Description

1. Detailed parameter table

| Parameter name | Parameter value |

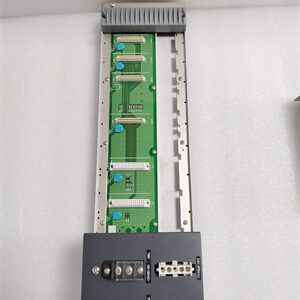

| Product model | ADV569-P00 |

| Manufacturer | YOKOGAWA |

| Product category | Digital Output Module |

| Number of Output Channels | 16 channels |

| Output Signal Type | Relay contact (Form A, 1C/O) |

| Rated Load Voltage | 250V AC / 30V DC |

| Maximum Switching Current | 2A (resistive load) |

| Breaking Capacity | 30W (DC), 500VA (AC) |

| Response Time | ≤10ms (operate), ≤5ms (release) |

| Isolation | 2500V AC (channel to system, channel to channel) for 1 minute |

| Operating Temperature Range | 0°C to 60°C |

| Storage Temperature Range | -20°C to 70°C |

| Dimensions | 30mm (W) x 100mm (H) x 150mm (D) |

| Weight | Approximately 0.3kg |

| Mounting | DIN rail or backplane mounting |

YOKOGAWA AFV10D-S41101

2. Product introduction

The YOKOGAWA ADV569-P00 is a robust digital output module engineered for reliable control signal distribution in industrial automation systems. As a key member of YOKOGAWA’s ADV series, it serves as the critical interface between control systems and field actuators, converting digital commands from DCS or PLC systems into physical switching actions.

This 16-channel module utilizes relay contacts to control external devices such as solenoid valves, motor starters, and alarm systems. Its design emphasizes durability and versatility, making it suitable for diverse industrial environments from manufacturing plants to utility facilities. The ADV569-P00 ensures precise execution of control commands, enabling seamless operation of complex automation processes. By providing reliable switching capabilities across multiple channels, it enhances system responsiveness and contributes to efficient process management in critical industrial applications.

3. Core advantages and technical highlights

High-power switching capability:

The ADV569-P00 delivers impressive switching performance with a maximum current rating of 2A and support for 250V AC/30V DC loads. This makes it suitable for controlling a wide range of industrial devices, from small solenoids to medium-sized motors. In manufacturing facilities, this capability allows direct control of conveyor belt motors or heating elements without requiring intermediate relays, simplifying system architecture and reducing potential failure points.

Enhanced electrical isolation:

With 2500V AC isolation between channels and from channels to the system, the ADV569-P00 provides superior protection against voltage transients and noise interference. This isolation is particularly valuable in industrial environments with high electromagnetic interference, such as near large motors or welding equipment. It prevents voltage spikes from damaging control system components and ensures stable operation even in electrically harsh conditions, reducing unplanned downtime.

Flexible relay configuration:

Featuring Form A (1C/O) relay contacts, the ADV569-P00 offers flexible integration with various field devices. The changeover contact design allows for both normally open and normally closed operation, accommodating different control logic requirements. This flexibility simplifies system design in applications like emergency shutdown systems, where fail-safe configurations are essential, and in process control loops requiring interlocking between different equipment.

Channel-independent operation:

Each of the ADV569-P00‘s 16 channels operates independently, with individual relays that can be controlled without affecting other channels. This independence enhances system reliability—if one channel fails, the remaining channels continue functioning. In critical applications such as power distribution control, this feature minimizes the impact of individual component failures, ensuring continuous operation of essential systems.

YOKOGAWA AFV10D-S41101

4. Typical application scenarios

In chemical processing plants, the ADV569-P00 plays a critical role in controlling valve manifolds and pump stations. It switches control signals for pneumatic valve actuators, isolation valves, and pump starters based on commands from the central DCS. For example, during batch processing, it sequentially activates different valves to direct flow through reaction vessels, ensuring precise control of chemical mixing and transfer. The module’s robust relay contacts handle the inductive loads from valve solenoids, providing reliable operation even in the presence of chemical fumes and temperature fluctuations.

Within water treatment facilities, the ADV569-P00 manages filtration systems and chemical dosing pumps. It controls backwash valves for sand filters, activating them based on pressure differential signals received from the control system. The module also regulates the operation of chemical injection pumps, ensuring accurate dosing of coagulants and disinfectants. Its ability to handle both AC and DC loads makes it versatile for integrating with different types of equipment, from AC-powered motorized valves to DC-driven dosing pumps, contributing to efficient water purification processes.

In food and beverage manufacturing, the ADV569-P00 controls packaging machinery and conveyor systems. It activates sealing mechanisms, label applicators, and conveyor section starters in sync with production line sensors. For instance, in a bottling plant, it triggers bottle capping machines when bottles reach the capping station and diverts defective products to reject bins using pneumatic pushers. The module’s reliable switching ensures precise timing in these high-speed applications, maintaining production efficiency while adhering to strict hygiene standards.

5. Related model recommendations

- ADV169-P01: A 16-channel digital input module that pairs with the ADV569-P00to form a complete digital I/O system. While the ADV569-P00 handles output signals, the ADV169-P01 collects input status data, enabling closed-loop control.

- ADV561-P01: An 8-channel digital output module with transistor outputs instead of relays, offering faster switching for applications requiring high-frequency operation. It complements the ADV569-P00in systems needing a mix of relay and transistor outputs.

- ADV569-P01: A variant of the ADV569-P00with LED status indicators for each channel, providing visual confirmation of output states for easier troubleshooting.

- AAI835-H50: An analog I/O module that works alongside the ADV569-P00in mixed-signal systems, handling continuous process variables while the ADV569-P00 manages discrete control actions.

- ADV551-P01: An 8-channel analog input module that monitors process parameters, which are then used by the control system to generate output commands executed by the ADV569-P00.

- ADV569-P10: A high-power version of the ADV569-P00with 5A switching capacity, designed for controlling larger loads such as industrial heaters and heavy-duty motors.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the YOKOGAWA ADV569-P00, ensure the mounting location maintains temperatures between 0°C and 60°C with relative humidity below 90% (non-condensing). Prepare insulated tools, a torque screwdriver (set to 0.5-0.8 Nm), and wire strippers for 14-22 AWG conductors. Disconnect all power sources to the control cabinet and field devices to prevent electrical hazards during installation.

Verify that the backplane or DIN rail is properly grounded and that wiring routes avoid high-voltage cables to minimize interference. Use twisted-pair cables for control signals, with separate runs for power and signal wiring. Check that field device loads are within the module’s rated specifications (2A max per channel) to prevent relay damage. Review the wiring diagram to ensure correct phase connections for AC loads, especially in three-phase applications.

Maintenance suggestions

Regular maintenance of the ADV569-P00 should include visual inspections for loose connections, damaged relays, or signs of overheating (discoloration, burning odors). Clean dust from the module surface using compressed air every six months to maintain proper ventilation. Test relay contacts annually using a multimeter to check for increased resistance, which indicates wear.

If a relay fails, replace the entire module with a YOKOGAWA-approved unit, as individual relays are not field-serviceable. Keep spare modules on hand for critical applications to minimize downtime. Monitor relay operation counts using the control system—replace modules after approximately 100,000 operations for high-reliability applications. Ensure firmware is updated to the latest version using YOKOGAWA’s configuration software to benefit from performance improvements.

7. Service and guarantee commitment

YOKOGAWA backs the ADV569-P00 with a 3-year warranty covering manufacturing defects and relay failures under normal operating conditions. Each module undergoes stringent testing, including temperature cycling and vibration testing, to ensure compliance with IEC 61131-2 and UL 508 standards.

Our global technical support team provides 24/7 assistance for installation, troubleshooting, and configuration, with on-site support available in major industrial regions. YOKOGAWA offers calibration services and replacement parts beyond the warranty period, ensuring long-term system reliability. We also provide training courses on proper handling of the ADV569-P00, helping customers maximize module lifespan and system performance. This commitment reflects our confidence in the ADV569-P00‘s durability and our dedication to customer success in industrial automation.