Description

1. Detailed parameter table

| Parameter name | Parameter value |

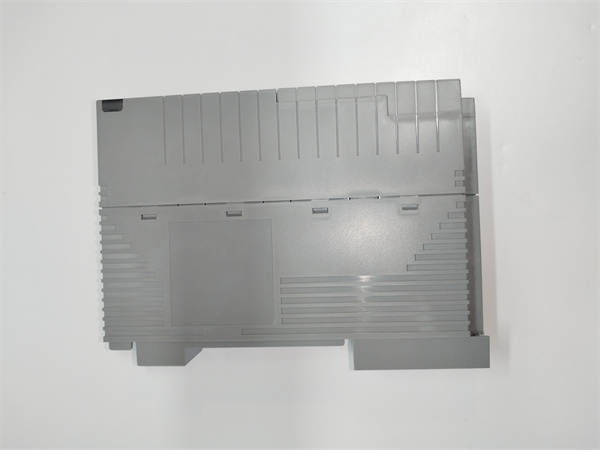

| Product model | CP401-10 S1 |

| Manufacturer | YOKOGAWA |

| Product category | Safety Programmable Logic Controller |

| Processing Speed | 0.1μs per basic instruction (safety and standard logic) |

| Program Memory | 2MB (expandable up to 8MB) |

| I/O Points | 256 standard I/O points, 128 safety I/O points (expandable up to 8192 standard, 4096 safety) |

| Safety Integrity Level | SIL 3 (per IEC 61508), PL e (per ISO 13849-1) |

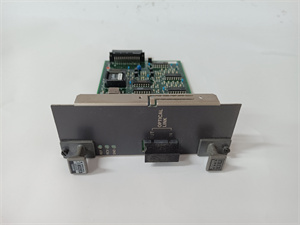

| Communication Interfaces | Ethernet (10/100Mbps), RS-232C, RS-485, Safety over Ethernet (SIL 3) |

| Supported Protocols | Modbus RTU/TCP, Ethernet/IP, Profibus DP, Safety Protocol |

| Operating Temperature Range | -10°C to 65°C |

| Power Supply | 100-240V AC, 50/60Hz (with redundant power input option) |

| Dimensions | 150mm (W) x 110mm (H) x 190mm (D) |

| Weight | Approximately 1.0kg |

| Certification | IEC 61508, ISO 13849-1, UL 508S, CE PED |

Yokogawa CP401-10 S1

2. Product introduction

The YOKOGAWA CP401-10 S1 is an enhanced safety-oriented variant of the CP401-10, designed specifically for industrial automation applications requiring functional safety. As a safety PLC, it integrates standard control logic with safety-related functions in a single platform, ensuring reliable protection of personnel, machinery, and processes.

This controller maintains the 0.1μs processing speed of the CP401-10 while adding dedicated safety processing capabilities. It supports both standard programming languages and safety-specific development environments, enabling engineers to implement complex safety interlocks alongside regular automation logic. The CP401-10 S1 achieves SIL 3 and PL e certifications, making it suitable for high-risk industries such as chemical processing, oil and gas, and power generation. By combining high-performance control with advanced safety features, the YOKOGAWA CP401-10 S1 provides a comprehensive solution for applications where safety and productivity are equally critical.

3. Core advantages and technical highlights

Safety-integrated architecture:

Unlike the standard CP401-10, the CP401-10 S1 features a dual-core architecture with separate processing for safety and standard logic, ensuring independence and integrity of safety functions. This design prevents common-cause failures, a key requirement for SIL 3 certification. In a chemical reactor control system, this means emergency shutdown logic (safety function) remains operational even if standard process control logic experiences a fault, preventing hazardous chemical releases.

Extended safety I/O capability:

The CP401-10 S1 supports 128 safety I/O points (expandable to 4096) in addition to standard I/O, providing dedicated channels for emergency stops, safety gates, and light curtains. These safety I/O modules feature built-in diagnostics and forced-guided contacts, ensuring reliable detection of faults such as short circuits or wire breaks. In an automotive press shop, this allows the PLC to monitor multiple emergency stop buttons and safety guards simultaneously, triggering an immediate stop if any safety barrier is breached.

Enhanced environmental resilience:

With an operating temperature range of -10°C to 65°C (wider than the CP401-10’s 0°C to 60°C), the CP401-10 S1 thrives in extreme environments. Its rugged construction includes conformal-coated circuit boards and enhanced vibration resistance (10g peak, 10-2000Hz), making it suitable for offshore platforms or mining operations where equipment is exposed to harsh conditions. This durability ensures safety functions remain operational even in challenging environments.

Advanced safety communication:

Equipped with Safety over Ethernet (SIL 3) in addition to standard interfaces, the CP401-10 S1 enables safe communication between distributed safety components. In a large-scale manufacturing plant with multiple production cells, this allows safety signals (like zone interlocks) to be transmitted across the network without compromising safety integrity. The deterministic safety communication ensures that safety-related messages are prioritized and delivered within 1ms, critical for coordinated emergency stops.

Yokogawa CP401-10 S1

4. Typical application scenarios

In oil refineries, the CP401-10 S1 controls both standard refining processes and safety shutdown systems. It regulates pump speeds and valve positions (standard logic) while continuously monitoring pressure sensors and flame detectors (safety logic). If overpressure is detected in a distillation column, the safety function triggers immediate valve closure and pump shutdown, preventing explosions. The SIL 3 certification ensures this safety function has a probability of failure on demand (PFD) below 10⁻⁴, meeting the strict safety requirements of the oil and gas industry.

In pharmaceutical manufacturing, the CP401-10 S1 manages sterile filling lines with critical safety and quality requirements. It controls conveyor speeds and filling nozzle positions (standard logic) while monitoring access doors to cleanrooms and pressure differentials (safety logic). If a cleanroom door is opened during filling, the safety function halts production to prevent contamination, protecting product integrity. The PLC’s data logging capabilities record both standard and safety events, providing comprehensive traceability for FDA compliance audits.

In power generation facilities, the CP401-10 S1 controls turbine operations and safety systems. It adjusts fuel flow and generator excitation (standard logic) while monitoring vibration levels and temperature sensors (safety logic). If excessive turbine vibration is detected, the safety function initiates a controlled shutdown to prevent catastrophic failure. The redundant power supplies and communication modules ensure the safety system remains operational during power fluctuations common in power plants.

5. Related model recommendations

- CP401-10: The standard non-safety variant, suitable for applications where functional safety certification is not required, offering a cost-effective alternative to the CP401-10 S1.

- CP401-05 S1: A smaller safety PLC with 0.2μs processing speed, 128 standard I/O, and 64 safety I/O points, ideal for medium-scale safety applications where the CP401-10 S1‘s capacity is unnecessary.

- F3PU20-0N-S: A safety-rated HMI panel that pairs with the CP401-10 S1, allowing operators to monitor both standard and safety statuses while preventing unauthorized changes to safety parameters.

- SIL3 I/O Modules: Dedicated safety input/output modules that expand the CP401-10 S1‘s safety I/O capacity, featuring built-in diagnostics and fault detection for high-reliability safety loops.

- CP601-10 S1: A high-performance safety PLC with 0.05μs processing speed and support for up to 16,384 standard I/O and 8,192 safety I/O points, providing an upgrade path from the CP401-10 S1for large-scale safety-critical systems.

- ANB10D-425/CU2T-S: A safety-rated digital input module that integrates with the CP401-10 S1, designed for connecting emergency stop buttons and safety sensors in SIL 3 applications.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the CP401-10 S1, ensure the mounting location meets the extended temperature range (-10°C to 65°C) and has at least 200mm clearance for ventilation. Use shielded, twisted-pair cables for all safety I/O connections, with separate routing from standard I/O cables to prevent interference. Verify the power supply meets 100-240V AC specifications and install redundant power feeds if required for safety integrity.

For safety 回路 wiring, use double-insulated cables with color-coded conductors (typically brown for 24V, blue for 0V, and yellow/green for PE). Ensure all safety connections are secured with torque screwdrivers (0.8-1.2Nm) to prevent loosening over time. Label safety I/O channels clearly with their safety function (e.g., “Emergency Stop – Press 1”) to facilitate troubleshooting.

Maintenance suggestions

Perform monthly visual inspections of the CP401-10 S1 and safety I/O modules, checking for loose connections, corrosion, or damage to safety circuits. Test all safety functions quarterly using YOKOGAWA’s safety testing software, which verifies that emergency stops and safety interlocks trigger within the required response time (<100ms for SIL 3 applications).

Backup both standard and safety program data weekly, storing backups in separate secure locations. Replace the lithium backup battery every 2 years (more frequently than the CP401-10) to ensure safety program retention during power outages. Calibrate safety sensors (e.g., light curtains, emergency stops) annually to maintain their performance within safety tolerances.

When performing maintenance on safety circuits, use the PLC’s “safe maintenance mode” to bypass non-critical safety functions temporarily while maintaining essential protections. Document all maintenance activities, including safety tests and component replacements, to maintain compliance with safety standards like IEC 61508.

7. Service and guarantee commitment

YOKOGAWA provides a 5-year warranty for the CP401-10 S1, with extended coverage for safety-related components. Each unit undergoes rigorous safety testing, including fault injection testing and safety integrity verification, to ensure compliance with IEC 61508 and ISO 13849-1.

Our safety-certified technical support team offers specialized 24/7 assistance for safety program development, verification, and validation. On-site safety commissioning support is available to ensure safety functions meet application requirements, with documentation provided for regulatory compliance. YOKOGAWA offers certified training programs on CP401-10 S1 safety programming and maintenance, helping customers maintain safety system integrity throughout the product lifecycle. We also provide safety lifecycle management services, including periodic safety audits, to ensure ongoing compliance with evolving safety standards.