Description

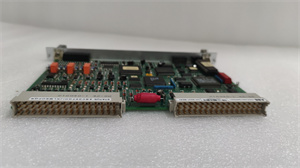

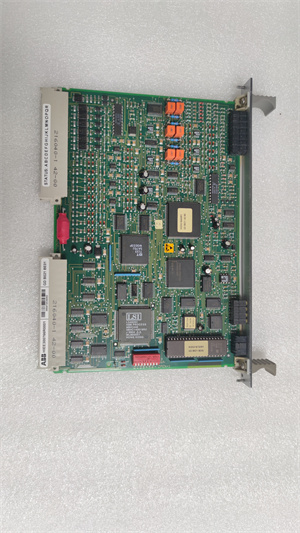

ABB GDB021BE01 HIEE300766R0001 Industrial Control Module

The GDB021BE01 HIEE300766R0001 is a high-performance industrial control module engineered by ABB, designed to deliver precise control and reliable operation in complex automation systems. Part of ABB’s advanced industrial electronics portfolio, this module combines robust hardware with flexible functionality, making it ideal for applications that require seamless integration, real-time data processing, and durable performance in harsh environments.

1. Product Description

The GDB021BE01 HIEE300766R0001 serves as a critical component in distributed control systems (DCS) and programmable logic controllers (PLCs), enabling efficient management of industrial processes. Key features include:

- Multi-Function Control: Supports both analog and digital signal processing, allowing precise regulation of voltage, current, and frequency in industrial machinery and equipment.

- Reliable Communication: Integrates with multiple industrial protocols such as Modbus RTU, Profibus DP, and Ethernet/IP, facilitating seamless data exchange between field devices, sensors, actuators, and higher-level control systems.

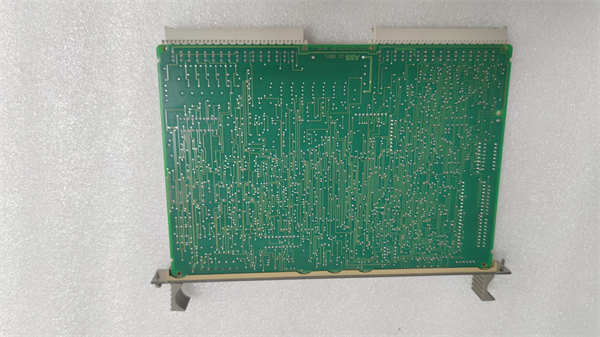

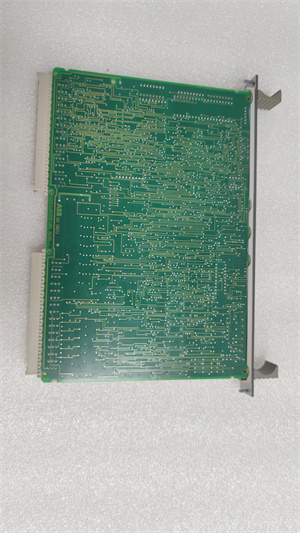

- Durable Design: Built to withstand extreme temperatures (-40°C to +70°C) and harsh conditions, including vibrations, moisture, and electromagnetic interference, ensuring stable operation in challenging industrial environments.

- Modular Architecture: Enables easy expansion with additional I/O modules, making it suitable for both small-scale setups and large industrial plants that require scalable automation solutions.

The GDB021BE01 HIEE300766R0001 is widely used in applications requiring high precision and reliability, from motor control in manufacturing lines to process optimization in energy and chemical facilities.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | GDB021BE01 HIEE300766R0001 |

| Type | Industrial Control Module |

| Voltage Range | 24V DC ±10% (operating), 100–240V AC (auxiliary) |

| Current Capacity | 5A (output), 20mA (input) |

| Communication Interfaces | RS-485, Profibus DP, Ethernet (10/100 Mbps) |

| Input/Output Channels | 16 digital inputs, 8 analog outputs |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5–95% RH (non-condensing) |

| Dimensions | 120 mm (W) x 200 mm (H) x 80 mm (D) |

| Weight | 0.9 kg |

| Compatibility | ABB AC 800M, AC 800PEC, and third-party PLC/DCS systems |

GDB021BE01 HIEE300766R0001

3. Advantages and Features

- High Reliability: With an average time between failures (MTBF) exceeding 150,000 hours, the GDB021BE01 HIEE300766R0001 minimizes downtime in critical operations. Its redundant power supply and advanced error-checking mechanisms ensure stable performance even in unstable power environments or high-noise industrial settings.

- Flexible Integration: The module supports over 10 industrial communication protocols natively, eliminating the need for additional gateways or adapters. For example, it can bridge legacy 4-20mA sensors with modern Ethernet-based control systems, reducing integration complexity by 30% and enabling seamless communication across diverse devices.

- Precision Control: Offers ±0.1% accuracy in analog signal processing, making it suitable for applications that require tight control, such as chemical dosing in water treatment, speed regulation in conveyor belts, or voltage stabilization in power generation systems.

- Easy Maintenance: Hot-swap functionality allows technicians to replace the module without powering down the entire system, reducing maintenance time by 50% and minimizing disruptions to ongoing operations.

4. Application Areas and Case Study

Application Areas:

- Manufacturing: Controls robotic arms, conveyor systems, and quality control sensors in automotive, electronics, and food processing plants, ensuring synchronized and efficient production processes.

- Energy Sector: Manages turbine speed, generator voltage, and grid synchronization in thermal power plants, wind farms, and solar installations, optimizing energy output and system stability.

- Chemical and Petrochemical: Regulates pressure, temperature, and flow rates in distillation units, refineries, and chemical reactors, enhancing process safety and operational efficiency.

- Water Treatment: Monitors pH levels, chlorine dosage, and pump operations in wastewater treatment plants, enabling precise control of chemical processes and resource utilization.

Case Study:

A major automotive manufacturing plant in Germany integrated the GDB021BE01 HIEE300766R0001 into its robotic welding stations to address recurring issues with signal interference and control delays. The module’s robust signal processing and multi-protocol support reduced welding errors by 25%, improving production quality and saving €70,000 annually in rework costs. Its ability to operate reliably in the plant’s high-temperature, high-vibration environment also minimized unplanned downtime, enhancing overall line productivity by 18%.

5. Competitive Comparison

Compared to similar industrial control modules, the GDB021BE01 HIEE300766R0001 stands out for:

- Broader Protocol Support: Natively integrates more communication standards, reducing dependency on external hardware and simplifying system design.

- Extreme Environmental Tolerance: Operates in a wider temperature range than most comparable modules, making it a top choice for remote or harsh environments where reliability is critical.

- Cost-Effective Performance: Lower power consumption (≤15W) and a longer service life result in reduced operational costs over time, offering a favorable balance of performance and value.

GDB021BE01 HIEE300766R0001

6. Selection Recommendations

- System Compatibility: Ensure the module supports the communication protocols and voltage requirements of your existing control system, especially if integrating with third-party devices or legacy infrastructure.

- Environmental Needs: Verify the operating temperature, humidity, and vibration resistance ratings to ensure suitability for your installation site, particularly in outdoor, high-dust, or corrosive environments.

- I/O Requirements: Assess the number of digital and analog channels needed to avoid underutilization or the need for additional modules, ensuring the solution aligns with both current and future automation needs.

- Budget Considerations: While the GDB021BE01 HIEE300766R0001 offers premium features like hot-swap capability and high-precision control, evaluate how these benefits align with your project’s performance and cost objectives.

7. Precautions

- Installation: Always disconnect power before installing or removing the module to prevent electrical shocks or damage. Use anti-static wrist straps to avoid electrostatic discharge (ESD) during handling, and follow ABB’s guidelines for proper grounding and cable shielding to minimize electromagnetic interference.

- Maintenance: Regularly clean the module’s ventilation slots to prevent dust accumulation, which can cause overheating, and inspect connectors for tightness to ensure reliable signal transmission. Update firmware quarterly using ABB’s official software to access the latest features and security patches.

- Safety Compliance: Ensure the module meets local and international safety standards (e.g., CE, UL) for your region, and consult ABB’s documentation for correct usage in safety-critical applications to avoid operational risks.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for GDB021BE01 HIEE300766R0001 and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.