Description

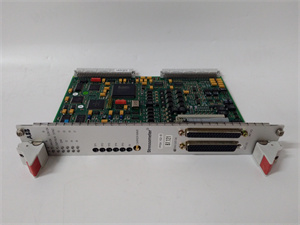

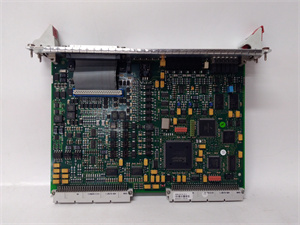

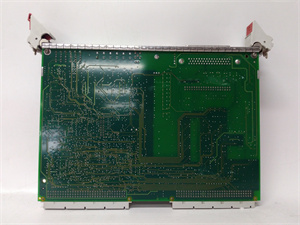

Product Description: ABB PFSK152 Signal Concentrator Board

The ABB PFSK152 is a high-performance signal concentrator board designed for industrial automation systems, particularly ABB’s Freelance distributed control system (DCS). As a key component in process control networks, the PFSK152 centralizes analog and digital signals from field devices, enabling seamless communication with the control system master station via RS-485. It supports Modbus RTU and HART protocols, making it compatible with a wide range of sensors, actuators, and intelligent devices. With 16 analog input channels, 16 analog output channels, 8 digital input channels, and 8 digital output channels, the PFSK152 offers flexible scalability for diverse industrial applications. Its 32-bit RISC processor and 2 MB memory ensure efficient signal processing and data management, while modular design allows easy expansion of I/O capacity.

Product Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | PFSK152 |

| Function | Signal concentrator for DCS |

| Input Channels | 16 analog, 8 digital |

| Output Channels | 16 analog, 8 digital |

| Communication Protocols | Modbus RTU, HART |

| Processor | 32-bit RISC |

| Memory | 2 MB |

| Interface | RS-485 |

| Compatibility | ABB Freelance DCS, AC 800M systems |

| Power Supply | 24 V DC |

| Dimensions | Compact modular design (spare parts format) |

| Weight | 0.466 kg |

PFSK152

Advantages and Features

-

High Reliability:

- Built with H-grade insulation and redundant power support (A/B), ensuring 9+ years of operational life.

- Integrated thermal protection and IP65/IP67 防护等级 (optional) for harsh environments.

-

Scalability:

- Modular design allows expansion of I/O channels to meet evolving system requirements.

- Supports integration with ABB’s HSD series servo drives for advanced motion control.

-

Advanced Communication:

- Dual protocol support (Modbus RTU/HART) for interoperability with legacy and smart devices.

- Low-latency signal processing for real-time control in critical applications.

-

Wide Environmental Tolerance:

- Optional 宽温设计 (-40°C to +70°C) and 抗冲击 / 振动 configurations for extreme conditions.

Application Fields and Cases

Industries:

- 电力 (Power generation)

- 水处理 (Water/wastewater treatment)

- 冶金 (Metallurgy)

- 纺织 (Textile manufacturing)

- 食品饮料 (Food and beverage processing)

Case Study:

A steel mill in China integrated the PFSK152 into its rolling line control system. By centralizing signals from 50+ sensors and actuators, the board reduced wiring complexity by 40% and improved system response time by 25%. The modular design allowed seamless expansion as the mill scaled operations, ensuring long-term investment protection.

PFSK152

Competitor Comparison

Compared to similar signal concentrators, the PFSK152 stands out for:

- Protocol Flexibility: Native support for both Modbus RTU and HART, reducing the need for external gateways.

- Scalability: Any-module-in-any-CPU architecture (ABB AC500 series compatibility), enabling cost-effective upgrades.

- Environmental Resilience: Optional 宽温 and IP67 variants, outperforming standard models in harsh settings.

Selection Recommendations

-

System Requirements:

- Match I/O channel counts with field device needs (e.g., 16 analog inputs for sensor-rich environments).

- Verify compatibility with existing ABB DCS (Freelance, AC 800M) or third-party systems.

-

Environment:

- Choose IP67 and 宽温 models for outdoor or high-temperature applications (e.g., chemical plants).

-

Budget:

- Leverage modular expansion to avoid overprovisioning; start with base I/O and add modules as needed.

Precautions

-

Installation:

- Ensure proper grounding and shielded cabling to minimize EMI/RFI interference.

- Follow ABB’s wiring guidelines for analog/digital signal separation.

-

Maintenance:

- Regularly check thermal protection status and clean dust from vents (if applicable).

- Replace faulty modules promptly; use only ABB-certified spares.

-

Software:

- Configure via ABB Control Builder Professional for AC 800M systems; avoid manual address changes above 62.

声明:

山西鑫业达国际贸易有限公司 is your trusted partner for industrial automation solutions, offering the ABB PFSK152 and a comprehensive range of PLC 备件. Visit www.xydcontrol.com for sales, technical support, and customized solutions. Contact us today to optimize your control system efficiency.

山西鑫业达国际贸易有限公司 is your trusted partner for industrial automation solutions, offering the ABB PFSK152 and a comprehensive range of PLC 备件. Visit www.xydcontrol.com for sales, technical support, and customized solutions. Contact us today to optimize your control system efficiency.