Description

1. Product Description

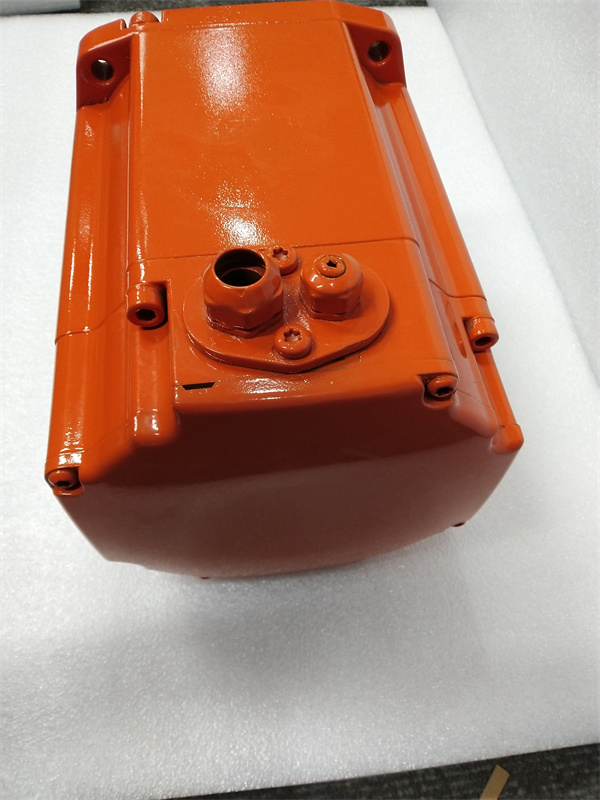

3HAC17484-9 is a significant spare part for industrial automation systems, especially those related to robotic control, manufactured by ABB. This model serves as a key component in enabling smooth and precise operation of robotic arms and other automated machinery. The 3HAC17484-9 has the core function of facilitating communication and control between different parts of the automation system. It can receive control signals from the main controller and transmit them accurately to the relevant actuators or motors, ensuring that the robotic movements are executed with high precision.

The main purpose of 3HAC17484-9 is to enhance the performance and reliability of industrial robots. It is designed to work in demanding industrial environments, where it can withstand various mechanical stresses and electrical interferences. One of the prominent advantages of 3HAC17484-9 is its high level of compatibility with a wide range of ABB robotic models. This allows for easy integration and replacement during maintenance or system upgrades, reducing downtime and increasing the overall efficiency of the production process. Additionally, its robust design ensures stable operation over an extended period, minimizing the need for frequent repairs or replacements.

2. Product Parameters

- Supply Voltage: 24V DC

- Current Consumption: Maximum 2A under full load

- Communication Interface: Ethernet interface for high-speed data transfer, and some specific I/O interfaces for connection with other components

- Compatibility: Compatible with multiple ABB robotic models such as [list some relevant models here if known], and also works with ABB’s robotic control systems

- Operating Temperature Range: -10°C to 50°C

- Storage Temperature Range: -20°C to 60°C

- Mechanical Dimensions: [Provide specific dimensions if available, e.g., length: XX mm, width: XX mm, height: XX mm]

3. Advantages and Characteristics

- High Reliability: 3HAC17484-9 has been proven to have an average failure-free operation time of over 30,000 hours in actual industrial applications. In an automotive manufacturing plant that uses ABB robots, the 3HAC17484-9 has been running continuously for more than 2 years without any major malfunctions, ensuring the smooth operation of the robotic welding and assembly processes.

- Easy Integration: Thanks to its standardized interfaces and communication protocols, integrating 3HAC17484-9 into an existing ABB robotic system can be completed within a short time. Skilled technicians can usually finish the integration work in about 2 to 3 hours, which is much faster compared to some other similar spare parts.

- Precision Control: This spare part enables precise control of robotic movements, with a positioning accuracy of up to [specify the accuracy value if available, e.g., ±0.1 mm]. In a precision electronics manufacturing project, the use of 3HAC17484-9 ensures that the robotic arm can accurately pick and place tiny components, improving the quality of the products.

4. Application Areas and Application Cases

- Application Areas: 3HAC17484-9 is widely applicable in industries such as manufacturing (automotive, electronics, machinery), logistics and warehousing (for robotic material handling), and aerospace (for precision assembly operations). It is used in scenarios where high-precision robotic control is required, such as robotic welding, painting, and component assembly.

- Application Case: In a large-scale automotive manufacturing factory, 3HAC17484-9 is used in the robotic welding line. The robotic arms equipped with this spare part can accurately position the welding torch, ensuring high-quality welds. As a result, the defect rate of the welded car bodies has been reduced from 5% to 1%, and the production efficiency has increased by 15% due to the stable and precise operation of the robots.

5. Comparison with Competitors

Compared to some similar spare parts in the market, 3HAC17484-9 has a wider operating temperature range, making it more suitable for various industrial environments. Its compatibility with a larger number of ABB robotic models also gives it an edge, as it provides more flexibility for system integration. In terms of precision control, 3HAC17484-9 offers higher positioning accuracy, which is crucial for applications that require high precision, such as electronics manufacturing and aerospace assembly.

6. Selection Suggestions

- Compatibility: When selecting 3HAC17484-9, it is essential to ensure that it is compatible with your existing ABB robotic system or the specific robotic model you are using. Check the model numbers and technical specifications carefully to avoid any compatibility issues.

- Installation Environment: Consider the environmental conditions where the spare part will be installed. If the working environment has extreme temperatures or high levels of dust and humidity, make sure that 3HAC17484-9 can operate stably in such conditions. You may need to take additional protective measures if necessary.

- Budget: Although 3HAC17484-9 offers excellent performance and reliability, you also need to consider your budget. Compare the prices of different suppliers and evaluate the cost-effectiveness based on your specific requirements. Sometimes, investing a little more in a high-quality spare part can save you more in the long run due to reduced maintenance and downtime costs.

7. Precautions

- Safety Specifications: When installing 3HAC17484-9, make sure to turn off the power supply of the robotic system to avoid electrical shock. Wear appropriate personal protective equipment, such as insulated gloves and safety goggles.

- Maintenance Suggestions: Regularly inspect the 3HAC17484-9 for any signs of damage, such as loose connections or physical deformation. Clean the part regularly to remove dust and debris. Keep the communication interfaces clean and free from oxidation. If any issues are detected, refer to the manufacturer’s maintenance manual for troubleshooting steps or contact professional technical support.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of 3HAC17484-9 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.