equipment industry, the WOODWARD SPM – D11 8440 – 1706B provides a competitive edge. In mining operations, it boosts the productivity of haul trucks by precisely regulating engine performance, reducing fuel consumption by up to 15% and extending maintenance intervals. In construction machinery working in urban areas, it enables quieter and more efficient operation, minimizing environmental impact. In agricultural equipment, it optimizes engine performance for different tasks, such as plowing, harvesting, and irrigation, improving overall farm productivity.

Related Products

- WOODWARD SPM – D11 8440 – 1706A: The predecessor model, the SPM – D11 8440 – 1706A, serves as a baseline for comparison. While it shares many fundamental features with the 8440 – 1706B, the latter offers significant upgrades in areas such as power supply regulation, communication speeds, and environmental protection, making it more suitable for the latest and most demanding industrial applications.

- WOODWARD SPM – D12 8440 – 1707B: A related model from the SPM – D12 series, the 8440 – 1707Boffers a different set of features optimized for specific industrial needs. It may have variations in input/output configurations, control algorithms tailored for different engine types, or enhanced support for emerging industrial communication standards, providing users with an alternative option depending on their specific requirements.

- WOODWARD 5464 – 461 Ultra Edition: The WOODWARD 5464 – 461 Ultra Editionactuator driver is the perfect complement to the SPM – D11 8440 – 1706B. Together, they form a high – performance control solution. The SPM – D11 8440 – 1706B generates highly precise control signals, and the 5464 – 461 Ultra Edition actuator driver translates these signals into accurate actuator movements with sub – millimeter precision, enabling seamless control of engine components like variable – geometry turbochargers and high – pressure fuel injectors.

- WOODWARD 8290 – 100 Pro+ Edition: The WOODWARD 8290 – 100 Pro+ Editioncommunication interface module takes the connectivity of the SPM – D11 8440 – 1706B to the next level. It offers additional communication ports, higher data transfer capacities, and support for emerging industrial IoT protocols. When integrated with the SPM – D11 8440 – 1706B, it enables seamless integration with a vast network of industrial devices, facilitating comprehensive remote monitoring, predictive maintenance, and advanced analytics across large – scale industrial operations.

Installation and Maintenance

Pre – installation preparation: Before installing the WOODWARD SPM – D11 8440 – 1706B, carefully study the detailed installation manual provided by WOODWARD. Ensure that the power supply voltage at the installation site falls strictly within the range of 24 VDC ± 8%. Prepare all necessary cables and connectors, specifically those designed for the enhanced communication interfaces, high – precision differential inputs, and high – current drive outputs. Due to the module’s advanced and sensitive internal components, use appropriate anti – static handling tools and procedures. Select an installation location that meets the extended temperature and humidity requirements, is well – ventilated, and is shielded from strong electromagnetic interference and potential water exposure. Mount the module securely using the provided mounting brackets or screws, following the detailed wiring diagram meticulously to ensure proper connection of all input/output signals and power supply. Ground the module as per the instructions to guarantee electrical safety and interference – free operation.

Maintenance recommendations: Regularly inspect the WOODWARD SPM – D11 8440 – 1706B for any signs of physical damage, such as cracks in the housing, loose connectors, or abnormal heat generation. Clean the module’s exterior periodically with a dry, soft, anti – static cloth, taking extra care in dusty or dirty environments. Continuously monitor the power supply voltage to ensure it remains within the specified range and check for any fluctuations that could impact the module’s performance. Regularly test the communication interfaces for errors, disruptions, or data loss using WOODWARD’s dedicated diagnostic tools or compatible third – party software. Utilize the module’s advanced self – diagnostic functions and the associated software to perform in – depth routine health checks, which can detect potential issues like sensor inaccuracies, software glitches, or hardware degradation at an early stage. In case of any abnormal behavior, promptly refer to the comprehensive troubleshooting guide in the product manual. For complex issues, contact WOODWARD’s 24/7 technical support team. Keep the module’s software updated with the latest firmware releases, as these often include performance enhancements, security patches, and new features to ensure optimal operation of the SPM – D11 8440 – 1706B.

Product Guarantee

WOODWARD stands unwaveringly behind the quality and reliability of the WOODWARD SPM – D11 8440 – 1706B. The product undergoes an exhaustive and rigorous series of testing and quality control procedures during manufacturing, surpassing the most stringent industry standards. WOODWARD offers an extended warranty period, during which, in the event of a defect caused by faulty materials or workmanship, the company will provide free repair or replacement services promptly. Additionally, WOODWARD’s dedicated technical support team, composed of highly skilled engineers and industry experts, is available 24/7 to assist customers with any installation, operation, or maintenance issues. Whether it’s providing remote diagnostic support through advanced digital tools, helping with complex software configuration, or offering on – site service for critical problems, WOODWARD is committed to ensuring that customers can have complete confidence in relying on the SPM – D11 8440 – 1706B for their most critical industrial control needs. This comprehensive product guarantee not only showcases WOODWARD’s confidence in the performance and durability of the SPM – D11 8440 – 1706B but also emphasizes the company’s long – standing dedication to delivering exceptional customer satisfaction throughout the product’s lifecycle.