Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage Rating | 4500 V RMS |

| Continuous Current | 1000 A (I<sub>T(AV)</sub>) |

| Peak Repetitive Off-State Voltage | 6000 V |

| Di/dt Rating | 150 A/μs |

| dv/dt Rating | 1000 V/μs |

| Case Temperature | -40°C to +125°C |

| Mounting Style | Press-fit or bolt-down |

| Package Type | Hermetically sealed ceramic |

| Turn-On Time | ≤ 5 μs |

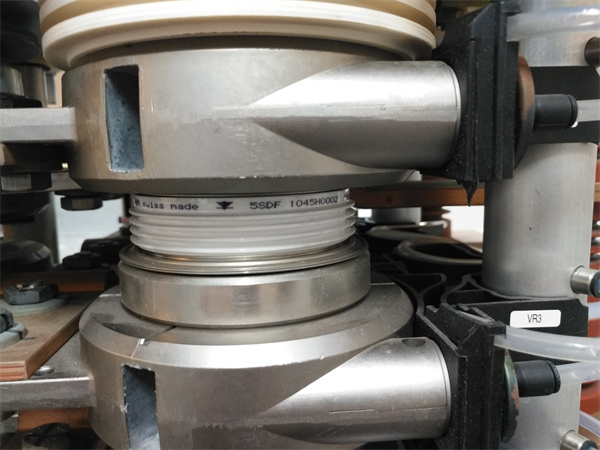

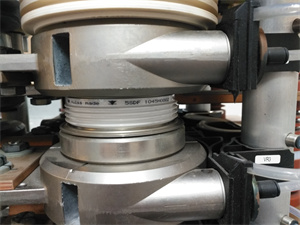

5SDF1045H0002

3. Advantages and Features

4. Application Areas and Case Studies

5. Competitive Comparison

Compared to comparable thyristor modules, ABB 5SDF1045H0002 offers higher current handling capacity and improved thermal management, with a thermal resistance (Rth) of 0.015 K/W, enabling better heat dissipation in compact designs. Its advanced gate drive technology reduces triggering energy requirements by 30%, enhancing compatibility with modern control systems. The module’s compliance with international standards (IEC 60747-6) ensures global usability, while its rugged construction minimizes failure rates in high-vibration environments.

5SDF1045H0002

6. Selection Recommendations

- Power Requirements: Ensure the voltage and current ratings match your system’s peak and continuous load demands.

- Cooling System: Pair the module with an adequate heat sink or cooling solution to maintain case temperature within specified limits.

- System Integration: Verify compatibility with your existing gate drive circuitry and control protocols.

- Environmental Demands: Assess exposure to moisture, dust, or vibrations to confirm the module’s sealed package suits your application.

7. Precautions

- Electrical Handling: Avoid static discharge during installation; use anti-static wrist straps and grounding procedures.

- Thermal Management: Ensure proper thermal interface material (e.g., thermal grease) is applied between the module and heat sink to optimize heat transfer.

- Overvoltage Protection: Install surge arresters or snubber circuits to protect against voltage spikes during switching operations.

- Maintenance Checks: Regularly inspect for physical damage or signs of thermal stress, such as discoloration on the module’s housing.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.