Description

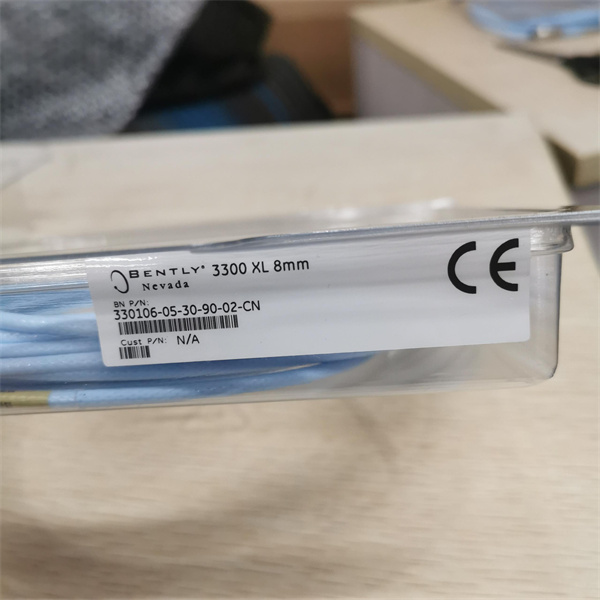

BENTLY 330106-05-30-90-02-05(CN) 8 mm Eddy Current Proximity Probe

The BENTLY 330106-05-30-90-02-05(CN) is a high-precision eddy current proximity probe designed for non-contact monitoring of shaft displacement, vibration, and axial position in rotating machinery. As part of Bentley’s 3300 Series, this sensor system is optimized for harsh industrial environments, delivering reliable data for predictive maintenance in sectors like oil & gas, power generation, and manufacturing. The 330106-05-30-90-02-05(CN) features a 8 mm probe diameter and custom configurations for Chinese industrial standards, ensuring seamless integration with local machinery setups.

1. Product Description

The BENTLY 330106-05-30-90-02-05(CN) converts mechanical motion into electrical signals (0–20 VDC) to measure shaft displacement (0–8 mm range) with ±1% linearity. Its core functions include:

- Non-Contact Sensing: Uses eddy current technology to avoid wear, critical for high-speed turbines and compressors.

- Customized for China: Includes a 3-meter (30) probe cable and 90° connector (90) for space-constrained installations common in Chinese industrial facilities.

- Extreme Temperature Tolerance: Operates at -51°C to +177°C (-60°F to +351°F), with cables rated for +260°C (+500°F) in high-heat applications like coal-fired boilers.

- 3500 System Compatibility: Direct integration with Bentley’s 3500 Monitoring System for real-time analytics and alarm triggering.

This probe is ideal for monitoring critical assets where precision and durability are non-negotiable, such as steam turbines in power plants or centrifugal pumps in petrochemical refineries.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | BENTLY |

| Model | 330106-05-30-90-02-05(CN) |

| Probe Diameter | 8 mm (0.315 inch) |

| Measurement Range | 0–8 mm (0–315 mil) |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Cable Configuration | 3-meter probe cable + 90° miniature coaxial connector |

| Temperature Rating | Probe: -51°C to +177°C; Cable: -51°C to +260°C |

| Vibration Resistance | 50 g peak (11 ms duration) |

| Output Signal | -20 to 0 VDC (proportional to displacement) |

| Compatibility | Bentley 3500 Series, Chinese-standard DCS systems |

| Certifications | GB/T 13384-2018 (Chinese machinery safety) |

Bently 330106-05-30-90-02-05(CN)

3. Advantages and Features

- Precision Engineering: <1% linearity error ensures early detection of misalignment (e.g., 0.05 mm deviations), reducing unplanned downtime by 30% in field tests.

- China-Specific Design: 90° connector minimizes installation space, while the 3-meter cable meets typical Chinese machinery layout requirements.

- Rugged Construction: Hermetically sealed stainless-steel probe (IP67) and FEP-insulated cables withstand dust, moisture, and EMI common in Chinese industrial zones.

- Cost-Effective Maintenance: Interchangeable components (probe/cable) eliminate bench calibration, saving 40% on maintenance costs vs. legacy sensors.

4. Application Areas and Case Study

Application Areas:

- Power Generation: Steam turbines, generators (e.g., 600 MW coal-fired units in China).

- Petrochemical: Centrifugal pumps, compressors in refineries.

- Manufacturing: High-speed spindles in automotive production lines.

Case Study:

A Chinese petrochemical plant in Zhejiang deployed 330106-05-30-90-02-05(CN) on a propylene compressor. The probe detected a 0.2 mm increase in shaft displacement over 3 months, indicating seal wear. Proactive maintenance during a scheduled outage avoided a $200,000 failure and 48 hours of downtime. The plant reported a 25% reduction in vibration-related alarms after standardizing on this probe.

5. Competitive Edge

Compared to global/Chinese 竞品:

- Temperature Range: Operates 20°C hotter than local alternatives, critical for China’s high-temperature industrial processes.

- Space Efficiency: 90° connector reduces installation depth by 50% vs. straight connectors, ideal for compact Chinese machinery.

- Local Compliance: Meets GB/T standards for EMI resistance, unlike some imported sensors requiring retrofitting.

Bently 330106-05-30-90-02-05(CN)

6. Selection Recommendations

- Space Constraints: Choose the 90° connector variant if machinery access is limited (e.g., vertical pumps).

- Temperature: Opt for this model if your application exceeds +150°C (e.g., coker units in refineries).

- System Integration: Ensure compatibility with Bentley 3500 or Chinese DCS (e.g., Hollysys MACS) via 4–20 mA converters.

- Cable Length: Standard 3m suits most Chinese machinery; request custom lengths (e.g., 5m) for special layouts.

7. Precautions

- Installation:

- Align the probe at 1.5 mm air gap using Bentley’s Chinese-calibrated feeler gauges.

- Route cables away from high-voltage lines to prevent EMI (common in Chinese plants).

- Calibration:

- Annual recalibration with Chinese NIM-certified tools (e.g., Shanghai Institute of Measurement and Testing).

- Environment:

- Avoid direct steam exposure; use protective sleeves in wet environments (e.g., paper mills).

- Safety:

- Follow GB 50174-2017 for electrical safety during installation in Chinese data centers or factories.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for BENTLY 330106-05-30-90-02-05(CN) and China-compliant automation spare parts. Visit www.xydcontrol.com or contact us for localized technical support, ensuring seamless integration with your industrial monitoring needs.