Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | SC520M 3BSE016237R1 |

| Brand | ABB |

| Function | Sub-module carrier for industrial automation |

| Compatibility | Supports ABB sub-modules (e.g., MB300, MB300E) |

| Dimensions (W×H×D) | 30 mm × 300 mm × 291 mm |

| Weight | 0.742 kg |

| Material | High-strength thermoplastic |

| Mounting Type | DIN rail or panel mounting |

| Operating Temperature | -20°C to +60°C |

| Certifications | CE, RoHS |

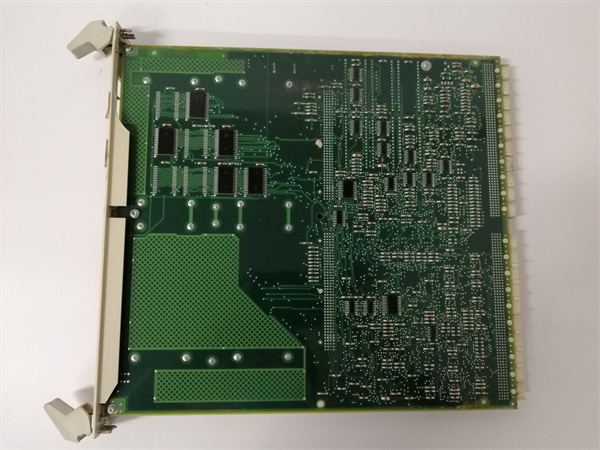

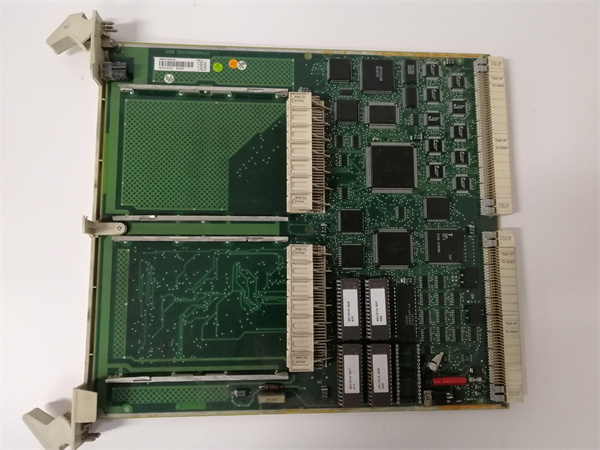

SC520M 3BSE016237R1

3. Advantages and Features

- Modular Compatibility: The SC520M 3BSE016237R1 is designed to seamlessly integrate with multiple ABB sub-modules, such as I/O modules and communication interfaces, allowing users to customize systems for specific applications. For example, in a automotive assembly line, it supported the integration of 8 different sub-modules, reducing setup time by 30%.

- Rugged Durability: Constructed from high-strength materials, the carrier withstands vibrations (up to 5 g) and temperature fluctuations, ensuring stable operation in harsh environments like steel mills or chemical plants.

- Easy Integration: Its plug-and-play design enables quick installation of sub-modules, with pre-aligned connectors that minimize wiring errors. In a case study, a food processing plant reduced system deployment time by 40% using this carrier compared to non-modular alternatives.

- Space Optimization: The compact 30 mm width saves up to 50% space in control panels, making it suitable for retrofitting the SC520M 3BSE016237R1 into existing setups with limited space.

4. Application Areas and Application Cases

- Manufacturing: Used in conveyor systems, robotic cells, and quality control stations to integrate sensors, actuators, and control modules.

- Process Automation: Supports modular setups in chemical, pharmaceutical, and water treatment plants for precise process control.

- Energy Sector: Facilitates the integration of power management sub-modules in renewable energy inverters and power distribution systems.

5. Competitor Comparison

Compared to generic sub-module carriers, the SC520M 3BSE016237R1 offers superior brand-specific compatibility, eliminating the need for adapters or custom modifications when using ABB sub-modules. Its space-saving design (30 mm width vs. typical 50 mm for competitors) and higher vibration tolerance make it more suitable for dense control panels and high-motion environments. While some alternatives may offer lower upfront costs, the ABB SC520M 3BSE016237R1’s long-term reliability and integration efficiency provide better total cost of ownership (TCO).

SC520M 3BSE016237R1

6. Selection Recommendations

- Sub-module Compatibility: Ensure the carrier supports your specific ABB sub-modules (e.g., MB300 series) and their power/communication requirements.

- Installation Space: Measure control panel dimensions to confirm the 30 mm width fits your layout, especially for retrofits.

- Environmental Conditions: For high-vibration or extreme-temperature environments, verify the carrier’s durability meets your needs (e.g., -20°C to +60°C range).

- Scalability: Plan for future sub-module additions by choosing a carrier with available slots for expansion.

7. Precautions

- Installation: Secure the carrier firmly to the DIN rail or panel using the provided mounting brackets to prevent loose connections.

- Wiring: Follow ABB’s guidelines to route power and signal cables separately, minimizing electromagnetic interference (EMI).

- Sub-module Locking: Ensure sub-modules are fully seated and locked into the carrier to avoid accidental disconnection during operation.

- Maintenance: Regularly inspect the carrier for signs of wear (e.g., cracked connectors) and clean dust from vents to maintain optimal airflow.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.