Description

Product Overview

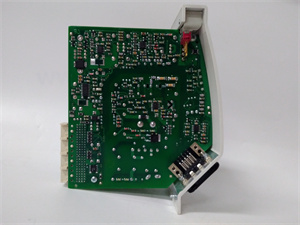

The ABB KUC720AE101 3BHB003431R0101 3BHB000652R0101 is a high-performance robot controller module designed for ABB’s advanced robotic systems, serving as the central nervous system for industrial robots in manufacturing, logistics, and assembly applications. As part of the IRC5 Controller series, this module integrates motion control, safety logic, and communication capabilities into a compact unit, enabling precise coordination of robotic arms (e.g., IRB 6700, IRB 1200) with sub-millimeter accuracy. The KUC720AE101 variant, paired with 3BHB003431R0101 (CPU module) and 3BHB000652R0101 (I/O interface), delivers deterministic performance for real-time control in high-speed pick-and-place, welding, and inspection tasks.

Engineered with a dual-core ARM processor and 2 GB RAM, the 3BHB003431R0101 ensures rapid execution of complex robot trajectories (up to 1,000 motion commands per second) while the 3BHB000652R0101 provides 32 digital I/O channels for seamless integration with sensors, grippers, and conveyor systems. The module supports ABB’s RobotStudio® software for offline programming and simulation, reducing commissioning time by up to 50% in automotive assembly lines. Positioned as a scalable solution, the KUC720AE101 series enables multi-robot coordination in collaborative cells, with built-in safety features (e.g., SafeMove2) compliant with ISO 10218-1/2 standards.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | KUC720AE101 3BHB003431R0101 3BHB000652R0101 |

| Manufacturer | ABB |

| Product Type | Robot Controller Module (IRC5 Platform) |

| Processor | Dual-core ARM Cortex-A15 @ 1.5 GHz |

| Memory | 2 GB RAM, 8 GB Flash |

| Supported Robots | IRB 1200 to IRB 8700 series |

| Motion Control Accuracy | ±0.02 mm (for small robots), ±0.1 mm (heavy-duty) |

| Communication Interfaces | Ethernet/IP, PROFINET, USB 3.0, RS-485 |

| Safety Features | SafeMove2 (SIL 3), STO, SS1 (EN 50155) |

| Power Supply | 24 V DC (18–30 V DC, 500 mA) |

| Operating Temperature | 0°C to +45°C (with forced cooling) |

| Dimensions (W×H×D) | 300 mm × 200 mm × 150 mm |

| Mounting Method | Rack-mounted (controller cabinet) |

| Certification | CE, UL, ISO 10218, IEC 61508, RoHS |

B5EEd HENF105082R4

Main Features and Advantages

Ultra-Precise Motion Control

The KUC720AE101 leverages ABB’s TrueMove and QuickMove technologies to ensure smooth, vibration-free motion even at high speeds (up to 5 m/s). In an electronics assembly plant, this enables robotic arms to place micro-components (e.g., 01005 resistors) with ±0.01 mm accuracy, minimizing defects in PCBA processes. The 3BHB003431R0101’s real-time operating system (RTSOS) guarantees deterministic cycle times (<1 ms), critical for synchronized pick-and-place with high-speed conveyors.

Advanced Safety and Collaboration

The built-in SafeMove2 suite allows safe human-robot collaboration by monitoring robot speed, position, and force in real time. For example, in a food packaging line, the module reduces robot speed when an operator approaches, enabling seamless shared workspaces without physical barriers. The 3BHB000652R0101’s fail-safe digital outputs support emergency stop circuits (STO) with <20 ms response time, ensuring compliance with strict safety regulations in pharmaceutical manufacturing.

Scalability and Ease of Integration

The module supports up to 4 robots per controller and 1,000 I/O points via expansion modules, making it suitable for complex production lines. Its Plug-and-Play compatibility with ABB’s FlexPendant and IRC5 I/O boards simplifies integration with third-party devices like vision systems (e.g., ABB’s PickMaster 5) or custom grippers. In a logistics warehouse, multiple KUC720AE101 units can coordinate a fleet of palletizing robots, optimizing throughput by 20% through synchronized task allocation.

Application Field

The ABB KUC720AE101 series is indispensable in industries demanding high-precision robotic automation:

- Automotive Manufacturing: Controls spot welding robots in body-in-white lines, achieving 5,000 welds per hour with 99.9% repeatability. The module’s PROFINET connectivity enables real-time data exchange with Siemens PLCs for seamless production tracking.

- Electronics and Semiconductors: Manages ultra-fine assembly robots in chip packaging, where the 3BHB003431R0101’s low-latency processing ensures precise alignment of wire bonders (±1 μm accuracy).

- Food and Beverage: Orchestrates pick-and-place robots in dairy packaging, handling fragile glass bottles with gentle motion profiles (≤0.5 m/s² acceleration) to prevent damage. The module’s IP20 rating and food-grade lubrication compatibility meet EHEDG standards.

- Aerospace: Powers collaborative robots in aircraft assembly, performing tasks like riveting and sealant application in confined spaces. The SafeMove2 feature allows engineers to work alongside robots during prototype testing, reducing manual labor by 30%.

Related Products

- ABB KUC710AE101: A 入门级 variant with single-core processing, suitable for small robots (e.g., IRB 1100) in simple pick-and-place tasks.

- ABB 3BHB003432R0101: A higher-performance CPU module (4-core, 4 GB RAM) for heavy-duty robots (e.g., IRB 8700) in foundries or heavy machinery assembly.

- ABB 3BHB000653R0101: A 64-channel digital I/O module, expanding the 3BHB000652R0101 for complex cell integration.

- ABB DSQC 652: A standard I/O board for the IRC5 controller, providing 16 DI/16 DO channels for basic sensor/actuator connectivity.

- ABB FlexPendant 12: A rugged handheld operator panel, enabling real-time robot programming and diagnostics for the KUC720AE101.

ABB LWN2660-6E

Installation and Maintenance

Pre-installation preparation: Mount the KUC720AE101 in an IRC5 controller cabinet with proper grounding and forced air cooling (airflow ≥2 m³/min). Connect the 3BHB003431R0101 and 3BHB000652R0101 using shielded backplane cables, ensuring secure locking of module latches. Configure IP addresses and robot models via RobotStudio®, calibrating encoder feedback for each axis using ABB’s Zero Position Calibration Tool.

Maintenance recommendations: Perform quarterly inspections of cooling fans and filter cartridges, replacing them if dust accumulation reduces airflow by >30%. Use RobotStudio®’s Condition Monitoring feature to track module health (e.g., CPU load, memory usage) and schedule firmware updates (biannually) to access new motion algorithms or safety patches. In high-vibration environments (e.g., stamping plants), retighten module screws (2.5 N·m) annually to prevent loose connections.

Product Guarantee

ABB stands behind the KUC720AE101 series with a 3-year warranty, covering hardware defects and firmware errors. ABB’s Robot Care Services provide 24/7 remote diagnostics and on-site support, with guaranteed response times <2 hours for critical failures. The module undergoes rigorous testing, including 10,000-hour continuous operation tests and EMC compliance (EN 61000-6-4), ensuring reliability in harsh factory environments. For customers requiring extended uptime, ABB offers Gold Service Agreements, including annual preventive maintenance and priority access to spare parts like the 3BHB003431R0101 CPU module. By combining precision control, safety innovation, and global service support, the KUC720AE101 series sets the standard for next-generation robotic automation.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.