Description

1. Detailed parameter table

| Parameter name | Parameter value |

| Product model | PW702 |

| Manufacturer | YOKOGAWA |

| Product category | Industrial High-Power Switching Power Supply |

| Output Voltage | 24V DC (adjustable 22-28V) |

| Output Current | 40A (total), 20A per channel (dual output) |

| Input Voltage | 85-264V AC, 120-370V DC |

| Efficiency | ≥94% at full load |

| Regulation | ±0.3% (line), ±0.5% (load) |

| Operating Temperature Range | -25°C to 75°C |

| Protection Features | Overcurrent, overvoltage, short circuit, overtemperature, reverse polarity protection, input surge protection |

| Dimensions | 220mm (W) x 160mm (H) x 250mm (D) |

| Weight | Approximately 5.8kg |

| Certification | IEC 61010-1, UL 508, CE, ATEX Zone 2, IEC 60950-1 |

| Redundancy | 1+1, N+1 redundant configuration support |

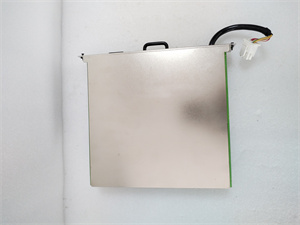

YOKOGAWA PW702

2. Product introduction

The YOKOGAWA PW702 is a high-power industrial switching power supply engineered to deliver robust 24V DC power to large-scale automation systems. Distinct from the low-voltage, lower-current PW482-11, it caters to high-power industrial equipment requiring stable and high-current power, making it a cornerstone in heavy-duty industrial environments.

With a total output current of 40A (20A per channel in dual output mode), this power supply can efficiently power multiple high-consumption devices such as large PLCs (like the CP461-50), motor drives, and heavy-duty actuators. Its support for 1+1 and N+1 redundant configurations ensures uninterrupted power supply to critical systems even in the event of multiple power supply unit failures. The PW702 operates reliably in extreme temperatures ranging from -25°C to 75°C, making it suitable for industries such as heavy manufacturing, oil and gas exploration, and large-scale mining operations. As a high-power industrial power solution, the YOKOGAWA PW702 guarantees the stable operation of large automation systems, reducing the risk of production interruptions caused by power issues.

3. Core advantages and technical highlights

High-power output with exceptional stability:

Unlike the 12V, 15A PW482-11, the PW702 provides 24V DC with 40A total current, ensuring sufficient power for high-energy-consuming equipment. In a steel mill’s rolling mill control system, it supplies power to large motor drives and hydraulic control systems, maintaining stable voltage even during sudden load changes (e.g., when the rolling force varies). The ±0.3% line regulation ensures that voltage fluctuations caused by grid instability do not affect the accuracy of the rolling process, which is crucial for ensuring the quality of steel products.

Wide input range and strong adaptability:

The PW702 accepts a wide input range of 85-264V AC and 120-370V DC, making it suitable for use in regions with unstable power grids or industrial sites with DC power sources. In remote mining areas where grid voltage often fluctuates, it can stably convert unstable AC power into reliable 24V DC power for underground mining equipment (connected via the ISC40G-TF-T1-05 switch), ensuring continuous operation of mining operations. This wide input range eliminates the need for additional voltage regulators, reducing system complexity and cost.

Advanced thermal management system:

Equipped with a high-efficiency heat sink and a dual-fan design with automatic speed control, the PW702 efficiently dissipates heat even at full load. In a high-temperature industrial environment such as a foundry, the fans adjust their speed according to the internal temperature of the power supply, ensuring that the unit operates within a safe temperature range without excessive noise. This thermal management system allows the PW702 to operate at 100% load in 75°C environments without derating, ensuring reliable power supply in harsh high-temperature conditions.

Flexible redundancy configurations:

Supporting 1+1 and N+1 redundant configurations, the PW702 provides a higher level of reliability than the PW482-11’s 1+1 redundancy. In a large-scale petrochemical plant’s distributed control system, multiple PW702 units form an N+1 redundant power supply system, ensuring that even if two units fail simultaneously, the remaining units can still supply power to critical equipment such as the NFPW444-50 security appliance and the CP461-50 PLC. This redundancy design minimizes the risk of system downtime caused by power supply failures, which is crucial for ensuring the safety of petrochemical production.

YOKOGAWA PW702

4. Typical application scenarios

In a large-scale water conservancy project’s pumping station, the PW702 powers multiple large water pumps’ control systems, including variable frequency drives and pressure sensors. Its high current output ensures that all pumps can start and operate simultaneously, while the stable voltage guarantees precise control of water flow. During periods of grid voltage fluctuations, the power supply maintains a stable output, preventing pump shutdowns that could lead to water supply interruptions. The redundant configuration ensures that even if one power supply unit fails, the pumping station can continue to operate normally.

In an automotive manufacturing plant’s welding workshop, the PW702 provides power to robotic welding arms and welding power sources. Its strong anti-interference ability prevents electromagnetic interference from welding equipment from affecting its output stability, ensuring that the robotic arms maintain precise positioning during welding. The high efficiency of the power supply (≥94%) reduces energy consumption, which is significant for reducing the overall energy cost of the workshop, which has a large number of welding robots.

In a data center’s industrial control area, the PW702 powers the cooling system’s control modules and security monitoring equipment. Its wide input range allows it to be powered by both the mains AC and the data center’s backup DC power system, ensuring uninterrupted operation of the cooling system during power outages. The power supply’s high reliability ensures that the temperature and humidity in the data center are always within the optimal range, protecting the safe operation of servers and network equipment.

5. Related model recommendations

- PW482-11: A low-voltage, low-current power supply suitable for small-scale low-power systems, ideal for use alongside the PW702in mixed-power environments where both high and low power devices are present.

- PW702-48: A 48V DC variant of the PW702with 20A total current, designed for systems requiring higher voltage and moderate current, such as certain communication equipment and industrial robots.

- CP461-50: The high-performance PLC optimally powered by the PW702, benefiting from its stable 24V output for reliable operation of complex control logic.

- RBPW-02: A high-power redundancy module compatible with the PW702, enabling 1+1 and N+1 redundant configurations to ensure uninterrupted power supply.

- ISC40G-TF-T1-05: The industrial Ethernet switch that pairs with the PW702, ensuring reliable network connectivity in high-power industrial automation systems.

- PW702-MON: A power supply monitoring module that works with the PW702, providing real-time monitoring of output voltage, current, and temperature, and sending alarms in case of abnormalities.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the PW702, ensure the mounting location has at least 300mm clearance for ventilation on all sides, with the ambient temperature within -25°C to 75°C. Prepare tools including a torque wrench (4.0-6.0Nm), wire strippers, and a high-precision multimeter.

For AC input, verify the voltage is 85-264V AC and install a 30A circuit breaker. For DC input, ensure the voltage is 120-370V DC and use a 20A breaker. Use 10mm² cables for output connections to handle 40A current, ensuring secure termination with cable lugs. In redundant configurations, connect multiple PW702 units to the RBPW-02 module, with separate input power sources for each unit to maximize reliability. Ground the unit using a 6mm² wire connected to the cabinet’s protective earth (PE) terminal.

Maintenance suggestions

Perform monthly visual inspections of the PW702 to check for loose connections, dust accumulation, or fan blockages. Clean the heat sink and fans with compressed air every two weeks in dusty environments to maintain heat dissipation efficiency. Monitor output voltage and current weekly using a precision multimeter to ensure they remain within the specified ranges (24V ±0.5% for voltage).

Check the status indicators daily: a green LED indicates normal operation, while red LEDs signal faults (e.g., overcurrent, overtemperature). Test the fan operation by manually increasing the load and confirming that the fans speed up accordingly. Calibrate the output voltage annually using the built-in adjustment potentiometer if necessary to maintain regulation accuracy.

If a fault occurs, first check the input power and load connections for abnormalities (e.g., short circuits in the CP461-50 PLC connections) before replacing the power supply. In redundant setups, use the RBPW-02 module to hot-swap the PW702 without interrupting power to the connected equipment, minimizing downtime.

7. Service and guarantee commitment

YOKOGAWA provides a 5-year warranty for the PW702, demonstrating confidence in its high-quality construction and reliable performance in high-power industrial applications. Each unit undergoes rigorous testing, including 2,000-hour temperature cycling (-25°C to 75°C), vibration testing (15g peak), and input surge testing (6kV), ensuring compliance with international industrial standards.

Our global technical support team includes specialists in high-power power supply systems, offering 24/7 assistance for installation, configuration, and troubleshooting. On-site support is available in major industrial regions with a response time of 24 hours for critical issues. YOKOGAWA provides detailed technical documentation and application notes specific to the PW702, helping customers integrate it effectively with high-power industrial equipment such as the CP461-50 PLC and large motor drives.

Comprehensive training programs are available, covering high-power power supply system design, redundancy configuration, and maintenance best practices for the PW702. Extended warranty options and preventive maintenance services are offered, including annual performance testing and thermal imaging inspections to identify potential issues before they cause failures, ensuring long-term reliable operation of critical high-power industrial systems.