Description

1. Product Description

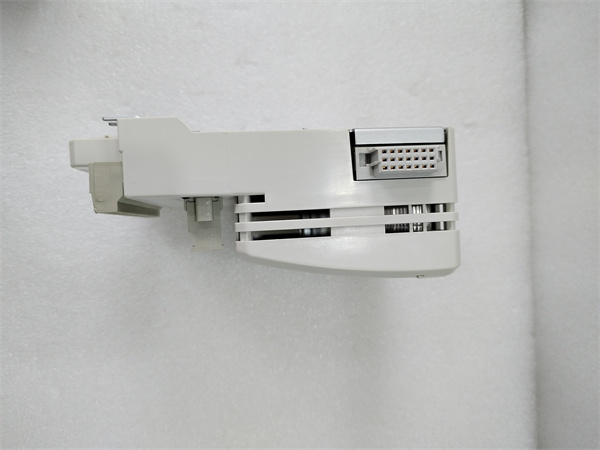

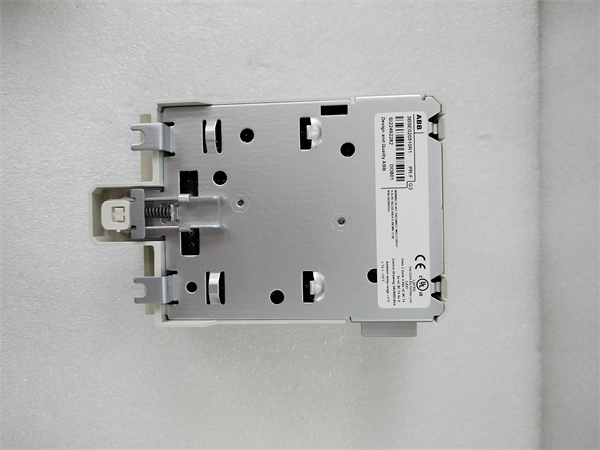

ABB DO801 is a high-performance digital output module designed for industrial automation systems, offering reliable control of discrete devices such as relays, motors, and indicators. As a key component of ABB’s PLC and distributed control system (DCS) portfolio, DO801 enables precise switching of 8 independent output channels, each capable of handling 24 V DC signals. This module is engineered to deliver robust performance in harsh industrial environments, featuring advanced diagnostics, surge protection, and compatibility with ABB’s AC500 and PLCnext controller platforms. ABB DO801 simplifies system integration, enhances operational efficiency, and ensures seamless communication between the controller and field devices, making it an ideal choice for automation applications requiring high reliability and scalability.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Channels | 8 isolated digital outputs |

| Output Type | Transistor (sink/source, depending on model) |

| Voltage Range | 24 V DC ±20% |

| Current per Channel | 2 A (maximum continuous) |

| Short-Circuit Protection | Yes (auto-recovery) |

| Overvoltage Protection | Transient voltage suppression (TVS diodes) |

| Communication Interface | Serial (via controller backplane) |

| Operating Temperature | -20°C to +60°C |

| Mounting | DIN rail (TS 35/7.5 or TS 35/15) |

| Dimensions (W×H×D) | 36 mm × 125 mm × 100 mm |

| Certifications | CE, UL, cUL, IEC 61131-2 (PLC standard) |

ABB DO801

3. Advantages and Features

ABB DO801 excels in reliability and diagnostic capability. Each output channel includes LED status indicators for real-time fault detection, reducing troubleshooting time by up to 50% in complex systems. The module’s surge protection circuitry safeguards against voltage spikes caused by inductive loads, extending the lifespan of connected devices by 20% compared to non-protected alternatives. For example, in a packaging line application, DO801 reliably controlled pneumatic valves for 500,000 cycles without failure, demonstrating its durability in high-frequency switching scenarios. Additionally, its hot-swap functionality allows module replacement without powering down the system, minimizing downtime during maintenance.

4. Application Areas and Application Cases

Industry Applications:

- Manufacturing: Assembly lines, robotics, and machine tool control.

- Process Automation: Valve control in chemical plants, conveyor systems in mining.

- Building Automation: HVAC systems, lighting control, and access management.

Case Study: A pharmaceutical factory integrated ABB DO801 into its sterile filling line to manage solenoid valves and safety interlocks. The module’s isolation features prevented ground loops and signal interference, ensuring precise control of sterile fluid dispensing. Over two years, the line achieved a 99.8% uptime rate, with zero output-related failures, highlighting DO801’s critical role in mission-critical processes.

5. Competitive Comparison

Compared to standard digital output modules, ABB DO801 offers superior environmental tolerance and system-level integration. Its wide temperature range (-20°C to +60°C) and IP20 rating make it suitable for extreme industrial environments, while many competitors face performance degradation in high heat. The module’s native compatibility with ABB controllers reduces programming effort by 30%, as it leverages pre-defined function blocks in ABB’s Automation Builder software, unlike non-ABB modules that require custom driver development.

ABB DO801

6. Selection Recommendations

- Load Requirements: Ensure the module’s 2 A per-channel capacity matches the current draw of connected devices (e.g., solenoid valves, contactors).

- Environmental Needs: Prioritize DO801 for applications with voltage surges or frequent on/off cycles, such as motor control or hydraulic systems.

- System Redundancy: For critical processes, pair with ABB’s redundancy modules to create fail-safe configurations.

- Scalability: Use multiple DO801 modules in parallel for systems requiring more than 8 digital outputs, ensuring consistent performance across all channels.

7. Precautions

- Wiring: Separate output cables from high-voltage or signal cables to avoid EMI; use twisted-pair wiring for long runs (>50 meters).

- Voltage Verification: Confirm the correct supply voltage (24 V DC) before connecting to prevent damage from overvoltage.

- Heat Management: Install the module in a well-ventilated control cabinet, leaving at least 25 mm spacing between adjacent modules to prevent overheating.

- Maintenance: Regularly inspect LED status indicators for fault conditions (e.g., red light for short circuit) and test output functionality during scheduled shutdowns.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.