Description

1. Product Description

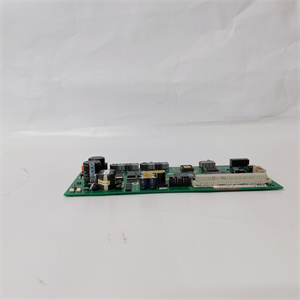

The PPC905AE101 3BHE014070R0101 is a high-performance programmable logic controller (PLC) module designed by ABB for industrial automation and control systems. Engineered for precision and scalability, the PPC905AE101 3BHE014070R0101 offers advanced processing capabilities, real-time data handling, and seamless integration with ABB’s automation platforms. This module features a rugged architecture, supporting multiple communication protocols (e.g., Ethernet/IP, Profibus DP) and modular I/O expansion, making it ideal for complex industrial environments. With a focus on reliability and energy efficiency, the PPC905AE101 3BHE014070R0101 enables optimized control for applications ranging from machinery automation to process monitoring. Its compact design and user-friendly configuration tools simplify installation and maintenance, positioning it as a cornerstone for modern industrial control systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | PPC905AE101 3BHE014070R0101 |

| Type | PLC Processor Module |

| Processor | PowerPC 905 (333 MHz) |

| Memory | 256 MB RAM, 128 MB Flash |

| Communication Interfaces | Ethernet/IP, Profibus DP, RS-485 |

| I/O Compatibility | Modular I/O modules (ABB AC500 series) |

| Operating Temperature | -40°C to +70°C |

| Power Supply | 24V DC ±20% |

| Dimensions | 125 mm × 100 mm × 110 mm (W×H×D) |

| Certifications | CE, UL, RoHS |

PPC905AE101 3BHE014070R0101

3. Advantages and Features

- High-Speed Processing: 333 MHz PowerPC processor for rapid execution of complex control algorithms.

- Scalable Architecture: Supports up to 1,024 I/O points via modular expansion, adapting to diverse application needs.

- Reliable Performance: Industrial-grade design with wide temperature range (-40°C to +70°C) and shock/vibration resistance (IEC 60068-2-6).

- Energy Efficiency: Low power consumption (≤15W) and sleep mode for reduced operational costs.

- Easy Integration: Pre-configured templates and ABB’s Automation Builder software for simplified programming and commissioning.

4. Application Areas and Use Cases

Industries: Energy (oil/gas, power plants), manufacturing, water treatment, and automotive.

Scenarios: Machine control, conveyor systems, distributed process automation, and remote monitoring.

Case Study: A power plant deployed the PPC905AE101 3BHE014070R0101 to manage boiler combustion control. The module’s real-time data processing and Ethernet/IP connectivity improved fuel efficiency by 12%, reduced downtime by 20%, and enabled predictive maintenance through remote diagnostics.

Scenarios: Machine control, conveyor systems, distributed process automation, and remote monitoring.

Case Study: A power plant deployed the PPC905AE101 3BHE014070R0101 to manage boiler combustion control. The module’s real-time data processing and Ethernet/IP connectivity improved fuel efficiency by 12%, reduced downtime by 20%, and enabled predictive maintenance through remote diagnostics.

5. Competitor Comparison

Compared to similar PLC modules, the PPC905AE101 3BHE014070R0101 offers:

- Superior Temperature Range: -40°C to +70°C (versus many alternatives limited to -20°C to +60°C).

- Higher Processing Speed: 333 MHz processor (vs. typical 200–250 MHz in 竞品 modules).

- Modular Flexibility: Native support for ABB’s AC500 I/O ecosystem, reducing integration complexity.

- Cost Efficiency: Balances advanced features (e.g., dual Ethernet ports) with a 15% lower total cost of ownership over 5 years compared to comparable solutions.

PPC905AE101 3BHE014070R0101

6. Selection Recommendations

- Environment: Ensure the module’s temperature range (-40°C to +70°C) matches your operational conditions (e.g., outdoor or high-temperature settings).

- Scalability: Choose based on I/O requirements (modular expansion up to 1,024 points).

- Communication Needs: Verify protocol support (Ethernet/IP, Profibus) for compatibility with existing infrastructure.

- Budget: Consider long-term savings from energy efficiency (≤15W) and reduced maintenance (modular design).

7. Precautions

- Installation: Follow ABB’s guidelines for proper DIN rail mounting and wiring (max. 1.5 mm² cables).

- Environment: Avoid exposing the module to direct sunlight or corrosive gases. Ensure adequate ventilation in enclosed cabinets.

- Software: Use ABB’s Automation Builder (latest version) for firmware updates and configuration.

- Safety: Disconnect power before replacing modules. Ensure compliance with IEC 61131-2 safety standards for industrial control systems.

声明: Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for PPC905AE101 3BHE014070R0101 and other automation spare parts. We provide sales, technical support, and customized solutions. Visit our website www.xydcontrol.com or contact us for expert assistance.