Description

1. Detailed parameter table

| Parameter name | Parameter value |

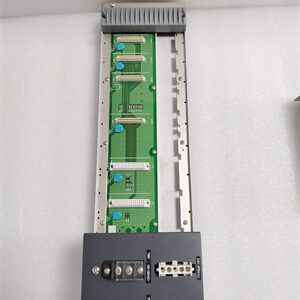

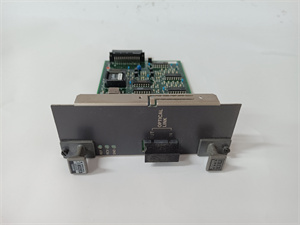

| Product model | PW482-10 S2 |

| Manufacturer | YOKOGAWA |

| Product category | Industrial Dual-Input Redundant Power Supply |

| Output Voltage | 24V DC |

| Output Current | 10A (total), 5A per channel (dual output) |

| Input Voltage | 100-240V AC / 24-60V DC (dual-input support) |

| Efficiency | ≥90% at full load |

| Regulation | ±0.8% (line), ±0.8% (load) |

| Operating Temperature Range | -20°C to 75°C |

| Protection Features | Overcurrent, overvoltage, short circuit, overtemperature, reverse polarity protection |

| Dimensions | 120mm (W) x 100mm (H) x 180mm (D) |

| Weight | Approximately 2.2kg |

| Certification | IEC 61010-1, UL 508, CE, ATEX Zone 2 |

| Redundancy | 1+1 redundant configuration support |

Yokogawa PW482-10 S2

2. Product introduction

The YOKOGAWA PW482-10 S2 is a compact industrial dual-input redundant power supply engineered to deliver stable 24V DC power to small to medium-sized automation systems. Building on the reliability of the PW481 series, it stands out with its versatile dual-input design, accepting both AC and DC power sources, making it ideal for environments where power supply stability is unpredictable or where backup DC power is available.

With a total output current of 10A (5A per channel in dual output mode), this power supply is perfectly suited to power devices like the PSCCM22AAN process control module, small PLCs, and industrial switches such as the ISC40G-TF-T1-05. Its 1+1 redundancy support ensures that critical equipment remains powered even if one power supply unit fails. The PW482-10 S2 operates efficiently in extreme temperatures ranging from -20°C to 75°C, making it suitable for industries such as renewable energy, transportation, and remote industrial sites. As a robust power solution, it ensures uninterrupted operation of essential automation components, enhancing system reliability and minimizing downtime.

3. Core advantages and technical highlights

Dual-input flexibility:

Unlike the PW481-50, the PW482-10 S2 accepts both 100-240V AC and 24-60V DC inputs, providing unparalleled flexibility. In a remote solar power plant, this means the power supply can operate on AC from the grid when available and seamlessly switch to DC from battery storage during power outages, ensuring continuous power to the PSCCM22AAN modules monitoring solar panel performance. This dual-input capability eliminates the need for external converters, simplifying system design and reducing potential points of failure.

Enhanced cold temperature operation:

With an operating range down to -20°C (wider than the PW481-50’s -10°C), the PW482-10 S2 excels in cold environments. In a polar research station’s control system, it reliably powers temperature sensors and data loggers (connected via the ISC40G-TF-T1-05 switch) even in freezing conditions, where standard power supplies would struggle to start or maintain output. Its low-temperature startup capability ensures it activates smoothly without voltage drops, critical for maintaining data collection in extreme climates.

Compact design with high power density:

The PW482-10 S2‘s compact dimensions (120mm x 100mm x 180mm) make it ideal for space-constrained control cabinets. In a railway locomotive’s on-board control system, it fits easily alongside other components, powering safety relays and communication devices without occupying excessive space. Despite its small size, it delivers a high power density of 0.4W/cm³, ensuring efficient power delivery without sacrificing performance.

Comprehensive protection with reverse polarity tolerance:

In addition to the standard protection features of the PW481-50, the PW482-10 S2 includes reverse polarity protection on its DC input. This is particularly valuable in field installations where wiring mistakes are possible—for example, in a construction site’s temporary control system, accidental reversal of DC power connections won’t damage the supply or connected equipment like the PSCCM22AAN, saving repair costs and reducing downtime.

Yokogawa PW482-10 S2

4. Typical application scenarios

In a wind turbine control system, the PW482-10 S2 powers the pitch control mechanism’s sensors and actuators. It operates on AC from the turbine’s generator during normal operation and switches to DC from a backup battery when the turbine is shut down for maintenance, ensuring the PSCCM22AAN module continues monitoring critical parameters like rotor speed and vibration. The power supply’s vibration resistance (10g peak, 10-2000Hz) withstands the turbine’s mechanical stress, maintaining reliable operation.

In a mobile military communication vehicle, the PW482-10 S2 provides power to encryption devices and network equipment (including the NFJT100-S10E firewall). Its dual-input design allows it to run on the vehicle’s 24V DC battery system when moving and switch to AC from a generator when stationary, ensuring uninterrupted communication. The compact size fits the limited space in the vehicle, while its rugged construction withstands the shocks and vibrations of off-road travel.

In a remote water pumping station, the PW482-10 S2 powers the control system consisting of a small PLC, flow meters, and valve controllers. It uses solar-charged batteries (DC input) as the primary power source and switches to grid AC during extended cloudy periods. The power supply’s wide temperature range ensures it operates in both hot daytime and cold nighttime conditions, while its redundancy feature prevents pump shutdowns due to power supply failure, ensuring continuous water supply to remote communities.

5. Related model recommendations

- PW481-50: A higher-capacity (50A) power supply for larger systems, where the PW482-10 S2‘s 10A output is insufficient, suitable for powering multiple racks of equipment.

- PW482-20 S2: A 20A variant of the PW482-10 S2, offering the same dual-input flexibility but with higher output for medium-sized systems.

- PSCCM22AAN: The process control module that pairs with the PW482-10 S2, benefiting from its stable power output for accurate sensor measurements and control.

- RBPW-01: The redundancy bypass module compatible with the PW482-10 S2, enabling hot-swap in redundant configurations to minimize downtime during maintenance.

- ISC40G-TF-T1-05: The industrial Ethernet switch powered by the PW482-10 S2, ensuring reliable network connectivity in small to medium-sized industrial networks.

- BMS12-5A: A battery management system that works with the PW482-10 S2‘s DC input, optimizing battery charging and extending lifespan in solar or backup power systems.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the PW482-10 S2, ensure the mounting location has at least 100mm clearance for ventilation. The ambient temperature should be within -20°C to 75°C, away from direct heat sources. Prepare tools including a torque screwdriver (2.0-3.0Nm), wire strippers, and a multimeter.

For AC input, verify the voltage is 100-240V AC and install a 5A circuit breaker. For DC input, ensure the voltage is 24-60V DC and use a 3A breaker. Use 2.5mm² cables for output connections to handle 10A current. In redundant configurations, connect two PW482-10 S2 units to the RBPW-01 module, with separate AC and DC sources for maximum reliability. Ground the unit using a 2.5mm² wire connected to the cabinet’s PE terminal.

Maintenance suggestions

Perform quarterly visual inspections of the PW482-10 S2 to check for loose connections, dust, or corrosion. Clean ventilation openings with compressed air to maintain cooling efficiency. Monitor output voltage monthly to ensure it remains within 24V ±0.8% using a precision multimeter.

Check status indicators weekly: a green LED indicates normal operation, while red LEDs signal faults (e.g., overcurrent, overtemperature). Test input switching by disconnecting the primary input (AC or DC) and confirming the unit continues operating on the secondary input. Replace air filters (if equipped) annually, or more frequently in dusty environments.

If a fault occurs, first check external wiring and loads (e.g., short circuits in PSCCM22AAN connections) before assuming a power supply failure. In redundant setups, use the RBPW-01 module to hot-swap the PW482-10 S2 without powering down connected equipment, minimizing disruption.

7. Service and guarantee commitment

YOKOGAWA provides a 5-year warranty for the PW482-10 S2, reflecting confidence in its durability and performance. Each unit undergoes rigorous testing, including temperature cycling (from -20°C to 75°C), vibration testing, and input voltage transient testing, ensuring compliance with industrial standards.

Our technical support team offers 24/7 assistance for installation, configuration, and troubleshooting, with specialists experienced in dual-input power systems. On-site support is available in major regions with a 48-hour response time for non-critical issues. YOKOGAWA provides detailed guides on configuring the PW482-10 S2 with both AC and DC inputs, as well as integrating it with products like the PSCCM22AAN and ISC40G-TF-T1-05.

Training programs cover redundant configuration, input switching, and maintenance best practices, helping customers maximize the reliability of their power systems. Extended warranty options and preventive maintenance services are available, including annual health checks to ensure the PW482-10 S2 continues to operate at peak performance.