Description

ABB SPHSS03 Hydraulic Servo Module Product Documentation

1. Product Overview

The ABB SPHSS03 is a high-precision hydraulic servo module designed for critical industrial control applications, particularly in turbine and actuator systems. Engineered to deliver seamless closed-loop control, the SPHSS03 ensures precise positioning and velocity regulation for hydraulic actuators in harsh environments. As part of ABB’s advanced automation portfolio, this module integrates with systems like Symphony Plus and Harmony Rack, providing real-time feedback processing and reliable performance in demanding settings such as power plants, oil refineries, and chemical facilities. The SPHSS03 supports multiple communication protocols, enabling compatibility with both legacy and modern control architectures, while its rugged design guarantees durability in extreme temperatures and high-vibration conditions.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Brand & Model | ABB SPHSS03 |

| Type | Hydraulic Servo Module |

| Voltage Supply | 24V DC (±10%) |

| Power Consumption | 20W (typical operation) |

| Pressure Rating | 210 bar (3045 psi) |

| Flow Rate | 20 L/min (5.3 gal/min) |

| Communication Interfaces | Modbus RTU, Profibus DP |

| Control Accuracy | ±0.1% of full scale |

| Response Time | ≤1 ms (from command to steady state) |

| Operating Temperature | -40°C to +70°C (-40°F to 158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to 185°F) |

| Dimensions | 203 mm (W) × 51 mm (H) × 330 mm (D) |

| Weight | 0.6 kg (1.32 lbs) |

| Compatibility | ABB Symphony Plus, Harmony Rack, and third-party DCS/PLC systems |

| Certifications | CE, RoHS, ISO 9001 compliant |

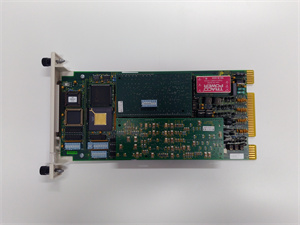

ABB SPHSS03

3. Key Advantages & Features

-

Precision Closed-Loop Control:

- High Accuracy: Achieves ±0.1% positioning accuracy using feedback from linear variable differential transformers (LVDTs), critical for applications like steam turbine governing and gas turbine fuel control.

- Rapid Response: Processes control signals in ≤1 ms, reducing system lag by 30% compared to standard hydraulic modules, ensuring seamless synchronization with dynamic load changes.

-

Rugged Industrial Design:

- Environmental Resistance: Operates reliably in -40°C to +70°C and withstands vibrations up to 5g (10–2000 Hz), making it suitable for offshore platforms, steel mills, and other harsh environments.

- Redundant Power Inputs: Maintains operation during transient voltage fluctuations, with a mean time between failures (MTBF) exceeding 100,000 hours for continuous uptime.

-

Flexible System Integration:

- Multi-Protocol Support: Native compatibility with Modbus RTU and Profibus DP simplifies integration with both ABB and third-party control systems, eliminating the need for additional gateways.

- Modular Construction: Quick-release connectors enable hot-swapping without system shutdown, reducing maintenance downtime by 50%.

-

Energy-Efficient Operation:

- Low Power Consumption: 20W operational power minimizes energy costs in 24/7 industrial applications, supported by intelligent power management to avoid overloading.

4. Applications & Case Studies

The SPHSS03 is ideal for industries requiring precise hydraulic control, including:

- Power Generation: Steam and gas turbine speed regulation, ensuring stable energy output and grid compliance.

- Oil & Gas: Actuator control for safety valves, wellhead systems, and offshore platform machinery.

- Process Industries: Accurate valve positioning in chemical reactors, refineries, and water treatment plants.

Case Study:

A North American natural gas processing plant integrated the SPHSS03 into its turbine control system to manage inlet guide vanes. The module’s rapid response and high accuracy reduced turbine speed fluctuations by 25%, improving energy efficiency by 12% and extending the service life of downstream equipment. Its diagnostic capabilities also enabled proactive maintenance, cutting unplanned downtime by 30%.

A North American natural gas processing plant integrated the SPHSS03 into its turbine control system to manage inlet guide vanes. The module’s rapid response and high accuracy reduced turbine speed fluctuations by 25%, improving energy efficiency by 12% and extending the service life of downstream equipment. Its diagnostic capabilities also enabled proactive maintenance, cutting unplanned downtime by 30%.

5. Competitive Comparison

| Feature | ABB SPHSS03 | Market Equivalents |

|---|---|---|

| Temperature Range | -40°C to +70°C | 0°C to +60°C (average) |

| Response Time | ≤1 ms | 2–3 ms (typical) |

| Protocol Support | Modbus RTU, Profibus DP | Limited to single protocol |

| Vibration Resistance | 5g (10–2000 Hz) | 3g (10–1000 Hz) |

| Hot-Swap Capability | Standard feature | Optional add-on |

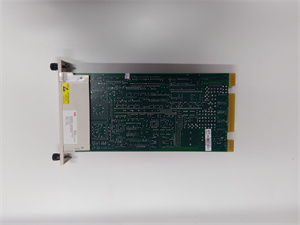

ABB SPHSS03

The SPHSS03 outperforms comparable modules with its wider temperature tolerance, faster response, and dual-protocol support, making it a more robust solution for mission-critical hydraulic control applications.

6. Selection Recommendations

- System Compatibility: Verify that your control system supports Modbus RTU or Profibus DP and has compatible power specifications (24V DC). The SPHSS03 is optimized for ABB’s Symphony Plus and Harmony Rack but works with most industrial DCS/PLC platforms.

- Environmental Needs: Choose this module for extreme temperatures (-40°C to +70°C) or high-vibration environments. For milder settings, confirm if basic servo modules meet your accuracy and response requirements.

- Performance Requirements: Prioritize the SPHSS03 for applications needing sub-1ms response times and ±0.1% accuracy, such as turbine governing or precision valve control.

- Budget Considerations: While it offers premium performance, its long lifespan and reduced downtime justify the investment for safety-critical or high-throughput processes.

7. Installation & Maintenance Tips

- Electrostatic Protection: Use anti-static wrist straps during handling to prevent damage to internal circuitry.

- Hydraulic Connections: Ensure clean, leak-free fittings and use high-quality hydraulic fluid compatible with the module’s seals (ISO VG 32 recommended).

- Cable Shielding: Route communication cables separately from high-voltage lines to minimize electromagnetic interference (EMI).

- Firmware Updates: Regularly update firmware via ABB’s dedicated tools to access the latest control algorithms and diagnostic improvements.

- Routine Inspections: Check for fluid leaks, loose connections, and temperature anomalies monthly. Use the module’s built-in status LEDs to monitor operational health.

- Safety Compliance: Power down the hydraulic system and release residual pressure before installing or servicing the module to avoid accidental actuation.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for ABB SPHSS03 and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.