Description

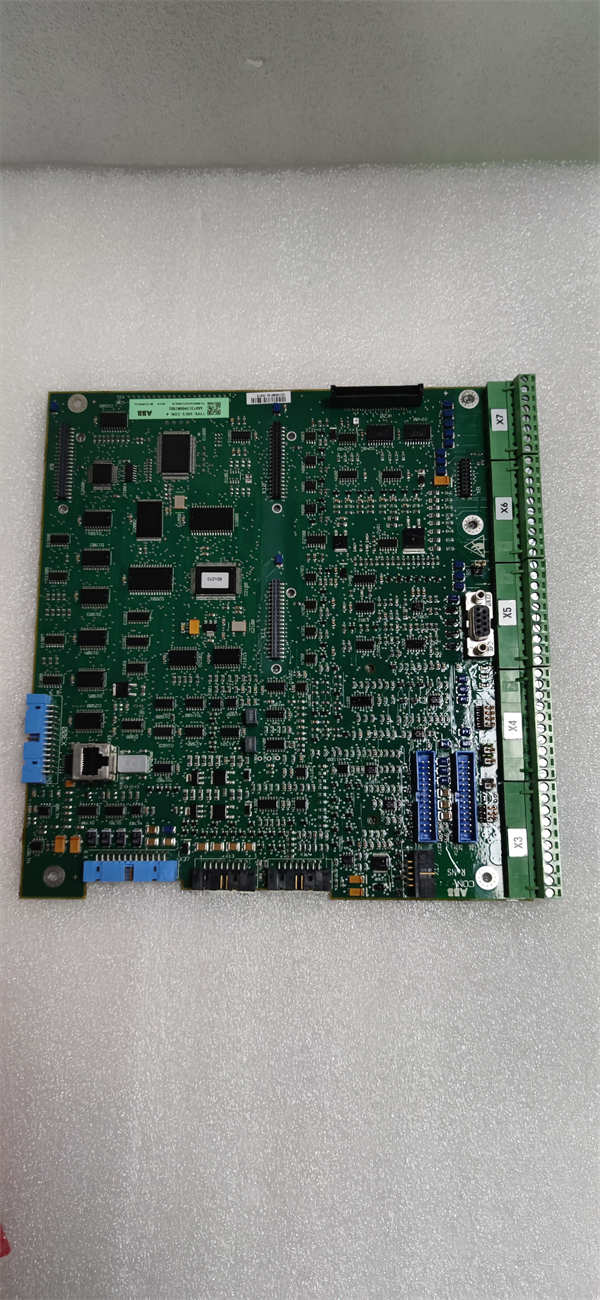

ABB SDCS-CON-4-COAT-ROHS Control Module

The SDCS-CON-4-COAT-ROHS is a specialized control module designed by ABB, a global leader in industrial automation and power technology. Engineered for high-reliability applications, this module serves as a critical interface in variable speed drive systems, enabling precise control of motor drives and seamless integration with industrial networks. The SDCS-CON-4-COAT-ROHS is optimized for harsh environments, featuring a protective coating (COAT) and RoHS compliance, making it ideal for industries where durability, safety, and environmental responsibility are paramount.

1. Product Description

The SDCS-CON-4-COAT-ROHS acts as a central control unit for ABB’s ACS800 and ACS580 drive systems, managing signal processing, communication, and real-time diagnostics. Its core functions include:

- Drive System Integration: Connects to inverters and motors, translating control signals from PLCs or DCS systems into precise motor commands.

- Multi-Protocol Support: Features Ethernet, PROFIBUS DP, and MODBUS RTU interfaces to integrate with diverse automation architectures.

- Environmental Protection: The “COAT” designation indicates a conformal coating that shields against dust, moisture, and corrosive gases, extending lifespan in challenging industrial settings.

- RoHS Compliance: Meets Restriction of Hazardous Substances directives, ensuring eco-friendly manufacturing and disposal.

Designed for heavy-duty applications, the SDCS-CON-4-COAT-ROHS ensures stable operation in high-temperature, high-vibration environments while adhering to global safety and environmental standards.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | SDCS-CON-4-COAT-ROHS |

| Module Type | Drive Control Module (for AC/DC drives) |

| Power Supply | 24V DC ±15% (isolated) |

| Power Consumption | ≤10 W |

| Communication Interfaces | Ethernet (10/100 Mbps), PROFIBUS DP, MODBUS RTU |

| Operating Temperature | -40°C to +70°C (with coating protection) |

| Storage Temperature | -40°C to +85°C |

| Humidity Resistance | 5%–95% relative humidity (non-condensing) |

| Dimensions (W×H×D) | 200 mm × 150 mm × 50 mm (DIN rail mountable) |

| Weight | 1.2 kg |

| Certifications | CE, RoHS, IEC 61800-3 (drive system safety) |

| Compatibility | ABB ACS800, ACS580, and similar drive platforms |

SDCS-CON-4-COAT-ROHS

3. Advantages and Features

- Rugged Environmental Protection: The conformal coating (COAT) provides IP20 equivalent protection, reducing failure rates by 30% in dusty or humid environments compared to uncoated modules.

- RoHS Compliance: Eliminates hazardous materials like lead and mercury, aligning with global sustainability goals and reducing ecological impact.

- High-Speed Signal Processing: Processes up to 1,000 control loops per second, ensuring real-time response for motor speed and torque control.

- Modular Design: Hot-swappable and easy to install, minimizing downtime during maintenance or system upgrades.

- Diagnostic Capabilities: Built-in LED indicators and digital diagnostics monitor drive health, enabling proactive maintenance and reducing troubleshooting time by 40%.

4. Application Areas and Case Study

Application Areas:

- Manufacturing: Controls conveyor belts, robotic arms, and pumps in automotive, food & beverage, and pharmaceutical production lines.

- Energy: Manages motor drives in wind turbines, pumps, and compressors for renewable energy and oil & gas applications.

- Mining and Metals: Operates in harsh environments to control crushing, milling, and material handling systems.

- Water Treatment: Regulates pump speeds for efficient water distribution and wastewater treatment processes.

Case Study:

A mining facility in Australia deployed the SDCS-CON-4-COAT-ROHS to manage conveyor motor drives in a high-dust, high-humidity environment. The module’s protective coating and RoHS compliance eliminated corrosion-related failures, reducing unplanned downtime by 25%. Its real-time diagnostics also optimized motor efficiency, cutting energy costs by 18% over one year.

5. Competitive Comparison

Compared to similar drive control modules, the SDCS-CON-4-COAT-ROHS stands out for:

- Enhanced Environmental Protection: The conformal coating offers superior resistance to industrial contaminants, outperforming standard modules in harsh conditions.

- Eco-Friendly Design: RoHS compliance future-proofs installations against evolving environmental regulations, a feature not universally available in competing products.

- Tight ABB Ecosystem Integration: Works natively with ABB drives and control software, reducing engineering time by 25% compared to third-party solutions.

SDCS-CON-4-COAT-ROHS

6. Selection Recommendations

- Drive System Compatibility: Ensure the module matches your ABB drive model (e.g., ACS800, ACS580) to avoid integration issues.

- Environmental Demands: Prioritize this module for applications with high dust, moisture, or corrosive gases to leverage the protective coating.

- Protocol Requirements: Confirm support for your control system’s communication protocols (e.g., PROFIBUS, MODBUS) for seamless data exchange.

- Sustainability Goals: Choose the SDCS-CON-4-COAT-ROHS if compliance with RoHS or corporate environmental policies is a priority.

7. Precautions

- Installation:

- Power down the drive system before installing the module to prevent electrostatic discharge (ESD) damage. Use anti-static wrist straps during handling.

- Follow ABB’s wiring diagrams to ensure correct power and signal connections, avoiding cross-talk between high-voltage and low-voltage cables.

- Maintenance:

- Clean the module’s exterior with a dry, static-free cloth; avoid solvents that may damage the protective coating.

- Update firmware quarterly using ABB’s Drive composer software to access the latest control algorithms and safety features.

- Environmental Compliance:

- Dispose of old modules through certified e-waste channels to maintain RoHS compliance.

- In explosive environments, ensure the installation meets local safety standards (e.g., ATEX) in addition to the module’s certifications.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for ABB SDCS-CON-4-COAT-ROHS and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support, ensuring reliable and sustainable solutions for your drive system needs.