Description

1. Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

CP401-10

|

|

Manufacturer

|

YOKOGAWA

|

|

Product category

|

Programmable Logic Controller (PLC)

|

|

Processing Speed

|

0.1μs per basic instruction

|

|

Program Memory

|

1MB (expandable up to 4MB)

|

|

I/O Points

|

256 points (expandable up to 8192 points)

|

|

Communication Interfaces

|

Ethernet (10/100Mbps), RS-232C, RS-485

|

|

Supported Protocols

|

Modbus RTU/TCP, Ethernet/IP, Profibus DP

|

|

Operating Temperature Range

|

0°C to 60°C

|

|

Power Supply

|

100-240V AC, 50/60Hz

|

|

Dimensions

|

140mm (W) x 100mm (H) x 180mm (D)

|

|

Weight

|

Approximately 0.8kg

|

|

Certification

|

IEC 61131-2, UL 508, CE

|

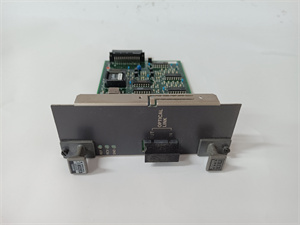

YOKOGAWA CP401-10

2. Product introduction

The YOKOGAWA CP401-10 is a compact yet powerful programmable logic controller designed for medium to large-scale industrial automation applications. As part of YOKOGAWA’s CP series, it combines high processing performance with extensive I/O scalability, making it suitable for controlling complex manufacturing processes and machinery.

This PLC features a processing speed of 0.1μs per basic instruction, enabling rapid execution of control logic even for sophisticated automation sequences. The CP401-10 supports multiple programming languages including ladder logic, structured text, and function block diagrams, allowing engineers to choose the most efficient method for their application. Its rich communication capabilities facilitate seamless integration with HMI panels, SCADA systems, and other industrial devices, providing centralized monitoring and control. Ideal for industries such as automotive manufacturing, food processing, and water treatment, the YOKOGAWA CP401-10 delivers reliable and precise control to optimize production efficiency and ensure consistent product quality.

3. Core advantages and technical highlights

High-speed processing capability:

With a processing speed of 0.1μs per basic instruction, the CP401-10 excels at handling complex control logic with minimal latency. In high-speed packaging lines, this allows the PLC to process sensor inputs and generate output commands in real-time, ensuring precise synchronization of multiple machines. For example, in a bottling plant, the PLC can coordinate bottle filling, capping, and labeling operations with microsecond accuracy, reducing product waste and maximizing throughput.

Scalable I/O architecture:

The CP401-10 supports up to 8192 I/O points through expansion modules, providing exceptional scalability for growing automation systems. In a automotive assembly plant, this flexibility allows the PLC to control everything from conveyor belts and robotic arms to quality inspection cameras—all through a single control platform. As production lines expand, additional I/O modules can be added without replacing the main controller, reducing upgrade costs and minimizing downtime.

Multi-protocol communication:

Equipped with Ethernet, RS-232C, and RS-485 interfaces, the CP401-10 supports a wide range of industrial protocols including Modbus and Ethernet/IP. This enables seamless communication with diverse devices such as variable frequency drives (like the AVR10D-Q22020 servo drive), HMI panels, and barcode scanners. In a smart factory environment, this connectivity allows the PLC to share production data with enterprise resource planning (ERP) systems, enabling data-driven decision making and predictive maintenance.

Redundant design options:

The CP401-10 can be configured with redundant power supplies and communication modules, ensuring uninterrupted operation even in the event of a component failure. In critical applications such as chemical processing plants, this redundancy prevents production shutdowns due to equipment malfunctions, protecting against costly downtime and potential safety hazards. The PLC’s self-diagnostic capabilities continuously monitor system health, providing early warning of potential issues before they escalate.

YOKOGAWA CP401-10

4. Typical application scenarios

In automotive manufacturing, the CP401-10 controls the entire assembly line of a car body shop. It coordinates the operation of robotic welding arms, material handling systems, and quality control sensors. Using its high-speed processing, the PLC ensures precise timing of welding operations—each weld must be applied with the correct pressure and duration to meet safety standards. The PLC’s Ethernet/IP interface connects to an HMI system, allowing operators to monitor production metrics and adjust parameters in real-time, optimizing cycle times and reducing defects.

In water treatment facilities, the CP401-10 manages filtration systems, chemical dosing pumps, and distribution networks. It processes inputs from flow meters, pH sensors, and level transmitters to regulate treatment processes, ensuring water quality meets regulatory standards. The PLC’s redundant design provides failsafe operation—if a primary communication module fails, a backup module automatically takes over, preventing interruptions in water supply. Through Modbus communication, the PLC shares data with a SCADA system, enabling remote monitoring of the entire treatment plant.

In food and beverage processing, the CP401-10 controls cooking, cooling, and packaging processes with strict adherence to recipe parameters. It maintains precise temperature control during pasteurization, ensuring food safety while preserving product quality. The PLC’s data logging capabilities record critical process variables such as temperature and pressure, providing traceability for regulatory compliance. Its ability to communicate with barcode scanners allows for batch tracking, enabling quick recalls if quality issues arise.

5. Related model recommendations

- CP401-05: A smaller variant of the CP401-10 with 0.2μs processing speed and up to 4096 I/O points, ideal for medium-scale applications where the full capabilities of the CP401-10 are not required.

- CP601-10: A high-performance PLC with 0.05μs processing speed and support for up to 16,384 I/O points, providing an upgrade path from the CP401-10 for large-scale industrial complexes.

- F3PU20-0N: YOKOGAWA’s advanced HMI panel that pairs with the CP401-10, offering intuitive operator control and real-time visualization of process data.

- AVR10D-Q22020: A servo drive that integrates seamlessly with the CP401-10 for precision motion control applications, receiving control signals via Ethernet/IP.

- ANB10D-425/CU2T: A digital input module that expands the CP401-10‘s input capabilities, providing reliable detection of sensor signals in harsh industrial environments.

- CP401-10-R: A ruggedized version of the CP401-10 with extended temperature range (-20°C to 70°C) and enhanced vibration resistance, designed for outdoor or mobile machinery applications.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the CP401-10, ensure the mounting location provides adequate ventilation with at least 150mm clearance around the PLC. The ambient temperature must remain within 0°C to 60°C, and the area should be protected from dust, moisture, and corrosive gases. Prepare tools including a torque screwdriver (0.5-1.0Nm), wire strippers, and a network cable tester.

Verify the power supply matches the 100-240V AC specification and install a dedicated 2A circuit breaker for overcurrent protection. Use shielded twisted-pair cables for communication interfaces, grounding the shield at both ends to minimize electromagnetic interference. When mounting the PLC on a DIN rail, ensure it is securely fastened to prevent vibration-induced damage to internal components.

Maintenance suggestions

Perform monthly visual inspections of the CP401-10 to check for loose connections, dust accumulation, or signs of overheating. Clean ventilation slots using compressed air quarterly to maintain proper cooling—more frequently in dusty environments. Backup the program and configuration data weekly to prevent loss in case of memory failure.

Monitor the PLC’s status indicators daily to check for error codes or abnormal operation. Use YOKOGAWA’s programming software to run diagnostic tests quarterly, checking for communication errors and I/O module malfunctions. If a fault occurs, refer to the error code manual for troubleshooting guidance—common issues like communication failures often require checking cable connections or network settings.

Replace the lithium backup battery every 3-5 years to prevent program loss during power outages. When replacing the CP401-10, transfer the program and configuration data to the new unit using the backup function, ensuring identical operation. Use only YOKOGAWA-approved replacement parts to maintain system reliability and warranty coverage.

7. Service and guarantee commitment

YOKOGAWA provides a 5-year warranty for the CP401-10, reflecting confidence in its durability and reliability for critical automation applications. Each PLC undergoes rigorous testing including temperature cycling, vibration testing, and electrical noise immunity checks to ensure compliance with international standards.

Our global technical support team offers 24/7 assistance for programming, troubleshooting, and system optimization. On-site service is available in major industrial regions, with response times within 48 hours for critical failures. YOKOGAWA provides comprehensive training programs on CP401-10 programming and maintenance, helping customers maximize the PLC’s capabilities and minimize downtime. Additionally, we offer extended warranty options and preventive maintenance services to ensure long-term performance and peace of mind for our customers.