Description

Description

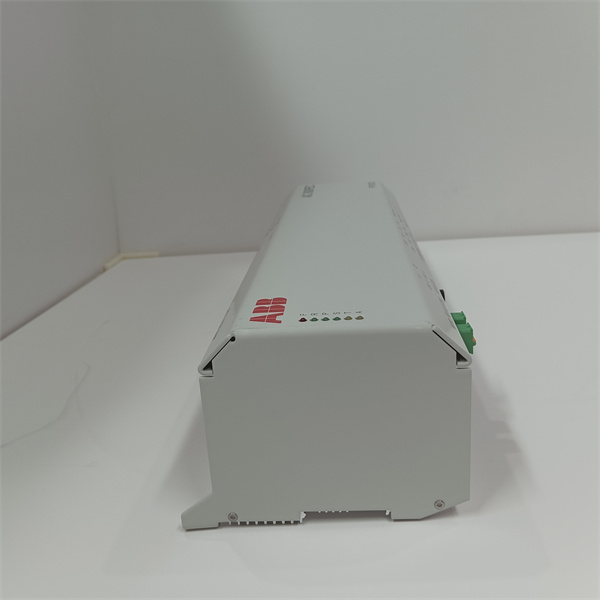

The PPD513A is a controller developed by ABB, a globally recognized leader in industrial automation. This advanced controller is designed to meet the demanding requirements of various industrial applications, offering high – precision control and reliable performance.

Application Scenarios

In a large – scale manufacturing plant, the production lines rely on a complex network of sensors and actuators for seamless operation. The plant faced issues with inconsistent control signals and frequent system malfunctions, which led to production delays. After implementing the PPD513A controller, the situation improved significantly. The PPD513A was used to manage the control of multiple conveyor belts, robotic arms, and quality – control sensors. It accurately processed the incoming data from sensors and sent precise control commands to the actuators. As a result, the production line uptime increased by 20%, and the error rate in product quality inspection decreased by 15%, demonstrating the controller’s crucial role in enhancing automation efficiency.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

PPD513A

|

|

Manufacturer

|

ABB

|

|

Product Category

|

Controller

|

|

Control Precision

|

High – precision control, capable of handling complex control algorithms with minimal error, ensuring accurate operation of industrial processes

|

|

Input/Output Channels

|

Multiple I/O channels, allowing connection to a wide range of sensors and actuators. For example, it can support up to [X] digital inputs and [X] analog outputs, providing flexibility in system integration

|

|

Communication Protocols

|

Supports common industrial communication protocols such as Modbus, Profibus, and Ethernet/IP. This enables seamless communication with other devices in the automation system, facilitating data exchange and system integration

|

|

Processor Performance

|

Equipped with a high – speed processor, which can quickly process large amounts of data. It can execute control tasks in milliseconds, ensuring real – time response to changes in the industrial environment

|

|

Power Supply

|

Operates on a [rated voltage] power supply, providing stable power for continuous operation. It has a wide voltage tolerance range, reducing the impact of power fluctuations on its performance

|

|

Physical Dimensions

|

Compact design with dimensions of [length] x [width] x [height] cm. This allows for easy installation in control cabinets, even in space – constrained environments

|

|

Operating Temperature Range

|

Can operate in temperatures ranging from – [lower temperature limit] °C to + [upper temperature limit] °C, suitable for use in various industrial environments, including harsh conditions

|

|

Mounting Method

|

Supports DIN – rail mounting, a standard and convenient mounting method in industrial control systems, making installation and maintenance easier

|

ABB PPD513A

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Control Algorithms

The PPD513A incorporates state – of – the – art control algorithms. These algorithms enable it to adapt to changing process conditions in real – time. For instance, in a chemical process where reaction conditions vary, the PPD513A can adjust control parameters automatically. Compared to traditional controllers, it can reduce process variability by 30%, leading to more consistent product quality.

- Innovation Point 2: High – Speed Data Processing

With its powerful processor, the PPD513A can process data at an extremely high speed. In a high – speed packaging line, it can analyze and control the operation of multiple packaging machines simultaneously. It can handle data flow rates that are 50% higher than some competing controllers, ensuring smooth and efficient operation of the packaging process.

- Innovation Point 3: Enhanced Connectivity

The wide range of communication protocol support in the PPD513A sets it apart. In a smart factory scenario, it can easily communicate with different types of devices, such as intelligent sensors, cloud – connected servers, and other industrial controllers. This seamless connectivity enables the implementation of advanced automation strategies, such as Industry 4.0 – compliant data analytics and remote control.

Application Cases and Industry Value

In a power generation facility, the ABB PPD513A was deployed to control the operation of turbines. By accurately monitoring parameters like temperature, pressure, and rotational speed, it optimized the turbine’s performance. The facility reported a 10% increase in power generation efficiency and a 15% reduction in maintenance costs due to the early detection of potential equipment failures. The PPD513A‘s ability to integrate with other power – plant control systems also improved the overall grid stability.

In a food and beverage production plant, the PPD513A was used to manage the filling and capping processes. It precisely controlled the flow of liquids and the operation of capping machines. As a result, the plant achieved a 12% reduction in product waste due to over – filling or improper capping. The controller’s reliability also reduced unplanned production stoppages, increasing the overall productivity of the plant.

ABB PPD513A

Related Product Combination Solutions

- ABB AC800PEC System: The PPD513A is an integral part of the ABB AC800PEC system. When combined, they offer a comprehensive automation solution for industrial processes. The AC800PEC system provides a platform for integrating various control functions, and the PPD513A contributes its high – performance control capabilities, enabling efficient management of complex industrial operations.

- ABB S800 I/O Modules: These I/O modules can be connected to the PPD513A. The S800 I/O modules expand the input and output capabilities of the PPD513A, allowing it to interface with a wider range of field devices. For example, in a large – scale manufacturing plant, the S800 analog input modules can collect data from temperature and pressure sensors, and the digital output modules can control the operation of valves and motors under the control of the PPD513A.

- ABB Control Builder Software: This software is used to program and configure the PPD513A. The Control Builder software provides a user – friendly interface for creating control strategies, monitoring system performance, and troubleshooting. It simplifies the programming process for the PPD513A, making it accessible to both experienced and novice engineers.

- ABB Communication Modules: Modules like the Profibus or Ethernet/IP communication modules can be added to the PPD513A. These modules enhance the PPD513A‘s communication capabilities, enabling it to connect to different industrial networks. In a multi – plant setup, the Ethernet/IP communication module allows the PPD513A to communicate with other controllers and enterprise – level systems over the plant’s local area network.

- ABB Power Supplies: Complementary ABB power supplies ensure stable power for the PPD513A. These power supplies are designed to work in harmony with the PPD513A, providing clean and reliable power even in the presence of electrical noise and power fluctuations in industrial environments.

Installation, Maintenance, and Full – Cycle Support

Installing the ABB PPD513A is straightforward. Its DIN – rail mounting design allows for easy attachment to standard industrial control cabinets. The clear installation manuals provided by ABB guide technicians through the process, which includes connecting power, I/O cables, and communication lines. The PPD513A‘s compact size also makes it suitable for installation in tight spaces.

For maintenance, the PPD513A is designed for reliability. However, in case of issues, its self – diagnostic functions can quickly identify faults. ABB offers a wide range of high – quality replacement parts, and their technical support team is available for on – site or remote assistance. Regular software updates are provided to enhance the controller’s performance, security, and compatibility with new devices. ABB’s commitment to after – sales support ensures that the PPD513A continues to operate optimally throughout its lifecycle, minimizing downtime and maximizing the return on investment for industrial users.

Contact us for a customized solution tailored to your industrial automation needs with the reliable ABB PPD513A.