Description

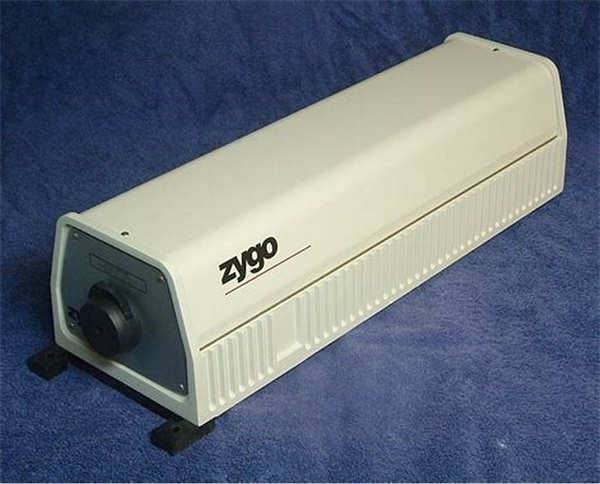

ZYGO 7702: Product Overview

The ZYGO 7702 is a dual-frequency helium-neon laser head from ZYGO’s ZMI™ series, designed for use in precision metrology systems. As a critical component of interferometric setups, it emits a stabilized, two-frequency laser beam that serves as the foundation for ultra-precise displacement and position measurements.

Role in Metrology Systems:

Positioned as the “light source” in ZYGO’s interferometric systems, the 7702 performs two primary functions:

-

Frequency Stabilization: Delivers a two-frequency laser output with minimal frequency drift, ensuring the accuracy of displacement calculations in interferometers.

-

Beam Quality Maintenance: Provides a collimated, polarized laser beam with low noise, critical for maintaining the integrity of interference patterns.

Core Functionality:

-

Dual-Frequency Output: Emits two orthogonally polarized frequencies (e.g., f1 and f2) to enable heterodyne interferometry, a technique that achieves sub-nanometer resolution by measuring frequency differences between the reference and measurement beams.

-

Compact Design: Features a rugged, compact enclosure (6 mm beam diameter) suitable for integration into space-constrained metrology systems.

-

Compatibility: Works seamlessly with ZYGO’s ZMI™ 240X and 4X04 series measurement boards, as well as third-party interferometer systems that support dual-frequency laser inputs.

Platform Benefits (ZMI™ Series):

The 7702 leverages ZYGO’s expertise in nanoscale metrology, offering:

-

Reliability: Industrial-grade components and a robust design ensure 24/7 operation in cleanroom environments (e.g., semiconductor fabs).

-

Scalability: Can be combined with multiple laser heads to enable multi-axis displacement measurements, making it suitable for applications like wafer stage positioning in semiconductor manufacturing.

-

Ease of Integration: Compatible with existing ZYGO measurement systems, reducing setup time and effort for engineers.

ZYGO 7702

Technical Specifications

-

Model Number: 7702 (ZMI 7702)

-

Manufacturer: ZYGO (AMETEK)

-

Product Type: Dual-Frequency Helium-Neon Laser Head

-

Laser Medium: Helium-Neon (HeNe)

-

Wavelength: 632.8 nm (±0.1 nm)

-

Output Power: >650 μW (typical)

-

Beam Diameter: 6 mm (nominal)

-

Polarization: Collinear, orthogonally linear polarized

-

Operating Temperature: 20°C ± 0.1°C (water-cooled for enhanced stability)

-

Weight: 12 kg (26.5 lbs)

-

Certifications: CE, UL (inferred from ZYGO industrial product standards)

Core Features & Customer Value

1. High Stability for Precision Measurements:

The 7702’s dual-frequency output and frequency stabilization circuitry ensure minimal frequency drift, which is critical for maintaining the accuracy of interferometric measurements. For customers in semiconductor manufacturing, this means consistent wafer positioning accuracy (sub-nanometer level) during lithography, reducing defects and improving yield.

2. Compatibility with ZMI™ Ecosystem:

The 7702 is designed to work seamlessly with ZYGO’s ZMI™ 240X and 4X04 series measurement boards, enabling customers to leverage their existing ZYGO equipment for nanoscale measurements. This compatibility reduces integration time and costs, making it easier for customers to upgrade their metrology systems.

3. Rugged Industrial Design:

The laser head’s rugged enclosure and water-cooling system make it suitable for operation in cleanroom environments, where temperature and humidity are tightly controlled. Customers can rely on the 7702 to maintain performance even in demanding conditions, minimizing downtime and maintenance costs.

4. Cost-Effective Solution:

Compared to other high-stability laser sources, the 7702 offers a cost-effective solution for customers who need dual-frequency laser output for interferometric measurements. Its compatibility with ZYGO’s measurement boards also reduces the need for additional hardware, further lowering costs.

ZYGO 7702

Typical Applications

The ZYGO 7702 is widely used in industries requiring ultra-precise displacement measurement:

-

Semiconductor Manufacturing:

-

Wafer Stage Positioning: Provides the laser source for interferometric systems that position wafers with nanometer-scale accuracy during lithography. For example, in a 7nm semiconductor fab, the 7702 enables the positioning of wafers to within 0.1 nm of the target position, ensuring that the lithographic pattern is printed correctly.

-

Mask Alignment: Used in mask alignment systems to ensure that the photomask is positioned accurately relative to the wafer, preventing defects in the printed circuit.

-

-

Optical Manufacturing:

-

Lens Testing: Enables the measurement of lens surface figure and wavefront aberrations with sub-nanometer resolution. For example, in the production of high-power laser lenses, the 7702 is used to verify that the lens surface is free of defects that could degrade laser performance.

-

Optical Component Metrology: Used to measure the thickness and refractive index of optical components (e.g., glass wafers, prisms) with high precision.

-

-

Nanotechnology:

-

Atomic Force Microscopy (AFM): Provides the laser source for AFM systems that image surfaces at the atomic scale. The 7702’s high stability ensures that the AFM’s cantilever deflection measurements are accurate, enabling researchers to study nanomaterials with unprecedented detail.

-

Nanopositioning: Used in nanopositioning systems to control the movement of stages with nanometer-scale resolution, enabling applications like single-molecule manipulation and nanoassembly.

-