Description

1. Detailed parameter table

| Parameter name | Parameter value |

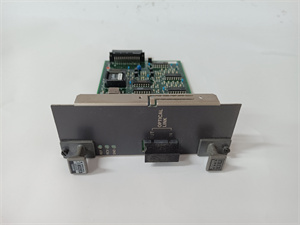

| Product model | PSCCM22AAN |

| Manufacturer | YOKOGAWA |

| Product category | Process Control System Module |

| Processor | 32-bit RISC, 800MHz |

| Memory | 2GB RAM, 8GB flash storage |

| I/O Interface | 4 x analog input (4-20mA), 2 x analog output (4-20mA), 8 x digital input, 4 x digital output |

| Communication Interfaces | Ethernet (10/100/1000Mbps), RS-485 |

| Supported Protocols | Modbus RTU/TCP, HART, PROFIBUS DP |

| Operating Temperature Range | 0°C to 60°C |

| Power Supply | 24V DC (redundant input support) |

| Power Consumption | ≤15W |

| Dimensions | 100mm (W) x 150mm (H) x 200mm (D) |

| Weight | Approximately 0.8kg |

| Certification | IEC 61131-2, UL 508, CE, ATEX Zone 2 |

YOKOGAWA PSCCM22AAN

2. Product introduction

The YOKOGAWA PSCCM22AAN is a compact yet powerful process control system module designed for precise monitoring and control of industrial processes. As a key component in YOKOGAWA’s process control product lineup, it integrates data acquisition, control logic execution, and communication capabilities, making it suitable for a wide range of industrial applications.

This module features a 32-bit RISC processor running at 800MHz, ensuring fast data processing and control response. With 2GB RAM and 8GB flash storage, it can handle complex control algorithms and store process data for analysis. The PSCCM22AAN offers a versatile I/O interface, including analog and digital channels, to connect with various sensors, actuators, and other field devices. Its Ethernet and RS-485 communication interfaces support multiple industrial protocols, enabling seamless integration with higher-level control systems (like the CP461-50 PLC) and HMI panels. Ideal for industries such as chemical processing, food and beverage, and water treatment, the YOKOGAWA PSCCM22AAN provides reliable and accurate process control to maintain product quality and optimize production efficiency.

3. Core advantages and technical highlights

High-precision analog signal processing:

The PSCCM22AAN is equipped with high-resolution analog input channels (16-bit) that can accurately measure 4-20mA signals from sensors such as pressure transmitters and temperature probes. In a chemical reactor system, this allows the module to detect even small changes in process variables (e.g., a 0.1°C temperature fluctuation), enabling precise control of heating or cooling systems to maintain optimal reaction conditions. The analog output channels provide 12-bit resolution, ensuring accurate control of valves and pumps with smooth adjustments.

Flexible control logic execution:

Supporting IEC 61131-3 programming languages (ladder logic, structured text, function block diagrams), the PSCCM22AAN allows engineers to implement custom control strategies tailored to specific processes. In a food processing plant, for example, it can execute a sequence that regulates mixing speed based on ingredient temperature and viscosity, ensuring consistent product texture. The module’s fast processor enables execution of complex control loops with a scan time as low as 10ms, critical for maintaining stability in dynamic processes.

Seamless integration with process instruments:

With built-in HART protocol support, the PSCCM22AAN can communicate with intelligent field devices beyond simple analog signals. In an oil refinery, it can not only receive a 4-20mA signal indicating flow rate from a HART-enabled flowmeter but also access diagnostic data (e.g., sensor health, calibration status) from the meter. This allows for predictive maintenance, as the module can alert operators to potential issues before they cause process disruptions, reducing unplanned downtime.

Redundant design for reliability:

The PSCCM22AAN supports redundant 24V DC power inputs, ensuring continuous operation even if one power supply fails. In a water treatment plant, where consistent control of chemical dosing is critical to public health, this redundancy prevents process interruptions. The module also features watchdog timers and self-diagnostic functions that detect internal faults, automatically triggering an alarm or failover to a backup module if necessary, further enhancing system reliability.

YOKOGAWA PSCCM22AAN

4. Typical application scenarios

In a pharmaceutical manufacturing facility, the PSCCM22AAN controls the batch processing of drug formulations. It monitors temperature, pressure, and mixing speed via analog inputs, while digital outputs control heating elements, 搅拌器 motors, and valve actuators. Using HART communication, it collects diagnostic data from sensors to ensure measurement accuracy, which is essential for meeting strict regulatory requirements. The module’s flexible programming allows for easy adaptation to different drug recipes, with stored parameters enabling quick changeovers between production runs.

In a municipal wastewater treatment plant, the PSCCM22AAN manages the aeration process in biological treatment tanks. It receives dissolved oxygen (DO) levels from sensors via analog inputs and adjusts the speed of aeration blowers through analog outputs, optimizing oxygen transfer efficiency. Digital inputs monitor the status of blower motors and valves, while digital outputs trigger alarms if equipment malfunctions. The module communicates with a central SCADA system via Ethernet, providing real-time process data and enabling remote monitoring by plant operators.

In a pulp and paper mill, the PSCCM22AAN controls the consistency of pulp in the paper machine’s stock preparation system. It measures pulp concentration using a 4-20mA sensor and adjusts the flow of dilution water via a control valve, maintaining the precise consistency required for paper quality. The module’s HART capability allows it to track the valve’s position and health, alerting maintenance teams when calibration is needed. Its rugged design withstands the mill’s humid environment and electrical noise from large motors, ensuring reliable operation.

5. Related model recommendations

- PSCCM11AAN: A compact variant with 2 analog inputs, 1 analog output, and 4 digital I/O points, suitable for smaller-scale process control applications where the PSCCM22AAN‘s full I/O capacity is unnecessary.

- PSCCM33AAN: An expanded version with 8 analog inputs, 4 analog outputs, and 16 digital I/O points, ideal for more complex processes requiring additional monitoring and control points.

- CP401-10: The PLC that can coordinate multiple PSCCM22AANmodules in a distributed control system, providing centralized oversight of interconnected processes in a large plant.

- ISC40G-TF-T1-05: The industrial Ethernet switch that connects the PSCCM22AANto the plant’s network, enabling data transmission to SCADA systems and HMI panels.

- F3PU20-0N: The HMI panel that pairs with the PSCCM22AAN, allowing operators to monitor process variables, adjust setpoints, and view alarm statuses in real time.

- PS24-2A-R: A redundant 24V DC power supply that ensures reliable power to the PSCCM22AAN, complementing the module’s redundant input capability for critical applications.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the PSCCM22AAN, ensure the mounting location is in a control cabinet with ambient temperature between 0°C and 60°C, protected from dust, moisture, and excessive vibration. Prepare tools including a torque screwdriver (0.5-1.0Nm), wire strippers, and a multimeter.

Verify the power supply is 24V DC (18-30V range) and connect redundant power sources if required, ensuring correct polarity to prevent damage. Use shielded twisted-pair cables for analog signals, with the shield grounded at the sensor end to minimize electromagnetic interference. For digital I/O connections, use 18-22 AWG wires, and label each connection clearly to match the corresponding field device.

Maintenance suggestions

Perform monthly visual inspections of the PSCCM22AAN to check for loose connections, corrosion, or signs of overheating. Clean the module’s surface with a dry cloth if dust accumulates, taking care not to disturb wiring. Calibrate analog input channels quarterly using a precision signal generator to maintain measurement accuracy, especially in applications with strict tolerance requirements.

Monitor the module’s status indicators daily—steady green power and run lights indicate normal operation, while flashing or red lights signal faults. Check event logs weekly via the configuration software to review alarms and diagnostic messages, addressing any recurring issues promptly. Backup the module’s configuration and program files monthly to facilitate quick recovery in case of memory loss.

When replacing the PSCCM22AAN, transfer the configuration from the backup to the new module to ensure identical operation. Use only YOKOGAWA-approved replacement parts, and follow proper ESD procedures during installation to prevent damage to sensitive components.

7. Service and guarantee commitment

YOKOGAWA provides a 5-year warranty for the PSCCM22AAN, reflecting confidence in its reliability for process control applications. Each module undergoes rigorous testing, including temperature cycling, humidity testing, and electrical noise immunity checks, to ensure compliance with industrial standards.

Our technical support team offers 24/7 assistance for installation, programming, and troubleshooting, with specialists experienced in process control applications. On-site support is available in major industrial regions, with a response time of 48 hours for non-critical issues. YOKOGAWA provides detailed programming manuals and application notes specific to the PSCCM22AAN, helping customers implement effective control strategies.

Training programs are available, covering module configuration, programming, and integration with other YOKOGAWA products (such as the CP401-10 PLC and ISC40G-TF-T1-05 switch). Extended warranty options and preventive maintenance services are also offered to ensure long-term performance and minimize downtime in critical applications.