Description

ABB MT-91-ARCFPA Operator Panel Product Documentation

1. Product Overview

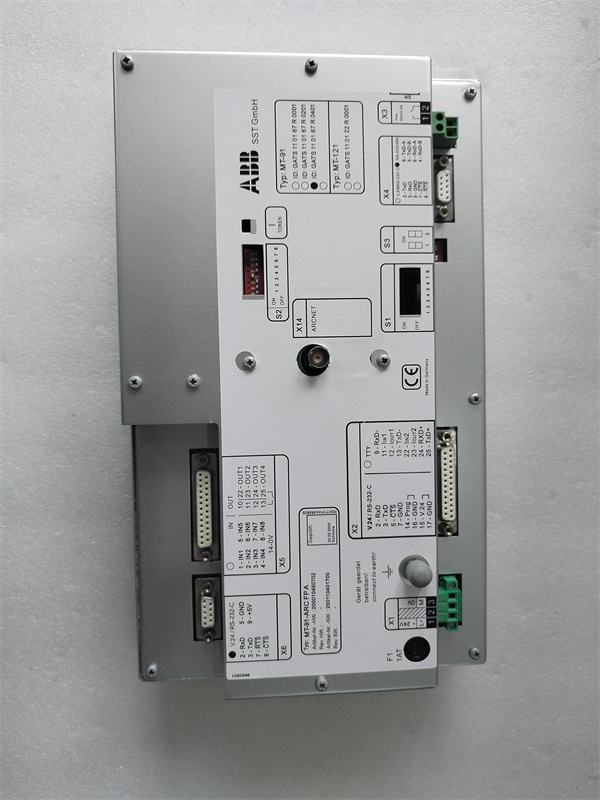

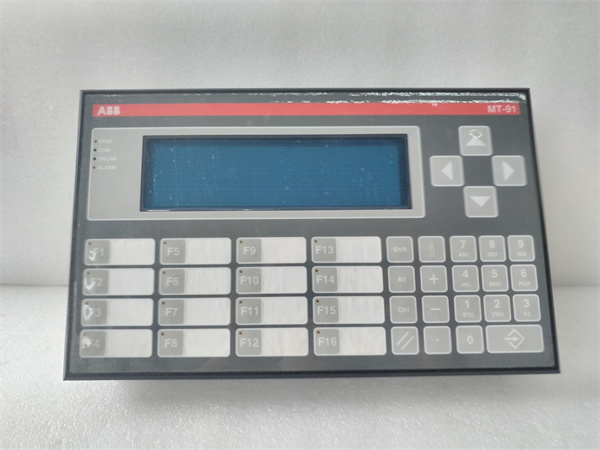

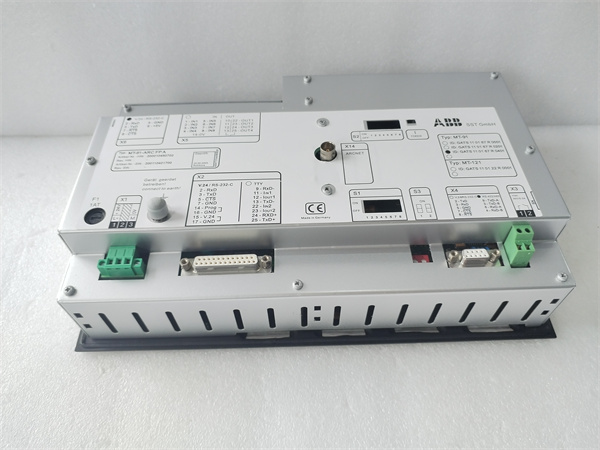

The ABB MT-91-ARCFPA is a rugged, compact operator panel designed for industrial automation and control applications. Engineered to serve as a human-machine interface (HMI), the MT-91-ARCFPA enables real-time monitoring and precise control of industrial processes in harsh environments. As part of ABB’s Synpol D series, this module combines durable construction with user-friendly functionality, making it ideal for industries requiring reliable HMI solutions. The MT-91-ARCFPA supports seamless integration with PLCs, drives, and sensors, facilitating efficient data exchange and system management. Its intuitive touchscreen and robust design ensure stable operation in challenging conditions, such as high vibrations, extreme temperatures, or dusty environments.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Brand & Model | ABB MT-91-ARCFPA |

| Type | Industrial Operator Panel (HMI) |

| Voltage Supply | 24 V DC (±10%) or 120 V AC (selectable) |

| Power Consumption | ≤5 W (typical operation) |

| Display | 5.7-inch color LCD touchscreen (320 x 240 pixels) |

| CPU | 16-bit microprocessor |

| Memory | 128 KB EEPROM, 32 KB RAM |

| Communication Interfaces | RS-422/485 (modular support for industrial networks) |

| I/O Channels | 16 digital inputs, 12 digital outputs (configurable) |

| Operating Temperature | -20°C to +60°C (-4°F to +140°F) |

| Storage Temperature | -40°C to +85°C |

| Environmental Resistance | IP54-rated (dust and water spray protection), vibration resistance (2g, 10–500 Hz) |

| Dimensions | 100 mm (W) × 150 mm (H) × 50 mm (D) |

| Mounting | DIN rail or panel mount |

| Certifications | CE, RoHS, IEC 61131-2 (industrial safety) |

MT-91-ARCFPA

3. Key Advantages & Features

-

Rugged Industrial Design:

- Durability: Withstands extreme temperatures (-20°C to +60°C) and IP54 protection, ensuring reliable operation in harsh environments like manufacturing floors, marine vessels, or chemical plants.

- Compact Form Factor: Space-saving design (100x150x50 mm) fits into tight control cabinets, optimizing panel space by up to 30% compared to larger HMIs.

-

Intuitive User Interface:

- Touchscreen Operation: High-contrast LCD touchscreen enables easy navigation for real-time process monitoring, parameter adjustment, and alarm management.

- Multi-Language Support: Pre-configured for 12+ languages, facilitating global deployment and reducing training time for operators.

-

Flexible Connectivity:

- Protocol Compatibility: Supports RS-422/485 for seamless integration with ABB drives (e.g., ACS800 series) and third-party PLCs, ensuring compatibility with both legacy and modern systems.

- Modular I/O: Configurable digital inputs/outputs allow direct connection to sensors and actuators, reducing the need for external modules.

-

Energy Efficiency:

- Low Power Consumption: Operates at ≤5 W, minimizing energy costs in 24/7 industrial applications.

4. Applications & Case Studies

The MT-91-ARCFPA is widely used in:

- Manufacturing: Machine control for conveyor systems, robotic arms, and quality inspection stations.

- Energy: Monitoring auxiliary systems in power plants or renewable energy installations (e.g., wind farm control panels).

- Marine: Shipboard automation for engine management, bilge pump control, and navigation systems.

- Process Industries: Chemical mixing, water treatment, and wastewater management.

Case Study:

A North American food processing plant integrated the MT-91-ARCFPA into its packaging line to monitor conveyor speeds and product flow. The panel’s RS-485 connectivity enabled real-time data exchange with the plant’s PLC, reducing downtime caused by miscommunication between devices by 20%. The intuitive touchscreen also allowed operators to adjust parameters on-the-fly, improving production efficiency by 15%.

A North American food processing plant integrated the MT-91-ARCFPA into its packaging line to monitor conveyor speeds and product flow. The panel’s RS-485 connectivity enabled real-time data exchange with the plant’s PLC, reducing downtime caused by miscommunication between devices by 20%. The intuitive touchscreen also allowed operators to adjust parameters on-the-fly, improving production efficiency by 15%.

5. Competitive Comparison

| Feature | ABB MT-91-ARCFPA | Market Equivalents |

|---|---|---|

| Temperature Range | -20°C to +60°C | 0°C to +50°C (average) |

| IP Rating | IP54 (dust/water spray) | IP42 (basic dust protection) |

| Power Consumption | ≤5 W | 8–10 W (typical) |

| I/O Flexibility | Configurable digital I/O | Fixed I/O channels |

| Multi-Language Support | Built-in (12+ languages) | Optional add-on |

MT-91-ARCFPA

The MT-91-ARCFPA outperforms comparable HMIs with its wider temperature tolerance, robust environmental protection, and native multi-language support, making it a more versatile choice for global industrial applications.

6. Selection Recommendations

- System Compatibility: Verify RS-422/485 compatibility with your existing control system (e.g., ABB PLCs or third-party devices).

- Environmental Needs: Choose the MT-91-ARCFPA for harsh environments with temperature fluctuations, dust, or moisture. For clean, controlled environments, consider smaller HMIs, but note this model’s superior durability.

- Scalability: Evaluate required I/O channels and communication protocols; the module’s configurable inputs/outputs are ideal for applications needing direct sensor/actuator integration.

- Budget: Balance upfront costs with long-term reliability; its low power consumption and minimal maintenance needs offer cost savings over less durable alternatives.

7. Installation & Maintenance Tips

- Electrostatic Discharge (ESD) Protection: Use anti-static wrist straps during handling to prevent damage to internal components.

- Wiring: Shielded cables are recommended for RS-422/485 connections to minimize electromagnetic interference (EMI).

- Firmware Updates: Regularly update firmware via ABB’s dedicated software to access new features and security patches.

- Routine Inspections: Check for loose connections and clean the touchscreen and vents quarterly to maintain optimal performance.

- Safety Compliance: Ensure installation meets local electrical codes (e.g., grounding requirements) and follows ABB’s guidelines for industrial safety.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for ABB MT-91-ARCFPA and other automation spare parts. Visit www.xydcontrol.com or contact us for sales and technical support.