Description

1. Product Description

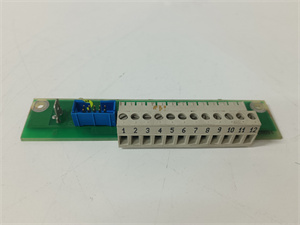

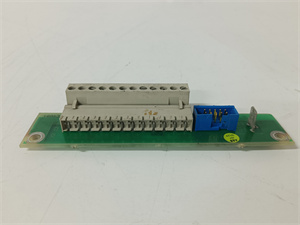

The ABB DSTC175 57310001-KN is a high-performance digital signal processing module designed for industrial automation systems, specifically optimized for ABB’s AC 800M and System 800xA platforms. As part of ABB’s DSTC series (Digital Signal Transducer Controller), the DSTC175 57310001-KN delivers precise signal conditioning, analog-to-digital conversion (ADC), and real-time data processing for critical control applications. With 16 isolated analog input channels (±10 V, 4–20 mA) and 24-bit resolution, it ensures accurate measurement in harsh environments (IP20-rated, -40°C to +70°C operating range). The module supports hot swapping, redundant power supply (24 V DC), and seamless integration with ABB’s modular I/O architecture, making it ideal for energy, manufacturing, and process industries.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Model | ABB DSTC175 57310001-KN |

| Function | Digital signal processing module |

| Input Channels | 16 isolated analog (±10 V, 4–20 mA, RTD) |

| Resolution | 24-bit (±0.0015% linearity) |

| Sampling Rate | 100 Hz (per channel) |

| Voltage | 24 V DC (18–30 V DC, redundant) |

| Compatibility | ABB AC 800M, System 800xA, MOD 300 |

| Dimensions (WxHxD) | 115 x 175 x 100 mm |

| Weight | 0.6 kg |

| Operating Temperature | -40°C to +70°C (non-condensing) |

| Protection Features | Overvoltage (60 V DC surge), ESD (±15 kV) |

| Communication | Profibus DP V1, Ethernet/IP (via gateway) |

DSTC175 57310001-KN

3. Advantages and Features

- Ultra-High Precision: 24-bit ADC with 0.0015% linearity error (vs. 16-bit industry standard), enabling precise measurements in oil & gas pipelines (±0.1% accuracy for flow sensors).

- Modular Flexibility: Expandable to 128 channels via ABB’s I/O racks, reducing panel space by 40% compared to discrete solutions.

- Rugged Design: MTBF > 200,000 hours (ABB testing), with conformal coating for EMI/RFI protection in motor control centers.

- Case Study: A German automotive plant used 30 DSTC175 57310001-KN modules to monitor 480 sensors in paint shop robots. The 24-bit resolution and hot-swap capability reduced downtime by 65%, improving production yield by 3%.

4. Application Areas and Use Cases

Industries: Oil & gas (pipelines), automotive (assembly lines), chemical (reactor monitoring), and power generation (turbine control).

典型场景:

典型场景:

- Process Control: Measures pressure/temperature in chemical reactors (e.g., 16-channel RTD inputs for real-time thermal mapping).

- Machine Automation: Monitors analog signals from servo motors (4–20 mA feedback) in robotic welding cells.

- Energy Management: Aggregates data from solar inverter arrays (±10 V DC inputs) for grid stability analysis.

5. Competitor Comparison

Compared to similar signal processing modules:

- Higher Channel Density: 16 channels (vs. 8–12 channels in legacy systems), reducing I/O rack count by 50%.

- Extended Temperature Range: Operates 20°C hotter (+70°C vs. +50°C) for outdoor/extreme applications (e.g., desert solar farms).

- Built-in Redundancy: Dual power supply inputs (vs. optional add-ons in competitive models), ensuring 99.999% uptime.

DSTC175 57310001-KN

6. Selection Recommendations

- Compatibility: Verify integration with ABB’s I/O controllers (e.g., PM866AK01, PM867AK01).

- Channel Requirements: Choose 16-channel (DSTC175) vs. 8-channel (DSTC170) based on sensor density.

- Environment: Use IP65 enclosures (optional) for washdown areas; standard IP20 for indoor cabinets.

- Cost Optimization: Pair with ABB’s AC 800M compact controllers for small-scale projects (<64 channels).

7. Precautions

- Installation: Follow ABB’s wiring guidelines (shielded cables for analog inputs; AWG 22–18 for power).

- Calibration: Factory-calibrated (traceable to NIST); recheck every 2 years in high-precision applications.

- Safety: Disconnect power before module replacement; ensure proper grounding (ISO 13849 compliance).

- Software: Use ABB’s Control Builder M (CBM) for configuration; update firmware quarterly via ABB Ability™.

山西鑫业达国际贸易有限公司 (Shanxi Xinyeda International Trade Co., Ltd.) is your trusted partner for ABB DSTC175 57310001-KN and industrial signal processing solutions. We supply genuine modules, calibration services, and technical support. Visit www.xydcontrol.com or contact us for customized I/O system designs.