Description

Product Overview

The YOKOGAWA AAI143 – S50 is a high-performance analog input module, belonging to Yokogawa’s renowned lineup of industrial process control components. As an upgraded and expanded version in the AAI series, it is designed to accurately collect and process multiple analog signals from industrial sensors, serving as a critical data acquisition link in complex industrial control systems. Developed by Yokogawa, a global leader in industrial automation, this module inherits the excellent performance of the series, ensuring reliable, precise, and efficient data transmission to upper-level control platforms, thus enhancing the monitoring and control capabilities of industrial processes across various sectors.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

AAI143 – S50

|

|

Manufacturer

|

YOKOGAWA

|

|

Product Type

|

Analog Input Module

|

|

Input Type

|

Supports thermocouples (e.g., J, K, T, E, R, S, B), RTDs (e.g., Pt100, Pt1000), and 4 – 20 mA current signals

|

|

Number of Channels

|

8 channels

|

|

Accuracy

|

For thermocouples: ±0.1% of reading + 0.3 °C; For RTDs: ±0.05% of reading + 0.1 °C; For 4 – 20 mA: ±0.05% of span

|

|

Operating Voltage

|

24 V DC

|

|

Operating Temperature Range

|

0 °C – 60 °C

|

|

Storage Temperature Range

|

– 20 °C – 70 °C

|

|

Isolation

|

Channel – to – channel: 250 V AC; Channel – to – backplane: 500 V AC

|

|

Dimensions

|

(W x H x D) 30 mm x 120 mm x 150 mm

|

|

Weight

|

0.3 kg

|

|

Protection Level

|

IP20

|

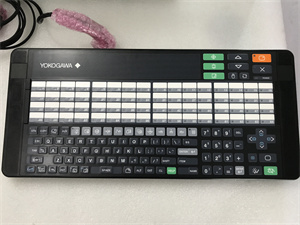

YOKOGAWA AAI143-S50

Main Features and Advantages

Expanded Channel Capacity

The YOKOGAWA AAI143 – S50 features 8 channels, doubling the channel count of the AAI141 – H50/K4A00. This expanded capacity makes it ideal for large – scale industrial applications that require simultaneous data collection from multiple sensors. In a large chemical plant, for example, it can collect temperature signals from 8 different reactors or pressure signals from 8 pipelines at the same time, eliminating the need for multiple 4 – channel modules. This not only simplifies the system structure but also reduces installation space and overall costs.

Consistent High Accuracy

Like its counterpart AAI141 – H50/K4A00, the AAI143 – S50 maintains ultra – high measurement accuracy. Equipped with advanced signal processing technology, it can accurately capture even tiny changes in process parameters. In pharmaceutical production, where strict control of reaction conditions is crucial, this module can precisely measure the temperature and pressure in multiple reactors, providing reliable data support for precise process control and ensuring the quality and consistency of pharmaceutical products.

Strong Anti – interference and Stability

The YOKOGAWA AAI143 – S50 adopts the same advanced isolation technology as the AAI141 – H50/K4A00, with 250 V AC isolation between channels and 500 V AC isolation between channels and the backplane. This effectively prevents cross – interference between channels and interference from the backplane. Additionally, it is equipped with high – performance filters and shielding measures to resist electromagnetic interference from the surrounding environment. In factories with numerous high – power electrical equipment, this module can still collect stable and accurate signals, ensuring the reliability of the entire control system.

Seamless Integration with DCS Systems

Designed to be fully compatible with Yokogawa’s distributed control systems (DCS) such as CENTUM VP, the AAI143 – S50 can seamlessly integrate into existing control architectures. It enables real – time data transmission to the central control room, allowing operators to monitor multiple process parameters simultaneously. In a large – scale petrochemical complex, this module can upload data from 8 different process points to the CENTUM VP system in real – time, facilitating centralized monitoring and timely adjustments, thus improving the overall operational efficiency of the plant.

YOKOGAWA AAI143-S50

Application Field

In the oil and gas industry, the YOKOGAWA AAI143 – S50 is widely used in large – scale refineries and oil fields. It can collect temperature, pressure, and flow signals from multiple pipelines and equipment in the distillation, hydrogenation, and other units, providing comprehensive data for process optimization and safety monitoring. In offshore oil platforms, its stable performance ensures reliable data acquisition even in harsh marine environments.

For the power generation sector, this module is applied in thermal power plants and nuclear power plants. In thermal power plants, it can measure parameters such as the temperature of boiler water, steam pressure, and turbine bearing temperature in multiple positions, helping to ensure the safe and efficient operation of the power generation equipment. In nuclear power plants, it plays a key role in monitoring the parameters of the reactor cooling system and auxiliary systems, ensuring the stable operation of the entire nuclear power plant.

In the chemical industry, the AAI143 – S50 is used in large – scale chemical production lines. It can collect the temperature, pressure, and concentration signals of reactants in multiple reactors and pipelines, enabling precise control of the chemical reaction process and ensuring product quality. Its 8 – channel design is particularly suitable for integrated chemical plants where multiple process parameters need to be monitored simultaneously.

Related Products

- YOKOGAWA AAI141 – H50/K4A00: As a 4 – channel analog input module in the same series, it is suitable for small – scale applications with fewer signal collection requirements. The AAI143 – S50, with its 8 – channel capacity, is a better choice for large – scale systems, while both share the same high accuracy and reliability.

- YOKOGAWA AAO143 – S50: An analog output module that matches the AAI143 – S50. While the AAI143 – S50 is responsible for collecting analog signals, the AAO143 – S50 outputs analog signals to control valves, frequency converters, and other actuators, forming a complete closed – loop control system.

- YOKOGAWA CENTUM VP DCS: This advanced distributed control system is perfectly compatible with the AAI143 – S50. The module can be easily integrated into the system, enabling centralized management and processing of the collected data, and supporting functions such as process visualization and alarm management.

- YOKOGAWA CA700 Calibration Tool: Used for regular calibration of the AAI143 – S50, this tool ensures that the module maintains high measurement accuracy during long – term operation, thus guaranteeing the reliability of the process control system.

Installation and Maintenance

Pre – installation preparation: Before installing the YOKOGAWA AAI143 – S50, carefully read the installation manual provided by Yokogawa. Ensure that the 24 V DC power supply is stable and meets the requirements. Check that the mounting rack and backplane are compatible with the module. Prepare necessary tools such as screwdrivers and wire strippers, and ensure that the connecting cables are of appropriate specifications. Select an installation location away from strong electromagnetic interference, high temperature, and high humidity areas, within the specified operating temperature range.

Installation steps: Insert the module into the corresponding slot of the mounting rack and fix it with screws to ensure firm installation. Connect the field sensor signals to the 8 channels of the module according to the wiring diagram, paying attention to the correct polarity and wiring specifications for different signal types (e.g., using compensation wires for thermocouples). Connect the 24 V DC power supply to the module’s power interface. After wiring, conduct a comprehensive inspection to ensure all connections are correct and secure.

Maintenance recommendations: Regularly inspect the YOKOGAWA AAI143 – S50 for physical damage, loose connections, or abnormal heating. Clean the module’s surface with a dry, soft cloth to remove dust and debris, especially in dusty environments. Perform regular calibration (usually once a year) using professional tools like the Yokogawa CA700 to maintain measurement accuracy. Utilize the diagnostic functions of the DCS system to monitor the module’s operating status in real – time, checking for communication errors and signal abnormalities. If faults are found, refer to the troubleshooting guide in the product manual or contact Yokogawa’s technical support team. When replacing the module, follow the correct procedures to avoid damaging the backplane or other components.

Product Guarantee

YOKOGAWA ensures the high quality and reliability of the AAI143 – S50. The module undergoes rigorous testing and strict quality control during manufacturing to meet international industry standards. It comes with a 3 – year warranty period. During the warranty period, if there are defects caused by faulty materials or workmanship, Yokogawa will provide free repair or replacement services. In addition, Yokogawa’s professional technical support team offers installation guidance, debugging assistance, and troubleshooting services. The company’s global service network ensures timely support for users worldwide, reflecting Yokogawa’s confidence in the product and its commitment to customer satisfaction.