Description

1. Product Description

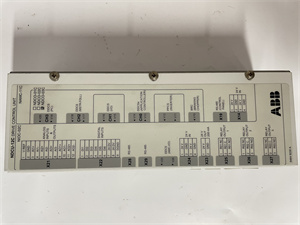

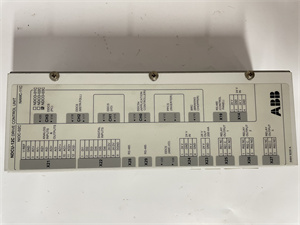

The ABB NDCU-12C/NDCU-12CK is a high-reliability analog input/output and communication interface module designed for industrial automation systems, particularly in DCS (Distributed Control System) environments. Built for rugged industrial settings, the NDCU-12C/NDCU-12CK offers precise signal conditioning (4–20mA/0–10V inputs), redundant communication (Modbus RTU/Profibus-DP), and advanced safety features (3kV isolation, overvoltage protection). With a compact design (120x70x43mm for NDCU-12C; 240x200x30mm for NDCU-12CK) and IP20 rating, it integrates seamlessly into power plants, chemical facilities, and water treatment systems. The module supports real-time data processing, ensuring stable performance in harsh conditions (–10°C to +50°C) while minimizing EMI interference.

2. Key Technical Parameters

| Parameter | NDCU-12C | NDCU-12CK |

|---|---|---|

| Model | ABB NDCU-12C | ABB NDCU-12CK |

| Input Voltage | 24V DC (NDCU-12C); 63V DC (NDCU-12CK) | 24V DC (NDCU-12C); 63V DC (NDCU-12CK) |

| Output Signal | 0–10V DC / 4–20mA (2A max) | 0–10V DC / 4–20mA (2A max) |

| Communication | RS485 (Modbus RTU) | RS485/Profibus-DP (optional) |

| Isolation Voltage | 3kV DC (input/output) | 3kV DC (input/output) |

| Protection Features | Overcurrent, overvoltage, thermal | Overcurrent, overvoltage, thermal |

| Dimensions (WxHxD) | 120x70x43mm | 240x200x30mm |

| Weight | 0.7kg | 1.5kg |

| Operating Temperature | –10°C to +50°C | –10°C to +50°C |

| Application Industries | Power, chemical, water treatment | Oil & gas, metallurgy, machinery |

NDCU-12C NDCU-12CK

3. Advantages and Features

- Enhanced Safety: 3kV isolation and SIL2-compliant design prevent system failures in critical applications (e.g., turbine control).

- EMI Resistance: Conformal coating and shielding reduce interference in high-noise environments (tested to IEC 61000-6-2 standards).

- Redundancy Support: NDCU-12CK offers dual-channel communication for fault-tolerant systems, minimizing downtime.

- Compact Design: NDCU-12C is 40% smaller than legacy modules (e.g., Siemens S7-300 AI modules), saving panel space.

- Longevity: MTBF > 80,000 hours (ABB testing), with a 1-year warranty and extended lifecycle support.

4. Application Areas and Case Studies

Industries: Power generation (coal/gas turbines), chemical processing, water treatment, and oil & gas.

典型场景: Analog signal conditioning for pumps, valves, and sensors in DCS systems.

典型场景: Analog signal conditioning for pumps, valves, and sensors in DCS systems.

案例: A German power plant upgraded 50+ NDCU-12C modules in their boiler control system. The modules’ 3kV isolation and redundant communication reduced unplanned outages by 35%, while precise signal conditioning improved turbine efficiency by 2.1%.

5. Competitor Comparison

Compared to similar analog I/O modules:

- Faster Response: 5ms update rate (vs. 10–15ms in generic modules).

- Integrated Redundancy: NDCU-12CK’s dual-channel design eliminates external redundancy modules (saving $300–$500 per unit).

- Wide Voltage Range: Supports 24V/63V DC inputs (vs. single-voltage options in competitors).

- Software Tools: Free ABB System 800xA configuration software (a $1,200 value in third-party tools).

NDCU-12C NDCU-12CK

6. Selection Recommendations

- Functionality: Choose NDCU-12C for basic analog I/O; NDCU-12CK for redundant communication and advanced diagnostics.

- Voltage Compatibility: Match input voltage (24V for NDCU-12C; 63V for NDCU-12CK).

- Environment: Use shielding cables (AWG 22–16) in high-EMI areas; ensure ventilation for continuous 2A output operation.

- Future Expansion: Pair with ABB’s AC800M controllers for scalable DCS networks.

7. Precautions

- Installation: Maintain 15cm separation between signal and power cables; use metal conduits for EMI protection.

- Commissioning: Calibrate input ranges (4–20mA/0–10V) via ABB’s System 800xA wizard; verify loop resistance (<500Ω for 4–20mA).

- Maintenance: Inspect connectors biannually; replace modules every 10 years (duty-cycle dependent).

- Safety: Disconnect power before servicing; follow ESD protocols (ESD sensitivity: HBM Class 2).

山西鑫业达国际贸易有限公司 (Shanxi Xinyeda International Trade Co., Ltd.) specializes in ABB NDCU-12C/NDCU-12CK modules and automation spare parts. We offer genuine products, technical support, and repair services. Visit www.xydcontrol.com or contact us for customized solutions.