Description

1. Product Description

2. Product Parameters

| Parameter | Details |

|---|---|

| Voltage Supply | 24 V DC (±10%) |

| Power Consumption | ≤15 W |

| Communication Interfaces | Ethernet (10/100 Mbps), PROFIBUS DP, Modbus RTU |

| Processor | 32-bit RISC CPU |

| Memory | 512 MB RAM, 1 GB Flash |

| Input/Output Channels | Supports up to 128 I/O points (expandable via extension modules) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 200 mm × 150 mm × 80 mm |

| Weight | 1.2 kg |

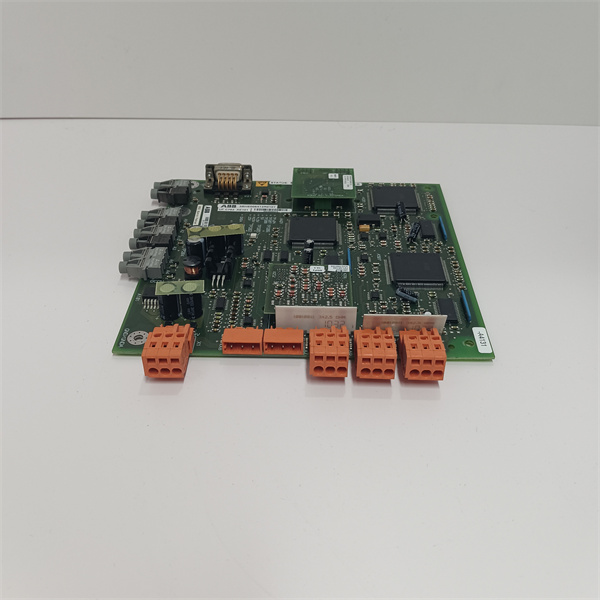

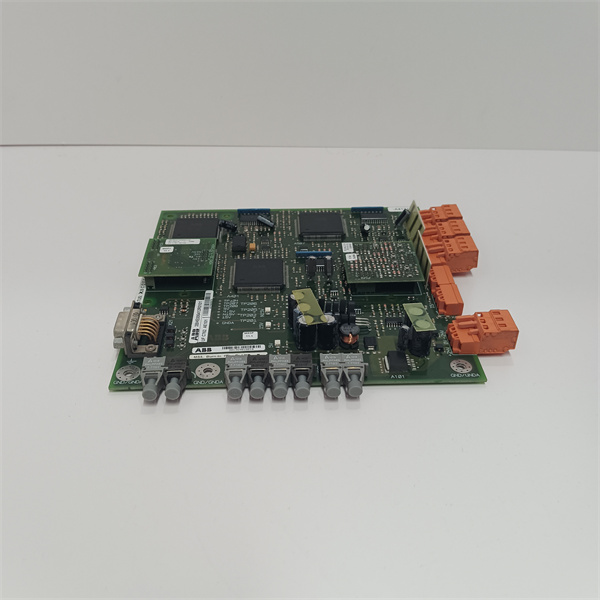

3BHE006412R0101 UFC762AE101

3. Advantages and Features

4. Application Areas and Use Cases

5. Competitor Comparison

Compared to similar control modules, ABB 3BHE006412R0101 UFC762AE101 stands out for its seamless integration with ABB’s ecosystem, including drives, motors, and HMI solutions, reducing engineering effort by up to 40%. Its advanced cybersecurity features, such as secure firmware updates and encrypted communication protocols, exceed industry standards for protection against cyber threats. The module’s long lifecycle support (10+ years) and global service network also provide a competitive advantage for customers requiring long-term system stability.

3BHE006412R0101 UFC762AE101

6. Selection Recommendations

- System Compatibility: Ensure it aligns with your existing ABB control system (e.g., AC 800M, PLC platforms).

- I/O Expansion Needs: Evaluate whether the base module’s I/O capacity and expandability meet your application’s current and future requirements.

- Environmental Demands: Confirm the module’s specifications (e.g., temperature range, vibration resistance) match your installation environment.

- Software Requirements: Verify compatibility with your preferred programming languages (e.g., CODESYS, CFC, Ladder Logic).

7. Precautions

- Installation: Follow ABB’s official guidelines to ensure proper grounding and wiring, avoiding signal interference and electrical hazards.

- ESD Protection: Use anti-static equipment during handling to prevent damage to sensitive electronic components.

- Firmware Management: Regularly update firmware through ABB’s approved channels to address security patches and performance optimizations.

- Redundancy Testing: For critical applications, test redundancy functions periodically to ensure failover mechanisms operate correctly.

- Environmental Monitoring: Avoid exposing the module to direct moisture, dust, or corrosive gases, and use appropriate enclosures if necessary.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.