Description

1. Detailed parameter table

| Parameter name | Parameter value |

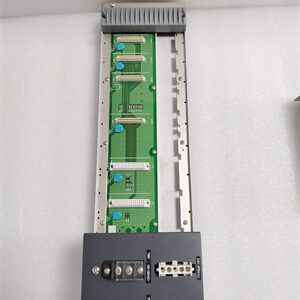

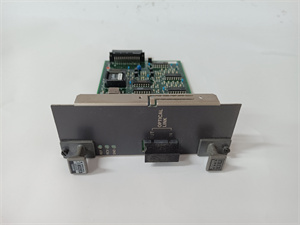

| Product model | SAI533-H33 |

| Manufacturer | YOKOGAWA |

| Product category | Industrial Analog Input Module |

| Number of Input Channels | 16 channels |

| Input Type | Voltage (0-10V DC), Current (4-20mA DC) |

| Resolution | 16-bit |

| Accuracy | ±0.05% of full scale (at 25°C ±5°C) |

| Sampling Rate | 100 samples/second per channel |

| Isolation | Channel-to-channel: 2.5kV AC (1min); Channel-to-backplane: 5kV AC (1min) |

| Operating Temperature Range | -10°C to 60°C |

| Power Consumption | ≤6W |

| Dimensions | 30mm (W) x 100mm (H) x 160mm (D) |

| Weight | Approximately 0.4kg |

| Certification | IEC 61131-2, UL 508, CE, ATEX Zone 2 |

YOKOGAWA SAI533-H33

2. Product introduction

The YOKOGAWA SAI533-H33 is a high-channel-density industrial analog input module designed for large-scale data acquisition in industrial automation systems. Distinct from the high-precision, bipolar SAI143-H63, this module focuses on providing a cost-effective solution for applications requiring multiple unipolar signal inputs, serving as a reliable interface between a large number of field sensors and control systems (such as the CP461-50 PLC).

Featuring 16 channels that support both voltage (0-10V DC) and current (4-20mA DC) inputs, the SAI533-H33 can connect to a wide array of sensors, including temperature transmitters, pressure transducers, and flow meters in large industrial facilities. With 16-bit resolution and ±0.05% accuracy, it ensures reliable measurement of process variables, which is essential for maintaining stable operations in large-scale systems. The module’s compact design and robust isolation make it suitable for industries such as water treatment, food and beverage production, and large manufacturing plants. As a key component in large data acquisition systems, the YOKOGAWA SAI533-H33 provides efficient and accurate data collection, enabling control systems to monitor and optimize complex industrial processes.

3. Core advantages and technical highlights

High channel density for large-scale systems:

With 16 channels (twice the number of the SAI143-H63), the SAI533-H33 is ideal for applications requiring simultaneous monitoring of multiple process variables. In a large water treatment plant, it can measure the pH level, turbidity, and chlorine concentration of water at 16 different points in the treatment process, all through a single module. This reduces the number of modules needed in the control cabinet, saving space and lowering system costs while simplifying wiring and maintenance.

Cost-effective multi-sensor integration:

The SAI533-H33 offers a balance of performance and cost, making it suitable for large-scale applications where the high precision of the SAI143-H63 is not required. In a food and beverage production line with multiple production lines, it can monitor the temperature and pressure of each line’s equipment, providing sufficient accuracy for process control at a lower cost per channel compared to the SAI143-H63. This cost-effectiveness allows for comprehensive monitoring of all production lines without exceeding budget constraints.

Flexible mixed-signal input:

The module’s ability to accept both voltage (0-10V) and current (4-20mA) signals on the same module, with each channel configurable individually, provides great flexibility in system design. In a large manufacturing plant, it can connect to 4-20mA pressure sensors on one set of channels and 0-10V level sensors on another set, all within the same module. This eliminates the need for separate modules for different sensor types, simplifying system integration and reducing the number of modules in the control cabinet.

Compact design for space-constrained cabinets:

Measuring just 30mm in width, the SAI533-H33 offers 16 channels in a slim form factor, maximizing space utilization in control cabinets. In a space-constrained control room of a large power plant, it fits alongside the ISC40G-TF-T1-05 switch and PW702 power supply, providing ample input channels without increasing the size of the cabinet. This compact design is particularly valuable in retrofitting existing systems where space is limited.

YOKOGAWA SAI533-H33

4. Typical application scenarios

In a large-scale food processing plant with multiple production lines, the SAI533-H33 monitors the temperature, pressure, and flow rate of ingredients in each line. Each of the 16 channels is connected to a different sensor, providing real-time data to the CP461-50 PLC. The PLC uses this data to adjust the operation of each line’s equipment (via the S2BN5D-121 DO module), ensuring consistent product quality across all lines. The module’s cost-effectiveness allows for comprehensive monitoring of all lines without a significant increase in system cost.

In a municipal water treatment plant, the SAI533-H33 is used to monitor various parameters at different stages of the treatment process, including raw water intake, filtration, and disinfection. It measures the pH level, turbidity, and chlorine concentration at 16 different points, providing the control system with a comprehensive view of the treatment process. This enables operators to detect and address issues promptly, ensuring the quality of the treated water meets regulatory standards.

In a large manufacturing plant with multiple machines, the SAI533-H33 collects data from sensors monitoring the temperature, vibration, and pressure of each machine. This data is used by the PLC to track the performance of each machine and predict potential failures, allowing for preventive maintenance. The module’s 16 channels ensure that all critical parameters of each machine are monitored, reducing the risk of unexpected downtime and improving overall production efficiency.

5. Related model recommendations

- SAO533-H33: The analog output counterpart to the SAI533-H33, providing control signals to actuators based on the data collected by the input module.

- SAI143-H63: The high-precision, bipolar analog input module for applications requiring higher accuracy and bipolar signal measurement, which can be used alongside the SAI533-H33in systems with mixed precision requirements.

- CP461-50: The high-performance PLC that processes the data from the SAI533-H33, leveraging its processing power to handle the large volume of data from 16 channels.

- PW482-10 S2: The dual-input power supply that provides stable power to the SAI533-H33, ensuring reliable operation even in fluctuating power conditions.

- S2BN5D-121 DO: The digital output module that acts on the control decisions derived from the SAI533-H33‘s data, adjusting the operation of field equipment.

- F3PU50-0N: The HMI panel that displays real-time data from the SAI533-H33, allowing operators to monitor multiple process variables simultaneously.

6. Installation, commissioning and maintenance instructions

Installation preparation

Before installing the SAI533-H33, ensure the mounting rail is securely fastened in a control cabinet with ambient temperature between -10°C and 60°C. Prepare tools including a torque screwdriver (0.5-1.5Nm), wire strippers, and a multimeter.

Verify that the backplane power (typically 5V DC from the PLC rack) is within specifications. Use shielded twisted-pair cables for all sensor connections, with the shield grounded at the sensor end to minimize noise interference. For current inputs, ensure proper wiring (including loop power if required by the sensor), and for voltage inputs, use short cable runs to prevent signal degradation. Label each of the 16 channels clearly to match the connected sensor, simplifying troubleshooting.

Maintenance suggestions

Perform quarterly visual inspections of the SAI533-H33 to check for loose connections, dust accumulation, or signs of corrosion. Clean the module’s surface with a dry, lint-free cloth if necessary, taking care not to disturb the wiring. Calibrate the module annually using a precision signal generator to maintain its ±0.05% accuracy, ensuring reliable measurement of process variables.

Monitor the module’s status indicators: a steady green LED indicates normal operation, while red or flashing LEDs signal faults (e.g., overvoltage, communication errors). Use the PLC’s diagnostic software to check for drift in individual channels, which may indicate a need for recalibration or sensor replacement. If a channel fails, first test the connected sensor and wiring before replacing the module.

Store spare modules in a dry, static-free environment, preferably in anti-static packaging. Document the wiring configuration and channel assignments to facilitate quick replacement and troubleshooting.

7. Service and guarantee commitment

YOKOGAWA provides a 5-year warranty for the SAI533-H33, reflecting confidence in its reliability as a high-channel-density analog input module. Each module undergoes rigorous testing, including temperature cycling, vibration testing, and isolation resistance verification, ensuring compliance with industrial standards.

Our technical support team offers 24/7 assistance for installation, configuration, and troubleshooting, with specialists experienced in large-scale data acquisition systems. On-site support is available in major industrial regions with a 48-hour response time for non-critical issues. YOKOGAWA provides detailed wiring diagrams and integration guides specific to the SAI533-H33, helping customers connect it seamlessly with a large number of sensors and control systems.

Training programs cover analog input module maintenance and large-scale data acquisition system design, ensuring customers maximize the performance of the SAI533-H33 in their specific applications. Extended warranty options and preventive maintenance services are available, including periodic function testing to identify potential issues before they cause failures, ensuring long-term reliable operation in large-scale industrial systems.