Description

1. Detailed parameter table

| Parameter name | Parameter value |

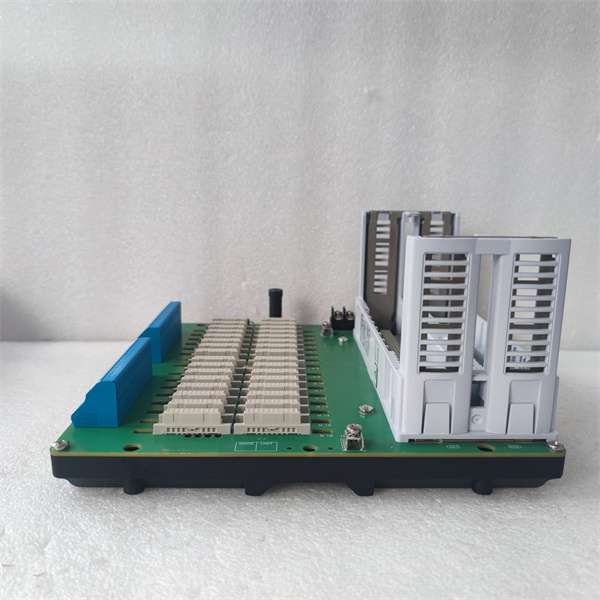

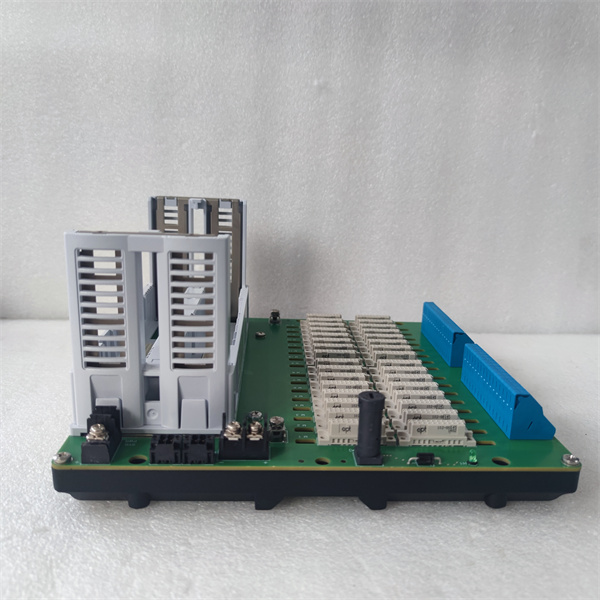

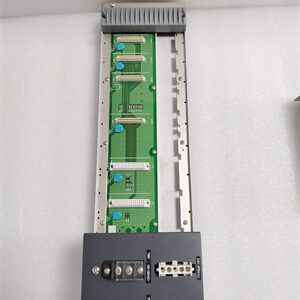

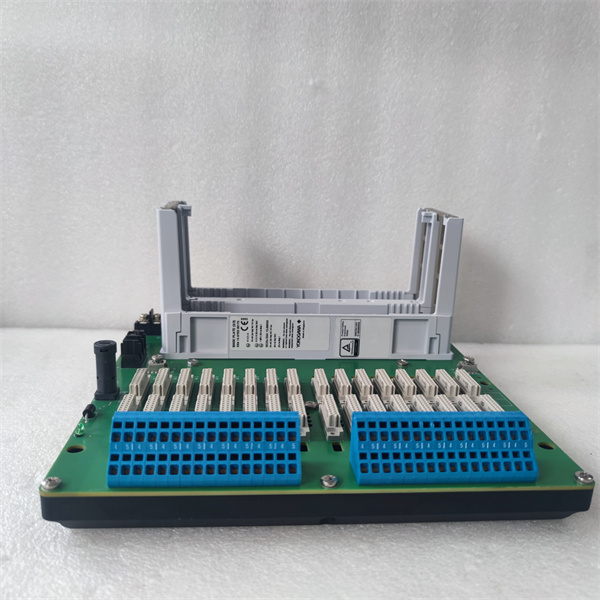

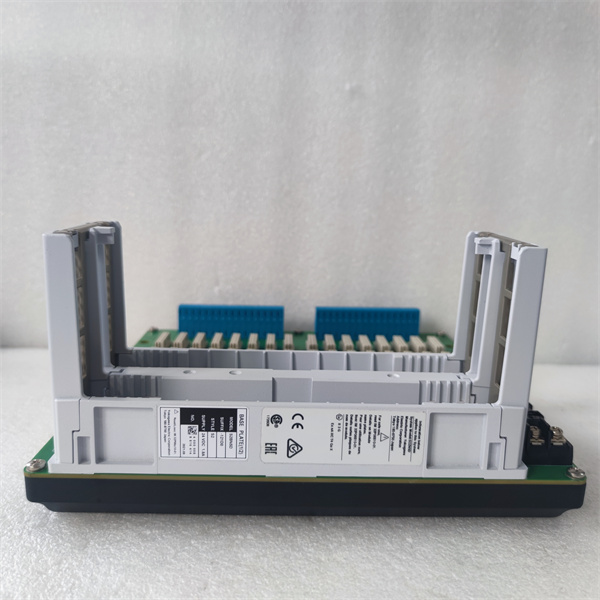

| Product model | S2BN5D-121 DO |

| Manufacturer | YOKOGAWA |

| Product category | Industrial Digital Output Module |

| Number of Output Channels | 16 channels |

| Output Type | Relay output |

| Rated Load Voltage | 24V DC, 100-240V AC |

| Maximum Load Current per Channel | 2A |

| Maximum Total Load Current | 10A |

| Response Time | ≤10ms (turn on/off) |

| Isolation | Channel-to-channel: 2.5kV AC (1min); Channel-to-backplane: 5kV AC (1min) |

| Operating Temperature Range | -10°C to 60°C |

| Power Consumption | ≤5W (without load) |

| Dimensions | 30mm (W) x 100mm (H) x 160mm (D) |

| Weight | Approximately 0.3kg |

| Certification | IEC 61131-2, UL 508, CE, ATEX Zone 2 |

YOKOGAWA S2BN5D-121 DO

2. Product introduction

The YOKOGAWA S2BN5D-121 DO is a high-performance industrial digital output module designed to provide reliable switching control for external devices in automation systems. Unlike the high-power PW702 power supply, this module focuses on precise and safe signal transmission, acting as a critical interface between control systems (such as the CP461-50 PLC) and field equipment like valves, motors, and alarms.

Featuring 16 relay output channels, the S2BN5D-121 DO can independently control multiple devices, supporting both 24V DC and 100-240V AC load voltages to accommodate diverse industrial equipment. With a maximum load current of 2A per channel and 10A in total, it balances flexibility and power handling capability. The module’s robust isolation design ensures immunity to electromagnetic interference, making it suitable for industries such as chemical processing, food and beverage, and automotive manufacturing. As a key component in industrial control loops, the YOKOGAWA S2BN5D-121 DO ensures accurate execution of control commands, enhancing the overall reliability and efficiency of automation systems.

3. Core advantages and technical highlights

Multi-voltage compatibility:

Unlike modules limited to a single voltage type, the S2BN5D-121 DO supports both 24V DC and 100-240V AC loads, eliminating the need for separate modules for different equipment. In a food processing plant, it can control 24V DC conveyor motors and 230V AC heating elements through the same module, simplifying cabinet design and reducing wiring complexity. This versatility also allows easy upgrades or modifications to the system without replacing the output module.

Strong isolation and anti-interference:

With 2.5kV AC channel-to-channel isolation and 5kV AC channel-to-backplane isolation, the S2BN5D-121 DO effectively blocks electromagnetic interference (EMI) from high-power devices. In a welding workshop where the PW702 power supply handles large currents, the module ensures that control signals sent to robotic welders remain stable, preventing false triggering or unexpected shutdowns caused by EMI. This isolation also protects the central PLC (like the CP461-50) from voltage spikes generated by inductive loads such as solenoid valves.

Reliable relay output with status feedback:

Each relay output of the S2BN5D-121 DO provides built-in contact status feedback, allowing the control system to verify if a command has been executed correctly. In a water treatment plant, when the module sends a signal to open a drainage valve, the feedback confirms whether the valve actually opened—critical for preventing overflow incidents. The relays have a mechanical lifespan of 100,000 operations, ensuring long-term reliability in frequent cycling applications.

Compact design with high channel density:

Measuring just 30mm in width, the S2BN5D-121 DO offers 16 channels in a slim form factor, maximizing space utilization in control cabinets. In a space-constrained offshore platform control system, it fits alongside the ISC40G-TF-T1-05 switch and PW702 power supply, providing ample output channels without increasing cabinet size. This high density reduces the number of modules needed, lowering overall system cost.

YOKOGAWA S2BN5D-121 DO

4. Typical application scenarios

In a chemical plant’s reactor control system, the S2BN5D-121 DO acts as the interface between the CP461-50 PLC and critical valves. It sends signals to open/close inlet and outlet valves, with feedback confirming valve positions to ensure the reactor operates within safe parameters. During a batch reaction, the module sequentially activates different valves according to the PLC’s program, precisely controlling the addition of raw materials and the removal of products. The module’s resistance to chemical corrosion (via conformal coating) ensures reliable operation in the plant’s harsh environment.

In an automotive assembly line, the S2BN5D-121 DO controls various pneumatic tools, part conveyors, and safety barriers. It receives commands from the PLC to activate riveting machines at specific times and triggers safety doors to open/close as vehicles move along the line. The status feedback feature alerts operators if a tool fails to activate, allowing immediate intervention to prevent production delays. The module’s compact size fits easily in the control cabinets alongside the NFPW444-50 security appliance, saving valuable space.

In a smart building’s HVAC system, the S2BN5D-121 DO manages dampers, fans, and heating elements. It works with temperature sensors and the building management PLC to adjust airflow and heating based on occupancy and ambient conditions. For example, it activates 24V DC fans in conference rooms when CO₂ levels rise and switches on 230V AC heaters in cold zones—all through the same module. The relay status feedback ensures the system can diagnose issues like a stuck damper, maintaining optimal indoor comfort.

5. Related model recommendations

- S2BN5A-121 AO: YOKOGAWA’s analog output module, complementary to the S2BN5D-121 DO, for applications requiring variable control (e.g., valve positioning) alongside on/off control.

- S2BN5D-081 DO: An 8-channel variant of the S2BN5D-121 DOfor smaller systems where fewer output channels are needed, offering the same isolation and reliability.

- CP461-50: The high-performance PLC that pairs with the S2BN5D-121 DO, sending control commands and processing feedback signals to coordinate complex industrial processes.

- PW702: The industrial power supply that provides stable 24V DC to the S2BN5D-121 DOand connected field devices, ensuring consistent operation.

- F3PU50-0N: The HMI panel that displays the status of the S2BN5D-121 DO‘s outputs, allowing operators to monitor and manually override controls if necessary.

- S2BN5D-TB121: A terminal block accessory for the S2BN5D-121 DO, simplifying wiring and providing surge protection for connected devices.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the S2BN5D-121 DO, ensure the mounting rail is properly secured in a control cabinet with ambient temperature between -10°C and 60°C. Prepare tools including a torque screwdriver (0.5-1.5Nm), wire strippers, and a multimeter.

Verify that the backplane power supply (typically 5V DC from the PLC rack) is within specifications. Use 16-22 AWG wires for load connections, with separate wiring for power and signal lines to minimize interference. Connect each output channel to its load, ensuring proper polarity for DC loads, and install appropriate fuses (2A per channel) in the load circuit. Ground the module’s protective earth terminal to the cabinet’s PE busbar.

Maintenance suggestions

Perform quarterly visual inspections of the S2BN5D-121 DO to check for loose connections, dust accumulation, or signs of overheating. Clean the module’s surface with a dry, lint-free cloth if needed, taking care not to disturb wiring. Test each output channel monthly by sending commands from the PLC and verifying load activation and status feedback—this can be automated using diagnostic software.

Monitor the module’s status LEDs: a steady green light indicates normal operation, while red lights signal faults (e.g., overcurrent, relay failure). If a channel fails, first check the connected load and wiring for shorts or overloads before replacing the module. When replacing the S2BN5D-121 DO, transfer the wiring to the new module and verify all channels function correctly before returning the system to normal operation.

Keep spare modules in a dry, static-free environment, preferably in anti-static packaging. Document the wiring configuration and channel assignments to facilitate quick replacement and troubleshooting.

7. Service and guarantee commitment

YOKOGAWA provides a 5-year warranty for the S2BN5D-121 DO, reflecting confidence in its reliability as a critical control component. Each module undergoes rigorous testing, including temperature cycling, vibration testing, and isolation resistance verification, ensuring compliance with industrial standards.

Our technical support team offers 24/7 assistance for installation, configuration, and troubleshooting, with specialists experienced in digital output systems. On-site support is available in major industrial regions with a 48-hour response time for non-critical issues. YOKOGAWA provides detailed wiring diagrams and integration guides specific to the S2BN5D-121 DO, helping customers connect it seamlessly with PLCs like the CP461-50 and field equipment.

Training programs cover digital output module maintenance and system diagnostics, ensuring customers maximize uptime. Extended warranty options and preventive maintenance services are available, including periodic function testing to identify potential issues before they cause failures, ensuring long-term reliability in industrial control systems.