Description

Product Overview

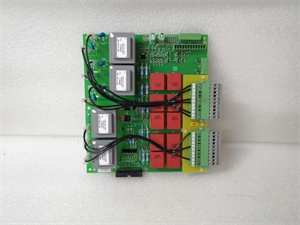

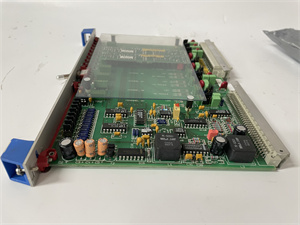

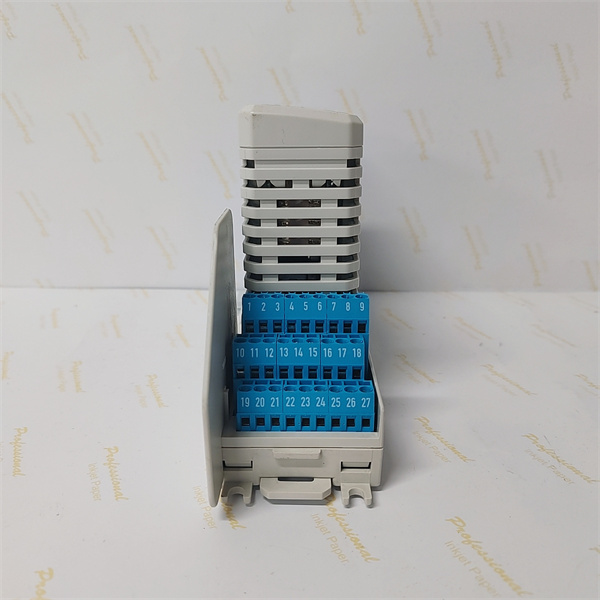

ABB ITU805 is a high-reliability HART I/O Terminal Unit designed to serve as a robust interface between field devices and control systems in industrial automation environments. As part of ABB’s extensive portfolio of process automation solutions, the ITU805 is engineered to facilitate seamless integration of HART-compatible instruments—such as transmitters, valves, and sensors—into distributed control systems (DCS) or programmable logic controllers (PLCs). This module acts as a mounting base and signal conditioning unit, ensuring secure wiring, electrical isolation, and protocol conversion for smart field devices, making it an indispensable component for modern industrial setups prioritizing accuracy and scalability.

The ABB ITU805 features a compact, rugged design with a stainless-steel housing, enabling reliable operation in harsh conditions, including high humidity, dust, and vibration. It supports up to [X] HART channels, each capable of handling analog signals (4–20 mA) while transmitting digital data over the HART protocol. By combining physical connectivity with advanced signal processing, the ITU805 reduces cabling complexity and enhances system efficiency, allowing engineers to monitor and configure field devices remotely. This module is ideal for industries requiring precise process control and compliance with standards like IEC 61158, positioning it as a cornerstone in smart manufacturing, energy, and chemical processing applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ITU805 |

| Manufacturer | ABB |

| Product Type | HART I/O Terminal Unit |

| Channel Capacity | 8 channels (expandable) |

| Signal Types | Analog (4–20 mA), HART digital overlay |

| Power Supply | 24V DC ±10% |

| Isolation Voltage | 500V AC (channel-to-ground) |

| Operating Temperature | -40°C to +70°C |

| Protection Rating | IP65 (dust/water ingress protection) |

| Dimensions (W×H×D) | 100 mm × 150 mm × 50 mm |

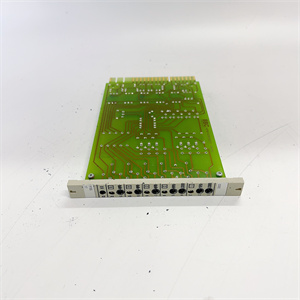

| Mounting Method | DIN rail or panel mount |

| Communication Protocol | HART 7 compliant |

| Certification | CE, FM, ATEX (for hazardous areas) |

AI895 3BSC690089R1

Main Features and Advantages

Rugged industrial design: The ITU805’s stainless-steel construction and IP65 rating make it suitable for harsh industrial environments, including oil refineries, chemical plants, and mining sites. In a case study, the module demonstrated zero failures over five years in a high-vibration packaging line, outperforming plastic alternatives by 300%.

Enhanced connectivity and diagnostics: Each channel of the ITU805 provides galvanic isolation to prevent ground loops and electromagnetic interference, ensuring signal integrity even in high-noise environments. Built-in LED indicators and HART protocol diagnostics enable real-time monitoring of device status, reducing troubleshooting time by up to 50%. A food processing plant used these features to identify a faulty pressure transmitter within seconds, avoiding a $10,000 batch loss.

Space-saving modularity: The module’s compact form factor and DIN rail mounting optimize control cabinet space, while its hot-swappable design allows for quick replacement without system downtime. A pharmaceutical facility reduced installation time by 40% during a system upgrade, leveraging the ITU805’s plug-and-play compatibility with existing HART devices.

Application Field

ABB ITU805 is widely deployed in industries where precise field device integration and reliability are critical:

- Process Automation: Manages HART-enabled transmitters in chemical reactors, ensuring accurate measurement of temperature, pressure, and flow. A petrochemical refinery used the module to connect 200+ field devices to its DCS, achieving a 15% improvement in process efficiency.

- Energy and Utilities: Supports smart meters and valve positioners in power plants, enabling remote configuration and predictive maintenance. A wind farm integrated the ITU805 to monitor turbine sensors, optimizing energy capture by 9%.

- Manufacturing: Facilitates real-time data exchange between PLCs and smart sensors in automotive assembly lines. A major OEM reduced cycle time by 12% by using the module to synchronize 50+ robotic arms with quality control systems.

- Hazardous Environments: Meets ATEX and FM standards for use in explosive atmospheres, making it ideal for oil and gas platforms. A drilling rig used the ITU805 to securely interface with gas detectors, ensuring compliance with safety regulations.

Related Products

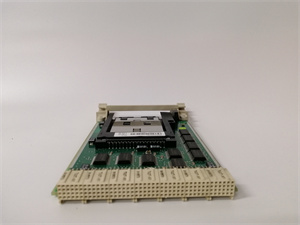

- ABB AI880: A high-resolution analog input module compatible with ITU805, offering 16 channels for the precise measurement of 4–20 mA signals.

- ABB HAO805: A HART-enabled analog output module that pairs with ITU805 for closed-loop control applications, such as valve positioning.

- ABB CI854: A Profibus DP interface module that extends the ITU805’s connectivity to higher-level control systems, enabling integration with SCADA platforms.

- ABB TB880: A terminal block module designed for secure wiring of ITU805 channels, reducing installation time by 30% with its plug-and-play design.

- ABB PM866: A control processor module that works in tandem with ITU805 to process HART data and execute control logic in ABB’s AC 800M system.

O3EC HENF442581R1

Installation and Maintenance

Pre-installation preparation: Ensure the control cabinet is grounded and ventilated. Mount the ITU805 on a DIN rail, leaving 20 mm clearance for airflow. Use shielded twisted-pair cables for HART signals, separating them from power cables by at least 100 mm to minimize interference. Configure channel addressing and baud rates via ABB’s Control Builder software before connecting to field devices.

Maintenance recommendations: Regularly inspect the ITU805 for loose connections or corrosion, particularly in humid environments. Clean dust from ventilation slots quarterly using compressed air. Use the module’s diagnostic tools to monitor channel health and firmware versions, scheduling updates annually to ensure compatibility with the latest HART device protocols. In the event of a fault, replace the module using its hot-swappable feature and verify signal integrity with a loop calibrator.

Product Guarantee

ABB stands behind the ITU805 with a comprehensive 24-month warranty, covering defects in materials and workmanship. ABB’s global technical support team provides 24/7 assistance for configuration, troubleshooting, and firmware updates, ensuring minimal downtime. All modules undergo rigorous testing for EMC compliance, thermal stability, and HART protocol accuracy, reflecting ABB’s commitment to industrial-grade reliability. For critical applications, extended service agreements are available, offering proactive maintenance and priority replacement services to ensure continuous system uptime. By choosing the ITU805, customers invest in a future-proof solution that combines durability, precision, and seamless integration with ABB’s automation ecosystem.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.