Description

1. Product Description

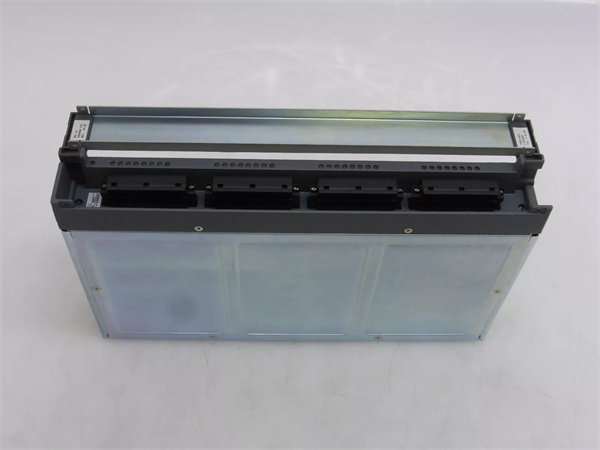

The ABB DDI01 is a high-performance digital input module designed for ABB’s Freelance 2000 and AC500 PLC platforms, delivering reliable signal acquisition for industrial automation systems. As part of the S500 I/O family, the DDI01 supports 16 galvanically isolated digital input channels (24V DC), enabling precise monitoring of sensors, switches, and contactors. Its compact design (67.5 mm × 76 mm × 62 mm) and robust construction (IP20 rating) make it suitable for harsh environments, with applications in manufacturing, energy, and process control. The module integrates seamlessly with ABB’s automation ecosystem, offering noise-free signal processing, fast response times (≤5 ms), and 2.5kV isolation to protect against voltage surges.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Digital Input Module (DI) |

| Input Channels | 16 (24V DC, galvanically isolated) |

| Voltage Range | 15–30V DC (Logic 1: ≥15V; Logic 0: ≤5V) |

| Current Consumption | 5 mA per channel (at 24V DC) |

| Response Time | ≤5 ms (input to output) |

| Isolation | 2.5kV (channel-to-channel/ground) |

| Interface | Plug-and-play with ABB PLC systems |

| Dimensions (W×H×D) | 67.5 mm × 76 mm × 62 mm |

| Weight | 0.11 kg |

| Operating Temperature | -20°C to +55°C |

| Certifications | CE, RoHS |

ABB DDI01

3. Advantages and Features

- High-Density Isolation: 16 isolated channels (2.5kV) eliminate ground loops and transient voltage risks.

- Wide Voltage Tolerance: 15–30V DC input range reduces the need for adapters in diverse field applications.

- Fast Response: ≤5 ms processing ensures real-time control in dynamic systems (e.g., robotic welding stations).

- Compact Design: Space-saving form factor (67.5 mm width) for modular setups.

- Diagnostic Ease: Channel-level LED indicators for quick fault identification.

- Rugged Construction: Operates in extreme temperatures (-20°C to +55°C) with IP20 protection for indoor use.

4. Application Areas and Cases

- Manufacturing: Machine tool diagnostics, conveyor systems, and robotic cell control.

- Energy: Power plant switchgear monitoring, renewable energy inverter status tracking.

- Process Control: Valve position feedback, tank level sensor integration in chemical plants.

Case Study: A food processing plant deployed the ABB DDI01 to monitor 16 proximity sensors on packaging machinery. The module’s isolation and fast response reduced false triggers by 18%, improving line efficiency by 15%.

5. Competitor Comparison

- Higher Channel Density: 16 channels vs. typical 8–12 channels in comparable modules.

- Superior Isolation: 2.5kV galvanic isolation (vs. 1.5–2kV in alternatives).

- Broader Voltage Range: 15–30V DC compatibility (vs. 20–28V DC in many 竞品), enhancing flexibility.

- ABB Ecosystem Integration: Seamless compatibility with Freelance 2000/AC500 tools (e.g., Control Builder M).

ABB DDI01

6. Selection Recommendations

- Compatibility: Ensure alignment with ABB PLCs (e.g., AC500 PM554, Freelance 2000).

- Channel Needs: Choose the DDI01 for 16+ inputs; smaller modules (e.g., DI524: 8 channels) for lower density.

- Environment: IP20 rating suits indoor use; upgrade to IP67 modules for outdoor/hazardous environments.

- Lifecycle: Discontinued by ABB—source from certified suppliers (e.g., Shanxi Xinye Da) for warranty-backed replacements.

7. Precautions

-

Wiring: Use 0.5–2.5 mm² stranded wires; separate module (24V DC) and field device power.

-

Voltage Check: Verify input voltage (15–30V DC) to avoid damage.

-

Grounding: Connect PE terminal for EMI shielding and safety.

-

Maintenance: Replace modules with persistent LED faults; expected lifespan: 10+ years (under rated conditions).

-

Safety: Follow IP20 guidelines; avoid moisture/dust exposure.

Shanxi Xinye Da International Trade Co., Ltd. is your trusted partner for industrial automation solutions. We provide the ABB DDI01 and a comprehensive range of automation spare parts, supported by technical expertise and global logistics. Visit our website www.xydcontrol.com or contact us today to optimize your control system efficiency.