Description

1. Detailed parameter table

| Parameter name | Parameter value |

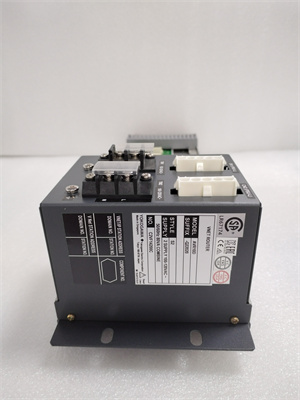

| Product model | AVR10D-Q22020 |

| Manufacturer | YOKOGAWA |

| Product category | AC Servo Drive |

| Rated Output Power | 2.0kW |

| Input Voltage | Single-phase AC 200-240V, 50/60Hz |

| Output Current | 10A (continuous), 20A (peak for 3 seconds) |

| Control Mode | Position control, speed control, torque control |

| Speed Range | 0.1-3000rpm |

| Positioning Accuracy | ±0.01° (with 17-bit encoder) |

| Communication Interface | EtherCAT, Modbus RTU |

| Operating Temperature Range | 0°C to 55°C |

| Dimensions | 120mm (W) x 210mm (H) x 180mm (D) |

| Weight | Approximately 2.5kg |

| Protection Features | Overcurrent, overvoltage, undervoltage, overheating, encoder error |

YOKOGAWA AVR10D-Q22020

2. Product introduction

The YOKOGAWA AVR10D-Q22020 is a high-performance AC servo drive designed for precision motion control applications in industrial automation. As part of YOKOGAWA’s AVR series, it delivers exceptional speed and position control for servo motors, making it ideal for applications requiring accurate and dynamic motion.

This 2.0kW drive supports single-phase AC input and offers versatile control modes—position, speed, and torque control—enabling seamless integration into various automation systems. The AVR10D-Q22020 features advanced servo algorithms that ensure smooth operation even at low speeds, with rapid response to command changes. Its compact design and rich communication options make it suitable for industries such as electronics manufacturing, packaging machinery, and precision assembly systems. By providing precise motion control capabilities, the YOKOGAWA AVR10D-Q22020 enhances production quality and efficiency in applications where movement accuracy is critical.

3. Core advantages and technical highlights

Multi-mode control flexibility:

The AVR10D-Q22020 supports three control modes—position, speed, and torque—easily switchable via software configuration. In electronics assembly, this versatility allows the same drive to control pick-and-place robots (position mode), conveyor speed (speed mode), and component insertion force (torque mode). This eliminates the need for multiple drive types, simplifying inventory and reducing training requirements for maintenance personnel.

High-precision positioning:

With positioning accuracy of ±0.01° when paired with a 17-bit encoder, the AVR10D-Q22020 excels in applications requiring micron-level precision. In semiconductor wafer handling systems, this accuracy ensures wafers are aligned correctly during photolithography processes, where even minor misalignment can ruin expensive components. The drive’s advanced control algorithms minimize following error, maintaining position accuracy even during rapid acceleration and deceleration.

EtherCAT communication:

Equipped with EtherCAT interface supporting 100Mbps communication, the AVR10D-Q22020 enables real-time synchronization of multiple axes. In a packaging machine with coordinated motion requirements, this allows precise timing between feed rollers, cutting mechanisms, and labeling heads—all controlled by synchronized AVR10D-Q22020 drives. The deterministic communication ensures cycle times as low as 1ms, critical for high-speed production lines.

Energy-efficient operation:

The AVR10D-Q22020 incorporates energy-saving features including regenerative braking and automatic idle mode. During deceleration phases in material handling systems, the drive converts kinetic energy back to electrical energy, feeding it back to the power supply instead of dissipating it as heat. This can reduce energy consumption by up to 20% compared to conventional drives in cyclic motion applications, lowering operational costs over time.

YOKOGAWA AVR10D-Q22020

4. Typical application scenarios

In electronics manufacturing, the AVR10D-Q22020 controls the X-Y positioning stages of printed circuit board (PCB) drilling machines. Operating in position control mode, it achieves the ±0.01mm accuracy required for drilling micro-vias in high-density PCBs. The drive’s fast response ensures rapid tool changes and positioning, reducing cycle times while maintaining precision—critical for meeting production targets in electronics assembly.

In packaging machinery, the AVR10D-Q22020 operates in speed control mode to drive film unwinding systems. It maintains constant tension through torque limiting, preventing film stretching or tearing during high-speed packaging of consumer goods. When integrated with a vision system, it can adjust speed dynamically to match product spacing, ensuring accurate label placement even when product sizes vary.

In medical device assembly, the AVR10D-Q22020 controls robotic arms in torque control mode during delicate operations like inserting catheters into packaging. It precisely limits force to prevent damage to sensitive components while maintaining consistent insertion depth. The drive’s smooth low-speed operation eliminates jerking motions that could compromise sterile conditions or component integrity.

5. Related model recommendations

- AVR10D-Q21010: A 1.0kW variant of the AVR10D-Q22020, suitable for smaller servo motors in applications like small part handling and light-duty robotics.

- AVR10D-Q23040: A 4.0kW higher-power model, providing an upgrade path from the AVR10D-Q22020for larger machinery such as injection molding machine actuators.

- AVR30D-Q32020: A three-phase input version of the AVR10D-Q22020with 2.0kW output, ideal for industrial environments with three-phase power infrastructure.

- F3PU10-0N: YOKOGAWA’s HMI panel that pairs with the AVR10D-Q22020for local parameter adjustment and real-time status monitoring of servo drive operation.

- ANB10D-425/CU2T: A digital input module that connects to the AVR10D-Q22020, providing emergency stop and limit switch signals for safe operation in automated systems.

- AVR10D-Q22020-S: A variant with enhanced vibration resistance, designed for mobile machinery applications where the AVR10D-Q22020‘s standard version may not withstand continuous vibration.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the AVR10D-Q22020, ensure the mounting location provides adequate ventilation with minimum 100mm clearance around the drive. The ambient temperature must remain within 0°C to 55°C, away from direct sunlight and heat sources. Prepare tools including torque screwdriver (1.2-1.5Nm), multimeter, and Ethernet cable tester.

Verify single-phase input voltage (200-240V) and install appropriate circuit protection (16A breaker). Use shielded cables for motor connections (0.75-1.5mm²) and encoder wiring, grounding shields at both ends to minimize electrical noise. Ensure proper grounding (PE) with wire cross-section ≥2.5mm². During wiring, separate power and signal cables to prevent interference.

Maintenance suggestions

Inspect the AVR10D-Q22020 monthly for loose connections, dust accumulation, or abnormal noise during operation. Clean ventilation filters quarterly using compressed air—more frequently in dusty environments. Check cooling fans annually for proper operation; replace if abnormal noise or reduced airflow is detected.

Monitor drive status via EtherCAT or front-panel display to track temperature, current, and error codes. Perform encoder calibration annually using YOKOGAWA’s configuration software to maintain positioning accuracy. If overheating occurs, check for ventilation blockages before replacing the drive. Store spare units in anti-static packaging in a dry environment (20-60% humidity).

When replacing the AVR10D-Q22020, transfer parameters using the backup function to ensure consistent operation. Use only YOKOGAWA-approved replacement parts, especially for encoder cables and power connectors, to maintain performance and safety certifications.

7. Service and guarantee commitment

YOKOGAWA provides a 3-year warranty for the AVR10D-Q22020, covering manufacturing defects and component failures under normal operating conditions. Each drive undergoes rigorous testing including temperature cycling, vibration testing, and endurance runs to ensure compliance with IEC 61800-5-2 and UL 508C standards.

Our technical support team offers specialized assistance for motion control applications, with 24/7 access to engineers experienced in servo system tuning. On-site commissioning support is available to optimize drive parameters for specific applications, ensuring maximum performance. YOKOGAWA provides software tools for drive configuration, diagnostics, and firmware updates, along with comprehensive training programs on AVR10D-Q22020 maintenance and troubleshooting. This commitment ensures customers achieve optimal performance and reliability from their servo systems throughout the product lifecycle.