Description

Detailed Parameter Table

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

UP55A-001-11-00

|

|

Manufacturer

|

YOKOGAWA

|

|

Product Category

|

Digital Controller

|

|

Power Supply

|

100 – 240V AC

|

|

Program Modes

|

30 types

|

|

Program Segments

|

Up to 99 segments per mode, 300 total segments

|

|

Event Monitoring

|

8 PV events, 16 time events, and 8 alarms simultaneously

|

|

Control Functions

|

5 built-in control functions and algorithms, supporting standard control

|

|

Communication Functions

|

RS-485 as standard (up to 38.4kbps, 2-wire/4-wire); optional Ethernet, CC-Link, PROFIBUS-DP, DeviceNet

|

|

Display

|

14-segment large color LCD, English display

|

|

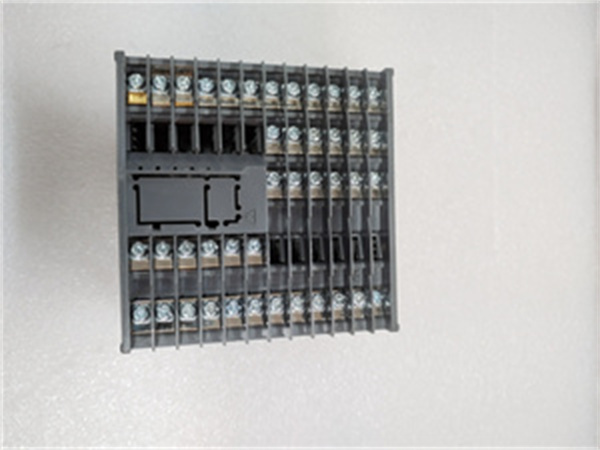

Port Configuration

|

8 DI ports, 8 DO ports; expandable with remote inputs, auxiliary analog inputs, additional DO ports

|

|

Dimensions

|

Approximately 76H x 29.5W x 124.5D (mm)

|

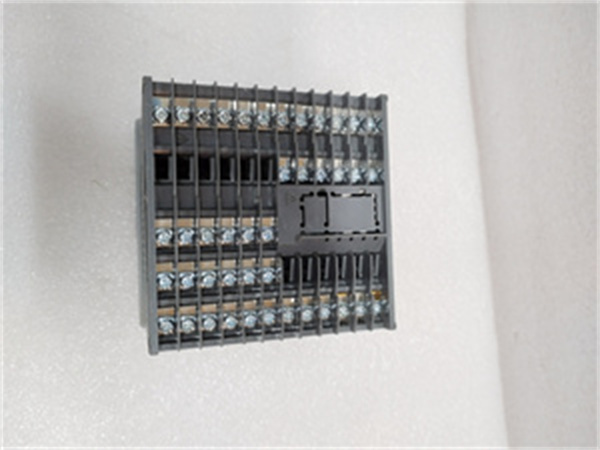

YOKOGAWA UP55A-001-11-00

Product Introduction

YOKOGAWA UP55A-001-11-00 is a sophisticated digital controller meticulously engineered by YOKOGAWA, playing a pivotal role in industrial automation processes. As a core control unit within YOKOGAWA’s industrial automation product line, it delivers precise control for various complex industrial processes through advanced technology.

This controller features extensive program modes to meet diverse control requirements. Its robust event monitoring capability tracks multiple process variable events, time events, and alarms simultaneously, ensuring system operational safety and stability. Within automation systems, UP55A-001-11-00 connects various sensors and actuators, providing accurate parameter regulation based on set parameters to ensure efficient, stable operation of entire production processes.

Core Advantages and Technical Highlights

- Precise Control: YOKOGAWA UP55A-001-11-00 utilizes advanced algorithms and built-in control functions to respond rapidly to process variable changes, achieving high-precision parameter adjustment. This ensures stable industrial production processes and consistent product quality, such as precisely controlling temperature and pressure in chemical reactions.

- Rich Program Configuration: With up to 30 program modes, each supporting 99 segments (300 total segments), this controller easily handles complex control requirements across different industrial scenarios. Whether for continuous production or batch operations, it offers flexible programming capabilities.

- Flexible Communication Expansion: Supporting multiple communication protocols including standard RS-485 and optional Ethernet, CC-Link, etc., UP55A-001-11-00 seamlessly integrates into various automation systems. This enables efficient data exchange with other equipment and facilitates remote monitoring and control, significantly enhancing industrial production intelligence.

Typical Application Scenarios

In the chemical industry, YOKOGAWA UP55A-001-11-00 controls temperature and pressure in chemical reactors. Its precise regulation ensures chemical reactions proceed under optimal conditions, improving product yield and quality while reducing energy consumption.

Within petroleum refining, it provides accurate control for distillation columns and related equipment, ensuring effective separation of different boiling point fractions to enhance production efficiency and product quality. In power generation, UP55A-001-11-00 monitors and controls generator operating parameters, ensuring stable power supply, detecting potential faults early, and improving power system reliability.

YOKOGAWA UP55A-001-11-00

Related Model Recommendations

- UP55A-000-11-00: Same series as UP55A-001-11-00 with similar basic functions but featuring standard control type, ideal for applications with basic control requirements.

- UP55A-002-11-00: Specialized for heating/cooling control applications requiring precise temperature regulation, such as heat treatment processes.

- UT55A-020-11-00: Temperature-focused controller that complements UP55A-001-11-00 for comprehensive temperature-related control solutions.

- UP550-00: YOKOGAWA temperature controller serving as a simplified alternative to UP55A-001-11-00 in small-scale industrial control scenarios.

- UP55A-012-11-00: Features RS-485 communication at up to 19.2kbps, providing an economical option to UP55A-001-11-00 for cost-sensitive projects with lower communication speed requirements.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing YOKOGAWA UP55A-001-11-00, ensure the environment temperature remains within specified ranges, avoiding high temperatures, humidity, or strong electromagnetic interference. Prepare appropriate tools including screwdrivers and wrenches. Inspect equipment for physical damage and check all interfaces for integrity. Follow wiring diagrams precisely to ensure correct power connections and prevent short circuits. Pay attention to module orientation during installation and ensure secure mounting.

Maintenance suggestions: Regularly clean UP55A-001-11-00 to prevent dust accumulation that could affect heat dissipation and electrical performance. Daily inspections should monitor operating status, checking display parameters and alarm indicators. For troubleshooting, refer to the manual to identify fault types—check power and wiring for output signal issues, or inspect sensors if regulation accuracy declines. Always use genuine YOKOGAWA replacement parts to maintain equipment performance.

Service and Guarantee Commitment

YOKOGAWA provides reliable quality assurance for UP55A-001-11-00, with a specified warranty period under normal operating conditions. Our professional after-sales team responds promptly to quality issues, offering technical support and solutions. Whether addressing installation questions or troubleshooting operational problems, customers receive timely, effective assistance. Backed by extensive industry experience and technical expertise, YOKOGAWA ensures users can confidently rely on UP55A-001-11-00 for robust industrial automation performance.