Description

1. Detailed parameter table

| Parameter name | Parameter value |

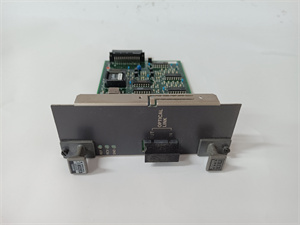

| Product model | PW481-50 |

| Manufacturer | YOKOGAWA |

| Product category | Industrial Redundant Power Supply |

| Output Voltage | 24V DC |

| Output Current | 50A (total), 25A per channel (dual output) |

| Input Voltage | 100-240V AC, 50/60Hz |

| Efficiency | ≥92% at full load |

| Regulation | ±0.5% (line), ±0.5% (load) |

| Operating Temperature Range | -10°C to 70°C |

| Protection Features | Overcurrent, overvoltage, short circuit, overtemperature protection |

| Dimensions | 160mm (W) x 130mm (H) x 220mm (D) |

| Weight | Approximately 3.5kg |

| Certification | IEC 61010-1, UL 508, CE, ATEX Zone 2 |

| Redundancy | 1+1 redundant configuration support |

YOKOGAWA PW481-50

2. Product introduction

The YOKOGAWA PW481-50 is a high-performance industrial redundant power supply designed to provide stable and reliable 24V DC power to critical automation equipment. As a key component in ensuring uninterrupted operation of industrial control systems, it delivers consistent power even in harsh industrial environments, making it an ideal companion to YOKOGAWA’s control modules like the PSCCM22AAN and PLCs such as the CP461-50.

This power supply offers a total output current of 50A (25A per channel in dual output mode), capable of powering multiple devices in a control cabinet. With an efficiency of ≥92% at full load, it minimizes energy loss and heat generation, contributing to energy efficiency in industrial settings. The PW481-50 supports 1+1 redundant configuration, ensuring that if one power supply unit fails, the other takes over seamlessly without interrupting power to connected equipment. Suitable for industries including oil and gas, power generation, and manufacturing, the YOKOGAWA PW481-50 provides a robust power solution to safeguard the operation of critical automation systems.

3. Core advantages and technical highlights

Dual-channel redundant design:

The PW481-50 features dual independent output channels, each capable of supplying 25A, which can be configured in parallel for redundancy. In a chemical plant control system, this means the PSCCM22AAN process control module and associated sensors can receive power from both channels—if one channel experiences a fault, the other continues to supply power without interruption. This redundancy eliminates a single point of failure in the power supply, a critical requirement for maintaining process stability in high-risk environments.

Precise voltage regulation:

With ±0.5% line and load regulation, the PW481-50 maintains a stable 24V DC output even when input voltage fluctuates or load changes occur. In a semiconductor manufacturing facility, where sensitive equipment like the PSCCM22AAN requires consistent power to ensure measurement accuracy, this stability prevents voltage spikes or drops that could affect process control precision. For example, it ensures the analog input channels of the PSCCM22AAN receive steady power, maintaining their 16-bit resolution accuracy for critical sensor measurements.

Wide temperature tolerance and ruggedness:

Operating reliably in -10°C to 70°C environments, the PW481-50 thrives in extreme conditions where standard power supplies would fail. In an outdoor renewable energy control cabinet, it withstands summer heat and winter cold while powering the CP461-50 PLC and ISC40G-TF-T1-05 switch. Its rugged construction includes conformal-coated circuit boards and resistance to vibration (5g peak, 10-2000Hz), making it suitable for mobile industrial equipment or offshore platforms.

Comprehensive protection mechanisms:

Equipped with overcurrent, overvoltage, short circuit, and overtemperature protection, the PW481-50 safeguards connected equipment from electrical faults. If a short circuit occurs in a field device connected to the PSCCM22AAN, the power supply immediately limits current to a safe level, preventing damage to both the module and the power supply itself. The overtemperature protection shuts down the unit if internal temperatures exceed safe limits, then automatically restarts once cooled—critical for preventing fire risks in enclosed control cabinets.

YOKOGAWA PW481-50

4. Typical application scenarios

In a large-scale petrochemical plant, the PW481-50 serves as the primary power source for a control cabinet housing multiple PSCCM22AAN modules, NFJT100-S10E firewalls, and HMI panels. Configured in redundant mode, it ensures continuous power to the process control system regulating reactor temperatures and pressure. During a sudden input voltage drop caused by a grid fluctuation, the power supply maintains stable output, preventing the PSCCM22AAN from losing calibration or control logic, which could lead to hazardous process conditions.

In a water treatment plant, the PW481-50 powers a distributed control system consisting of CP401-10 PLCs, flow sensors, and valve actuators. Its dual outputs allow separate powering of control logic (PLCs and PSCCM22AAN) and field devices (sensors and actuators), isolating potential faults. When a sensor wiring fault causes a short circuit, the power supply’s overcurrent protection limits current to the field device channel while maintaining power to the control logic, ensuring the PLC can still monitor and alert operators to the issue.

In a railway control system, the PW481-50 is installed in trackside cabinets to power signaling equipment, including safety relays and the NFPW444-50 security appliance. Its wide temperature range ensures operation in both hot desert and cold mountain regions, while vibration resistance withstands passing trains’ mechanical stress. The power supply’s high efficiency reduces heat generation, allowing it to operate in sealed cabinets without active cooling, lowering maintenance requirements in remote locations.

5. Related model recommendations

- PW481-25: A 25A variant (12.5A per channel) suitable for smaller control systems where the PW481-50‘s full capacity isn’t needed, ideal for powering a single PSCCM22AAN and associated devices.

- PW482-50: A dual-input version accepting both AC and DC inputs, providing flexibility for environments with unreliable AC grids, offering the same output capabilities as the PW481-50.

- PSCCM22AAN: The process control module that pairs with the PW481-50, relying on its stable power to maintain measurement and control accuracy in industrial processes.

- RBPW-01: A redundancy bypass module that works with the PW481-50in 1+1 configurations, enabling hot-swap of power supply units without interrupting power to connected equipment.

- ISC40G-TF-T1-05: The industrial Ethernet switch powered by the PW481-50, ensuring continuous network connectivity in automation systems.

- PW481-50-F: A fanless variant of the PW481-50for noise-sensitive environments, using conduction cooling to maintain operation in -10°C to 60°C ranges.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the PW481-50, ensure the mounting location in the control cabinet has at least 150mm clearance above and below for ventilation. The ambient temperature must remain within -10°C to 70°C, away from direct heat sources. Prepare tools including a torque screwdriver (3.0-4.0Nm), wire strippers, and a multimeter.

Verify the input voltage matches 100-240V AC and install a 16A circuit breaker for overcurrent protection. Use 10mm² cables for output connections to handle 50A current, ensuring proper termination with ferrules. For redundant configurations, connect two PW481-50 units to a redundancy module, with separate input power sources for maximum reliability. Ground the power supply using a 4mm² wire connected to the cabinet’s protective earth (PE) terminal.

Maintenance suggestions

Perform quarterly visual inspections of the PW481-50 to check for loose connections, dust accumulation, or bulging capacitors. Clean ventilation grilles with compressed air to maintain airflow—more frequently in dusty environments. Monitor output voltage monthly using a precision multimeter, ensuring it remains within 24V ±0.5%.

Check status indicators daily: a steady green LED indicates normal operation, while red LEDs signal faults (overtemperature, overvoltage, etc.). In redundant systems, verify both units are operational by temporarily disconnecting one and confirming the other maintains output. Replace air filters (if equipped) annually to prevent overheating.

If a fault occurs, consult the error code manual to identify the cause. Common issues like overcurrent often result from external wiring faults rather than internal failures. When replacing the PW481-50, use the redundancy module to hot-swap the unit without powering down connected equipment like the PSCCM22AAN, minimizing downtime.

7. Service and guarantee commitment

YOKOGAWA provides a 5-year warranty for the PW481-50, reflecting confidence in its reliability as a critical power component. Each unit undergoes rigorous testing, including temperature cycling, voltage surge immunity, and long-term load testing, to ensure compliance with industrial standards.

Our technical support team offers 24/7 assistance for installation, configuration, and troubleshooting, with specialists experienced in power supply redundancy systems. On-site support is available in major industrial regions, with a 48-hour response time for non-critical issues. YOKOGAWA provides detailed wiring diagrams and redundancy configuration guides specific to the PW481-50, helping customers integrate it effectively with products like the PSCCM22AAN and CP461-50.

Training programs cover power supply maintenance and redundant system design, ensuring customers maximize uptime. Extended warranty options and preventive maintenance services are available, including periodic health checks to identify potential issues before they cause failures, ensuring long-term power reliability for critical automation systems.