Description

1. Detailed parameter table

| Parameter name | Parameter value |

| Product model | ALE111-S50 |

| Manufacturer | YOKOGAWA |

| Product category | Digital Output Module |

| Number of Output Channels | 16 channels |

| Output Signal Type | Transistor (NPN), 24V DC |

| Maximum Output Current | 0.5A per channel, 4A total for all channels |

| Response Time | ≤10μs (on), ≤50μs (off) |

| Isolation | 250V AC (channel to system, channel to channel) |

| Operating Temperature Range | 0°C to 60°C |

| Storage Temperature Range | -20°C to 70°C |

| Dimensions | 30mm (W) x 100mm (H) x 150mm (D) |

| Weight | Approximately 0.2kg |

| Mounting | Backplane mounting (compatible with YOKOGAWA control systems) |

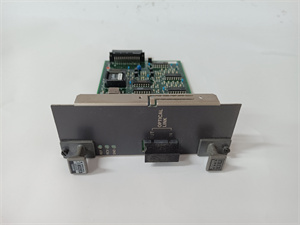

Yokogawa ALE111-S50

2. Product introduction

The YOKOGAWA ALE111-S50 is a high-speed digital output module designed for seamless integration into YOKOGAWA’s industrial automation systems. As a key component in digital control loops, it converts digital commands from the control system into electrical signals to drive various field devices.

This 16-channel module features transistor (NPN) outputs operating at 24V DC, making it ideal for controlling low-power devices such as solenoids, small motors, and indicator lights. The ALE111-S50 is engineered for rapid response, ensuring that control commands are executed with minimal delay. Its compact design and compatibility with YOKOGAWA’s control platforms make it suitable for industries including electronics manufacturing, packaging, and automated assembly lines. By providing reliable digital output capabilities, the YOKOGAWA ALE111-S50 enhances the precision and efficiency of industrial control systems, enabling timely and accurate operation of connected devices.

3. Core advantages and technical highlights

Ultra-fast response time:

The ALE111-S50 delivers exceptional response speeds, with turn-on times of ≤10μs and turn-off times of ≤50μs. This rapid action is crucial in high-speed automation applications, such as in electronics assembly lines where precise timing of component placement is essential. For example, when controlling a pick-and-place machine, the module’s fast response ensures that the solenoid-driven gripper operates with pinpoint accuracy, reducing cycle times and improving production throughput.

High channel density:

With 16 channels packed into a compact form factor, the ALE111-S50 offers high channel density, maximizing the number of controlled devices within limited rack space. In a packaging machine, this allows for independent control of multiple functions such as conveyor belts, sealing mechanisms, and label applicators using a single module. This not only reduces the overall system footprint but also simplifies wiring and installation, lowering both initial and maintenance costs.

Robust transistor outputs:

Equipped with NPN transistor outputs, the ALE111-S50 provides reliable switching for low-power devices. Each channel can handle up to 0.5A, with a total current limit of 4A across all channels, ensuring safe operation even when multiple devices are activated simultaneously. The transistor design offers longer operational life compared to mechanical relays, reducing the need for frequent replacements in high-cycle applications like automated testing equipment, where the module may switch on and off thousands of times per hour.

Enhanced electrical isolation:

Featuring 250V AC isolation between channels and from channels to the system, the ALE111-S50 effectively prevents electrical interference and protects the control system from voltage spikes. This isolation is particularly valuable in environments with numerous electrical devices, such as in a printing press where motors and heaters generate electromagnetic noise. It ensures that switching in one channel does not cause voltage fluctuations in others, maintaining stable operation of the entire control system.

Yokogawa ALE111-S50

4. Typical application scenarios

In electronics manufacturing, the ALE111-S50 is used to control various components of circuit board assembly machines. It activates solenoid valves that position solder paste dispensers, triggers vacuum grippers for picking and placing electronic components, and operates conveyor diverters to route PCBs to different processing stations. The module’s fast response time ensures that these actions are synchronized with high precision, critical for assembling small electronic components where even a 微小 delay can lead to defects.

In packaging lines for food and beverages, the ALE111-S50 controls label applicators, date coders, and film sealers. It switches on label applicators precisely as containers pass by, ensuring labels are applied straight and in the correct position. For shrink-wrapping machines, it activates heating elements at the right moment to seal packages, with the module’s multiple channels allowing independent control of different zones on the machine. The ALE111-S50‘s reliability ensures consistent packaging quality, reducing waste and improving production efficiency.

In automated testing systems, the ALE111-S50 triggers test probes, actuates clamping mechanisms, and controls indicator lights. In a automotive component testing facility, it can activate different test stations sequentially, clamping the component, initiating the test, and signaling pass/fail results through indicator lights. The module’s fast switching allows for rapid test cycles, increasing the number of components tested per hour and reducing overall testing costs.

5. Related model recommendations

- ALE112-S50: A 16-channel digital output module with PNP transistor outputs, offering the same features as the ALE111-S50but compatible with PNP-based control systems.

- ALD111-S50: A 16-channel digital input module that complements the ALE111-S50. While the ALE111-S50sends output signals, the ALD111-S50 receives input signals from sensors and switches, forming a complete digital I/O solution.

- ALE111-S30: An 8-channel digital output module with the same performance as the ALE111-S50but with fewer channels, suitable for smaller-scale applications.

- ALE211-S50: A 16-channel digital output module with relay outputs, designed for higher-power devices that exceed the current capacity of the ALE111-S50‘s transistor outputs.

- AIP830-111: An analog input processor module that can work alongside the ALE111-S50in mixed-signal systems, handling analog measurements while the ALE111-S50 manages digital control.

- ADV569-P00: A digital output module with relay contacts, offering an alternative to the ALE111-S50for applications requiring higher voltage handling but slower response times.

- ALE111-S50-R: A ruggedized version of the ALE111-S50with an extended temperature range (-20°C to 70°C), suitable for harsh industrial environments.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the ALE111-S50, ensure the control rack is powered off and the backplane is compatible with YOKOGAWA’s systems. Check that the ambient temperature is within 0°C to 60°C and the area is free from excessive dust and moisture. Prepare tools such as a torque screwdriver (0.5-1.0 Nm) and wire strippers for 22-16 AWG cables.

Use shielded cables for all connections, grounding the shield at both ends to minimize electromagnetic interference. Ensure the 24V DC power supply is stable and properly fused (5A recommended). Label each output channel clearly to correspond with the connected device, simplifying troubleshooting. Verify that the total current of all connected devices does not exceed 4A to prevent overloading the module.

Maintenance suggestions

Perform monthly visual inspections of the ALE111-S50 to check for loose connections, damaged cables, or signs of overheating. Clean the module’s surface with a dry, lint-free cloth to remove dust, taking care not to touch the electrical components. Monitor the module’s status through the control system’s diagnostic tools, looking for fault codes related to overcurrent or short circuits.

If a channel fails, first check the connected device and wiring for faults before replacing the module. When replacing the ALE111-S50, ensure the replacement module is configured with the same parameters as the original. Avoid exceeding the maximum current rating per channel or the total current limit, as this can damage the module. Store spare modules in a dry, temperature-controlled environment to maintain their performance.

7. Service and guarantee commitment

YOKOGAWA provides a 3-year warranty for the ALE111-S50, covering manufacturing defects and component failures under normal operating conditions. Each module undergoes rigorous testing during production, including environmental and electrical stress tests, to meet international standards such as IEC 61131-2 and UL 508.

Our global technical support team offers 24/7 assistance for installation, configuration, and troubleshooting, with online resources and documentation available for quick access. On-site support is available in major industrial regions to address complex issues promptly. YOKOGAWA also provides training programs to help customers maximize the performance of the ALE111-S50. This commitment to quality and service reflects our confidence in the module’s reliability and our dedication to ensuring customer success in industrial automation applications.