Description

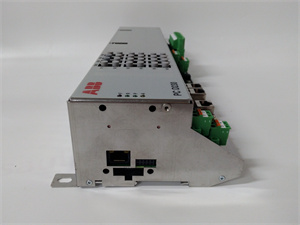

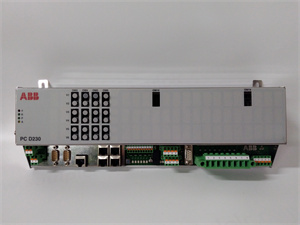

ABB PCD230A is a high-performance PLC module designed for industrial automation applications, offering advanced control capabilities and seamless integration with existing systems. This module is engineered to deliver reliable operation in demanding environments, making it a preferred choice for industries such as manufacturing, energy, and water treatment.

1. Product Description

The ABB PCD230A is a compact and versatile PLC module that serves as a core component in industrial control systems. It supports multiple communication protocols, enabling efficient data exchange between devices. With its robust design and advanced processing power, the PCD230A ensures stable performance even in harsh conditions, including temperature fluctuations and electromagnetic interference. Key features include modular expandability, user-friendly programming interfaces, and compatibility with ABB’s comprehensive automation suite.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC ±10% |

| Current Consumption | ≤500mA |

| Input/Output (I/O) | 16 digital inputs/16 digital outputs |

| Communication | Modbus RTU, Profibus DP, Ethernet/IP |

| Operating Temperature | -40°C to +70°C |

| Mounting | DIN rail or panel mount |

ABB PCD230A

3. Advantages and Features

- High Reliability: The PCD230A incorporates redundant power supply and error-checking mechanisms, achieving a Mean Time Between Failures (MTBF) of over 100,000 hours.

- Energy Efficiency: Its low power consumption reduces operational costs by up to 20% compared to older models.

- Ease of Integration: Pre-configured templates and plug-and-play functionality minimize setup time, while compatibility with ABB’s System 800xA simplifies system expansion.

4. Application Areas and Case Studies

The ABB PCD230A is widely used in:

- Manufacturing: Machine control and production line automation.

- Energy: Power plant monitoring and renewable energy systems.

- Water Treatment: Pump station control and wastewater management.

Case Study: A textile factory in China integrated the PCD230A into its production line, reducing downtime by 15% and improving energy efficiency by optimizing motor control.

5. Competitive Comparison

Compared to similar modules on the market, the PCD230A offers superior thermal management, allowing continuous operation at higher temperatures without performance degradation. Its built-in cybersecurity features also provide enhanced protection against potential threats.

ABB PCD230A

6. Selection Recommendations

- Compatibility: Ensure the module aligns with your existing PLC architecture (e.g., ABB AC500 series).

- Environment: Verify temperature and humidity requirements match the installation site.

- Scalability: Consider future expansion needs and select modules with sufficient I/O capacity.

7. Precautions

- Installation: Power off the system before connecting/disconnecting the module.

- Maintenance: Regularly inspect for dust accumulation and ensure proper ventilation.

- Safety: Follow ABB’s guidelines for electrostatic discharge (ESD) protection during handling.

山西鑫业达国际贸易有限公司 is your trusted partner for ABB PCD230A and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.