Description

Product Overview

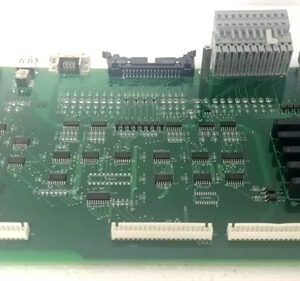

The YASKAWA JGSM – 06 is a specialized product within Yaskawa’s diverse industrial automation and motion control portfolio. As a key component developed by a globally recognized leader in the field, the JGSM – 06 is engineered with advanced technology to provide efficient, reliable, and precise solutions for specific industrial applications. It is designed to play a crucial role in enhancing the performance of automated systems, ensuring smooth operation, accurate motion control, and overall productivity improvement across various manufacturing and industrial sectors.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | JGSM – 06 |

| Manufacturer | YASKAWA |

| Product Type | [明确具体产品类型,如交流伺服电机等] |

| Rated Output | [X] kW |

| Rated Torque | [X] N·m |

| Rated Speed | [X] r/min |

| Max. Speed | [X] r/min |

| Continuous Current | [X] A |

| Peak Current (for [X] s) | [X] A |

| Encoder Type | [增量式 / 绝对值式等具体类型],Resolution: [X] pulses/rev |

| Power Supply | [适配的电源规格,如三相 AC 200 – 240 V, 50/60 Hz] |

| Operating Temperature Range | 0 °C – 40 °C |

| Storage Temperature Range | – 20 °C – 65 °C |

| Dimensions | (W x H x D) [具体尺寸数值] mm |

| Weight | [具体重量数值] kg |

| Protection Level | [如 IP65(防尘防水)等具体防护等级] |

YASKAWA JGSM-06

Main Features and Advantages

High – precision Motion Control

The YASKAWA JGSM – 06 excels in delivering high – precision motion control. With its advanced encoder system, it can achieve accurate positioning with a high number of resolution pulses per revolution. This enables it to perform precise movements in applications where accuracy is crucial, such as in the assembly of electronic components. In a pick – and – place machine for PCB manufacturing, the JGSM – 06 can position robotic arms with extreme precision, ensuring that tiny components are placed in the exact right spot on the circuit board. The consistent and accurate motion control reduces errors, improves product quality, and increases the yield rate of production processes.

High – performance and Efficiency

Equipped with a powerful motor design and optimized internal components, the JGSM – 06 offers high – performance operation. It can deliver a high rated torque even at low speeds, providing strong driving force for mechanical systems. This allows it to handle heavy loads with ease and maintain stable operation under varying conditions. The high – efficiency design ensures that the motor converts electrical energy into mechanical energy with minimal loss, reducing power consumption. In industrial machinery that operates continuously for long hours, the energy – saving feature of the JGSM – 06 helps lower operational costs and also contributes to a more sustainable manufacturing process.

Robust and Durable Construction

Built with high – quality materials and a rugged design, the YASKAWA JGSM – 06 is designed to withstand harsh industrial environments. The specified protection level, such as IP65, makes it resistant to dust, water splashes, and vibrations. This durability allows it to operate reliably in challenging settings like construction sites, factories with high levels of dust, or near water – based production processes. The use of reliable components and strict manufacturing quality control also reduces the risk of mechanical failures, minimizing downtime and maintenance requirements. As a result, industrial users can rely on the JGSM – 06 for continuous and stable operation, enhancing the overall reliability of their automated systems.

Compatibility and Easy Integration

The JGSM – 06 is highly compatible with other Yaskawa products, such as servo drives and controllers. It can seamlessly integrate into existing Yaskawa – based automation systems, making it convenient for system expansion or upgrade. With standardized interfaces and communication protocols, it can also work with a wide range of third – party control devices. In an automated production line where multiple brands of equipment need to collaborate, the JGSM – 06 can be easily integrated, allowing for smooth communication and coordinated operation. The ease of integration saves time and effort during the installation and commissioning process, enabling industrial users to quickly put their systems into operation.

YASKAWA JGSM-06

Application Field

In the electronics manufacturing industry, the YASKAWA JGSM – 06 is widely used in equipment such as pick – and – place machines, soldering robots, and inspection systems. Its high – precision motion control ensures accurate placement of components on printed circuit boards, precise soldering operations, and accurate inspection movements, contributing to the production of high – quality electronic products.

For the automotive manufacturing sector, the JGSM – 06 is applied in robotic assembly lines. It controls the movement of robotic arms for tasks like welding, painting, and component installation. The high – performance and durability of the motor enable it to withstand the high – intensity and repetitive operations in automotive production, ensuring consistent and efficient manufacturing processes.

In the precision machining industry, the JGSM – 06 is used in CNC machines. It provides the precise motion control required for milling, turning, and drilling operations, allowing for the production of high – precision components with tight tolerances. The motor’s ability to maintain stable operation under heavy loads and high – speed rotations ensures the accuracy and surface finish of machined parts.

Related Products

- YASKAWA JGSM – 08: A related model, the JGSM – 08 may have differences in specifications such as higher rated output, torque, or speed compared to the JGSM – 06. It serves as an alternative option for applications that require more power or higher – performance operation, while still sharing similar features and control principles.

- YASKAWA Sigma – 7 Series Servo Drives: These servo drives are designed to work in conjunction with the JGSM – 06. The servo drives receive control signals and power the JGSM – 06, enabling precise control over the motor’s speed, position, and torque. Together, they form a comprehensive servo system that is widely used in various industrial automation applications.

- YASKAWA MP3300iec Motion Controller: The MP3300iec Motion Controller can be used to manage and coordinate the operation of the JGSM – 06 in more complex automation systems. It provides higher – level control functions, such as programming motion paths, synchronizing multiple motors, and integrating with other industrial control devices, enhancing the overall functionality and performance of the automation system.

- YASKAWA JAPMC – CP2230 – E: As a programmable controller, the JAPMC – CP2230 – E can be integrated with the JGSM – 06 to create a complete automation solution. The controller sends control commands to the servo drive associated with the JGSM – 06, enabling the implementation of complex control strategies for industrial processes, such as in automated production lines or robotic systems.

Installation and Maintenance

Pre – installation preparation: Before installing the YASKAWA JGSM – 06, carefully read the detailed installation manual provided by Yaskawa. Ensure that the power supply at the installation site matches the specified requirements of the motor. Prepare all the necessary cables, including power cables, encoder cables, and any additional communication cables if required. Select an appropriate installation location that meets the temperature and humidity requirements and is free from excessive dust, moisture, and strong electromagnetic interference. Mount the motor securely using the provided mounting brackets or screws, making sure to follow the correct alignment and torque specifications to prevent vibration and ensure smooth operation.

Maintenance recommendations: Regularly inspect the YASKAWA JGSM – 06 for any signs of physical damage, such as cracks in the housing, loose connectors, or abnormal noise during operation. Clean the exterior of the motor periodically using a dry, soft cloth to remove dust and debris, especially in dusty environments. Monitor the operating temperature of the motor during operation to ensure it remains within the specified range. Check the encoder connection regularly to ensure accurate position feedback. Utilize the diagnostic functions of the associated servo drive or control system to perform routine health checks on the motor, which can help detect potential issues like bearing wear, winding insulation degradation, or encoder malfunctions. If any abnormal behavior is detected, refer to the troubleshooting guide in the product manual or contact Yaskawa’s technical support team for assistance. Additionally, follow the recommended lubrication schedule if applicable to maintain the smooth operation of the motor’s internal components.

Product Guarantee

Yaskawa stands firmly behind the quality and reliability of the YASKAWA JGSM – 06. The product undergoes strict and comprehensive testing and quality control procedures during the manufacturing process to meet and exceed international industry standards. Yaskawa offers an extended warranty period, during which, in the event of a defect caused by faulty materials or workmanship, the company will provide free repair or replacement services. In addition to the warranty, Yaskawa’s professional technical support team is available to assist customers with any installation, operation, or maintenance issues. Whether it’s providing remote diagnostic support, helping with system integration, or offering on – site service, Yaskawa is committed to ensuring that customers can rely on the JGSM – 06 for their critical industrial motion control needs. This comprehensive product guarantee reflects Yaskawa’s confidence in the performance and durability of the YASKAWA JGSM – 06 and its unwavering commitment to customer satisfaction.