Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | YS1700-100/A06/A31 |

| Manufacturer | YOKOGAWA |

| Product Category | Programmable Indicator Controller |

| Display | Full dot matrix color LCD |

| Programming Capacity | 1000 steps for text program, 400 functional modules for function block program |

| Control Algorithms | Multiple, such as PID |

| Calculation Function | IEEE754 format 4-byte floating-point calculation, over 100 calculation modules |

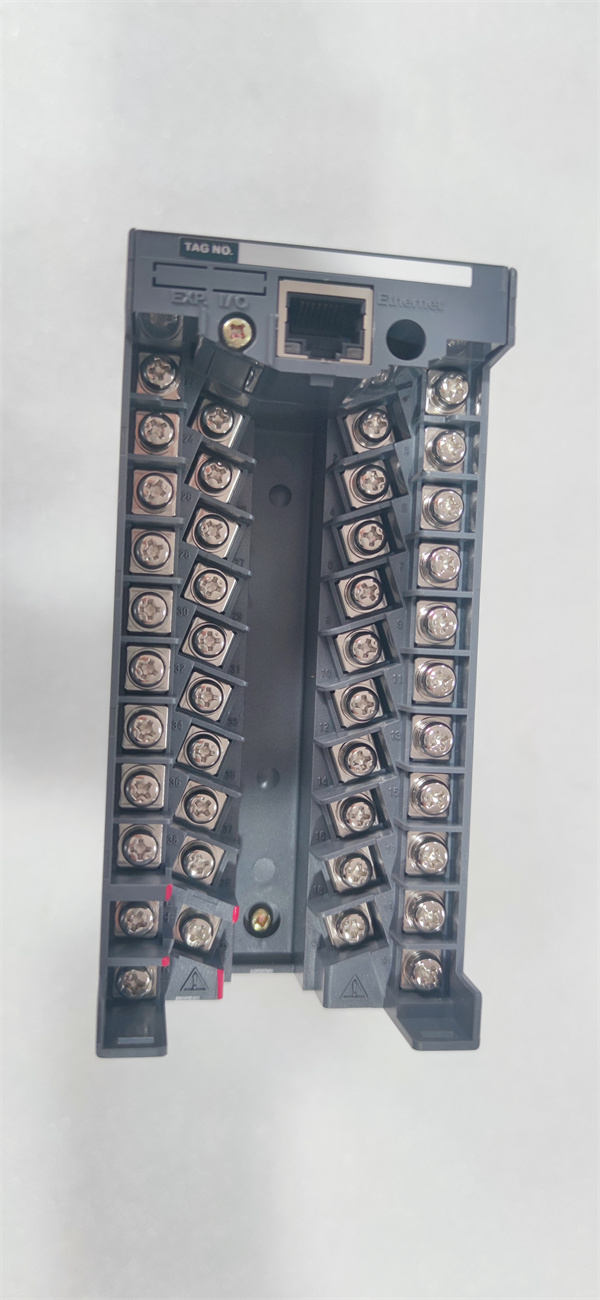

| I/O Configuration (Expandable I/O Type) | 8 analog inputs, 4 analog outputs, 14 digital inputs and outputs (10 digital inputs or 10 digital outputs) |

| Power Supply | AC(100V) or DC(24V), DC power supply can receive non-polarized power (220V AC power needs to be specified when ordering) |

| Dimensions | Smaller and more compact compared to previous series, specific dimensions refer to product manual |

| Protection Level | Dustproof/drip-proof IP54 panel (basic model only) |

| Certifications | CE mark (basic model and YS100 compatible model only), FM non-flammable explosion-proof protection (optional for basic model) |

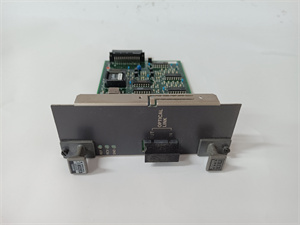

| Communication Interfaces (Optional) | Ethernet (Modbus/TCP; basic model only), RS485 (PC Link, Modbus, point-to-point communication and YS protocol; not applicable to YS80 internal unit compatible model), DCS – LCS communication |

YOKOGAWA YS1700-100/A06/A31

Product Introduction

YOKOGAWA YS1700-100/A06/A31 is a programmable indicator controller specifically designed for industrial automation and process control scenarios. It belongs to YOKOGAWA’s advanced YS1000 series products. Leveraging outstanding technology, it can precisely adapt to various complex industrial demands. By running user programs, YS1700-100/A06/A31 can achieve customized functions. Whether it is temperature and pressure control in chemical production or equipment operation monitoring in manufacturing, it can play a crucial role.

This controller features excellent display performance. The full dot matrix color LCD ensures clear visibility even under direct sunlight, facilitating operators to obtain key information at any time. Its powerful programming and computing capabilities, combined with rich control and calculation functions, provide a stable and efficient control core for industrial automation processes, greatly enhancing the accuracy and reliability of the production process.

Core Advantages and Technical Highlights

- Advanced Programming Modes: In addition to text programming compatible with earlier models, YS1700-100/A06/A31introduces a new GUI-based function block programming method. With the YSS1000 setting software, users can develop programs more conveniently. The capacity of 400 functional modules for function block programs and 1000 steps for text programs can meet complex programming requirements.

- Powerful Computing and Control: It adopts IEEE754 format 4-byte floating-point calculation, which can accurately use actual values for operations. With over 100 calculation modules covering exponential and logarithmic functions, as well as temperature and pressure compensation, it can flexibly handle various industrial computing scenarios and achieve precise control.

- Flexible Function Selection: In the multi-functional controller mode, the control method can be selected from commonly used functions (such as single-loop, cascade, or selector control) without programming. Through parameter setting, the function allocation of digital and analog inputs/outputs can be easily determined, improving operational convenience and flexibility.

- High Reliability Design: The dual-CPU structure (one for control and one for display) ensures that even if one CPU fails, display and manual operation can still be maintained. The hard manual circuit independent of the digital circuit can still manually adjust the controller output when the digital circuit fails. Non-volatile memory is used for memory backup, eliminating the need for batteries or capacitors, reducing maintenance costs, and enhancing system stability and reliability.

Typical Application Scenarios

In the chemical industry, YOKOGAWA YS1700-100/A06/A31 can be used for precise control of key parameters such as temperature and pressure in chemical reaction processes. Utilizing its powerful computing and control functions, it ensures that chemical reactions proceed under optimal conditions, improving product quality and production efficiency while guaranteeing the safety and stability of the production process.

In food and beverage production, this controller can monitor and control the operating status of various equipment on the production line in real-time. For example, by controlling the speed of conveyor belts and the start/stop of equipment, it realizes the efficient connection of the production process, ensures the consistency of product quality, and simultaneously improves the overall automation level of the production line.

In the energy and power field, YS1700-100/A06/A31 can monitor and adjust the operating parameters of power generation equipment. Through precise control algorithms, it maintains the stable operation of equipment, discovers and handles potential faults in a timely manner, and guarantees the reliability and stability of power supply.

YOKOGAWA YS1700-100/A06/A31

Related Model Recommendations

- YS1700-100/A06/A30: Belongs to the same YS1700 series as YS1700-100/A06/A31, with similar basic functions but differences in some configuration details, suitable for industrial scenarios with slightly different functional requirements.

- YS1500: Another product in the YS1000 series with relatively basic functions. It can be used as an alternative to YS1700-100/A06/A31in scenarios with limited budgets or less complex control requirements.

- YS1360: Mainly used as a manual station for MV setting, often used in conjunction with YS1700-100/A06/A31, playing an important role in some industrial processes that require manual intervention.

- YS100 Series: YS1700-100/A06/A31upgrades the functions and performance of the YS100 series. The YS100 series is suitable for the transformation of some old systems with relatively low requirements for controller performance and limited budgets.

- YS1700-200/A06/A31: Some functions are enhanced or expanded on the basis of YS1700-100/A06/A31, which can meet complex industrial application scenarios with higher requirements for controller performance.

Installation, Commissioning and Maintenance Instructions

- Installation Preparation: Before installing YOKOGAWA YS1700-100/A06/A31, ensure that the installation environment meets the requirements. The temperature should be within the appropriate range, and avoid humid, dusty, or strongly electromagnetically interfered environments. Prepare common installation tools such as screwdrivers and wrenches. Carefully check the appearance of the product for any damage and ensure the integrity of all interfaces. Wire strictly in accordance with the installation manual to ensure correct power connection. Pay attention to distinguishing between AC and DC power wiring methods and properly ground to ensure the safe operation of the equipment. When installing, pay attention to the installation direction and fixing method of the controller to ensure stable installation.

- Maintenance Suggestions: Regularly clean YS1700-100/A06/A31to prevent dust accumulation from affecting heat dissipation and performance. During daily operation, closely monitor the parameters on the display screen and check for any abnormal alarm information. If a failure occurs, troubleshoot according to the fault code prompt in combination with the product manual. For example, if the control output is abnormal, check whether the wiring is loose or the control program is incorrect; if the display is abnormal, consider whether the display screen or the relevant circuit is faulty. When replacing spare parts, be sure to use original YOKOGAWA accessories to ensure stable equipment performance and operation safety.

Service and Guarantee Commitment

YOKOGAWA provides comprehensive services and guarantees for YS1700-100/A06/A31. The product comes with a certain quality assurance period. During the warranty period, if the product fails due to quality problems, YOKOGAWA will provide free maintenance or replacement services. The company has a professional after-sales technical team that can provide technical support to customers at any time. Whether it is questions during installation and commissioning or troubleshooting during use, it can respond quickly and provide effective solutions. With rich industry experience and advanced technical strength, YOKOGAWA is committed to providing customers with reliable products and high-quality services, allowing customers to use YS1700-100/A06/A31 with confidence and escorting industrial automation production.